Solar wing flexible simulator

A simulator and wing flexibility technology, applied in the aerospace field, can solve the problems of impossible, difficult frequency accurate simulation, inability to simulate different moments of inertia, etc., to achieve the effect of strong practicability and accurate simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

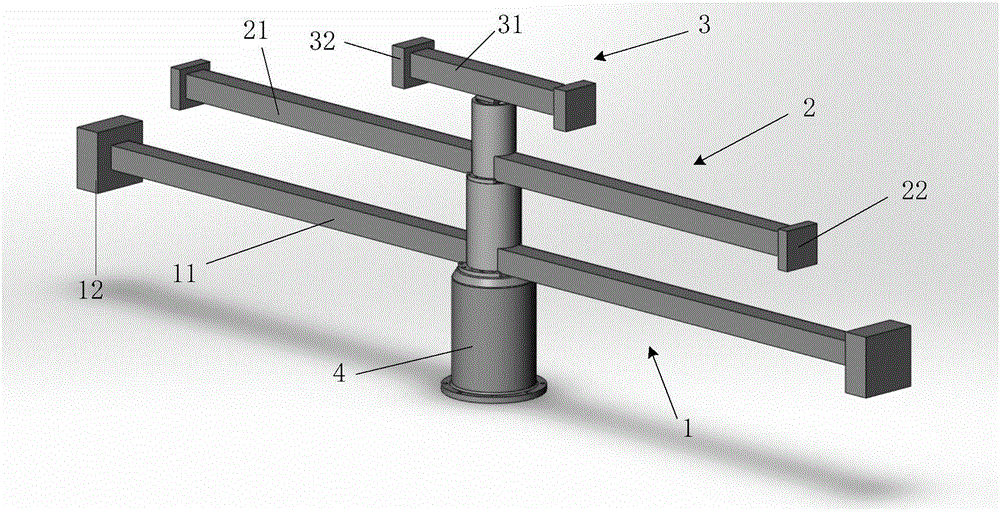

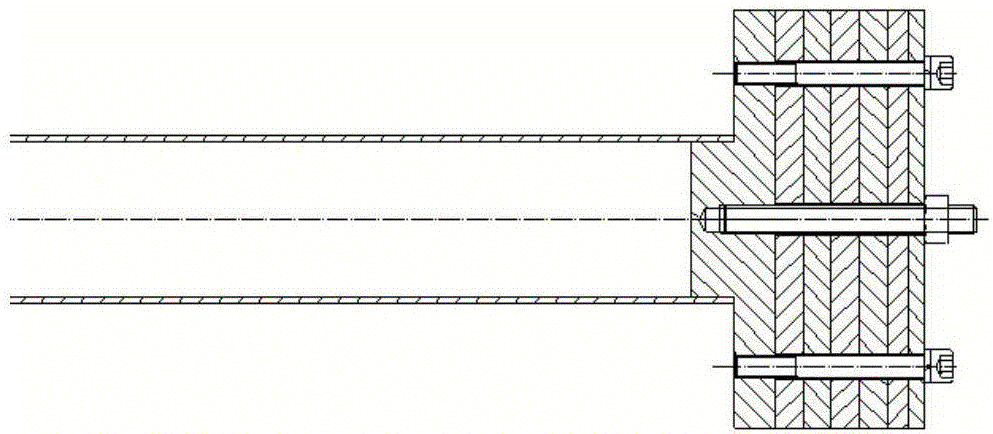

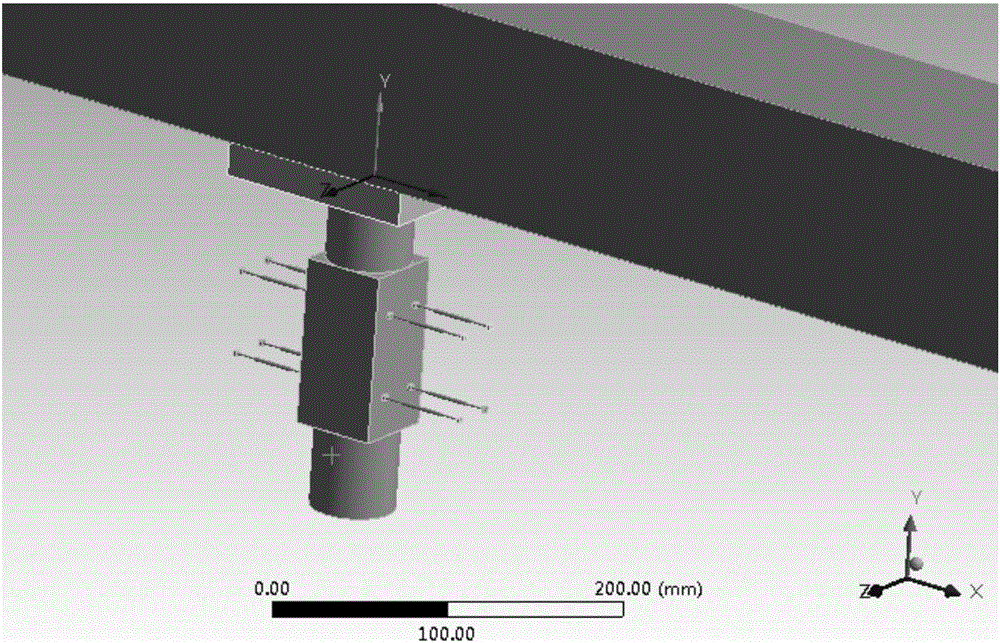

[0043] In order to make the objectives, technical solutions, and advantages of the present invention clearer and more comprehensible, the present invention will be further described in detail with reference to the accompanying drawings and preferred embodiments. However, it should be noted that many details listed in the specification are only to enable the reader to have a thorough understanding of one or more aspects of the present invention, and these aspects of the present invention can be implemented even without these specific details.

[0044] The inventor of the present invention considers that when a spacecraft is flying in orbit, it is prone to be affected by various propulsive forces to produce large vibrations. The coupling between the vibration of the flexible attachment and the motion of the spacecraft body will affect the attitude of the spacecraft. Stability and orientation accuracy have an impact, and even damage the instrument to invalidate the spacecraft. There...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com