Numerical control machine tool unobservable link simulation method and device, terminal and storage medium

A technology of CNC machine tools and simulation methods, applied in neural learning methods, design optimization/simulation, comprehensive factory control, etc., can solve problems such as no CNC machine tool simulation, and achieve the effect of accurate simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

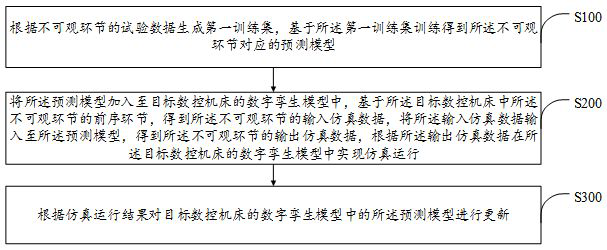

[0045] like figure 1As shown, an embodiment of the method for simulating invisible links of a CNC machine tool includes the steps of:

[0046] S100. Generate a first training set according to the test data of the invisible link, and obtain a prediction model corresponding to the invisible link through training based on the first training set.

[0047] The invisible links may be directly purchased black-box components whose internal structure and specific working principles are unknown, such as gearboxes, packaged transformers, etc., and due to the influence of actual manufacturing errors, operating environment, and service life, the unobservable links are not known. The output of the appreciable link will not exactly match the theoretical design value. When the invisible link exists independently, its output data can be collected, such as the output torque and output speed of the gearbox, which can be obtained by installing test equipment in the laboratory, but when the invis...

Embodiment 2

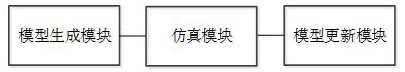

[0085] Based on the above embodiments, the present invention also provides a corresponding simulation device for invisible links of CNC machine tools, such as figure 2 As shown, the simulation device for the invisible links of the CNC machine tool includes:

[0086] A model generation module, the model generation module is used to generate a first training set according to the test data of the invisible link, and obtain the prediction model corresponding to the invisible link based on the training of the first training set, which is specifically as described in the first embodiment. stated;

[0087] A simulation module, which is used to add the prediction model to the digital twin model of the target CNC machine tool, and obtain the input of the invisible link based on the pre-order link of the invisible link in the target CNC machine tool Simulation data, input the input simulation data into the prediction model, obtain the output simulation data of the invisible link, and ...

Embodiment 3

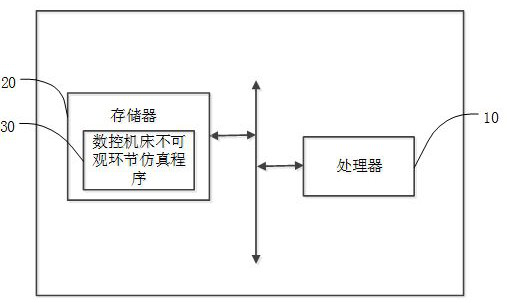

[0090] Based on the above embodiments, the present invention also provides a terminal correspondingly, such as image 3 As shown, the terminal includes a processor 10 and a memory 20 . image 3 Only some components of the terminal are shown, but it should be understood that implementation of all shown components is not required, and more or less components may be implemented instead.

[0091] In some embodiments, the memory 20 may be an internal storage unit of the terminal, such as a hard disk or a memory of the terminal. In other embodiments, the memory 20 may also be an external storage device of the terminal, for example, a plug-in hard disk, a smart memory card (Smart Media Card, SMC), a secure digital (Secure Digital, SD card) equipped on the terminal. ) card, Flash Card, etc. Further, the memory 20 may also include both an internal storage unit of the terminal and an external storage device. The memory 20 is used for storing application software and various types of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com