Automatic dispersing-type gummed paper laminating machine

A decentralized laminating machine technology, applied in the direction of winding strips, sending objects, thin material processing, etc., can solve problems such as inability to laminate, low work efficiency, and long labor time, so as to ensure product quality, The effect of improving production efficiency and reducing labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate those skilled in the art to understand the present invention, the present invention will be further described in detail below in conjunction with specific embodiments and accompanying drawings.

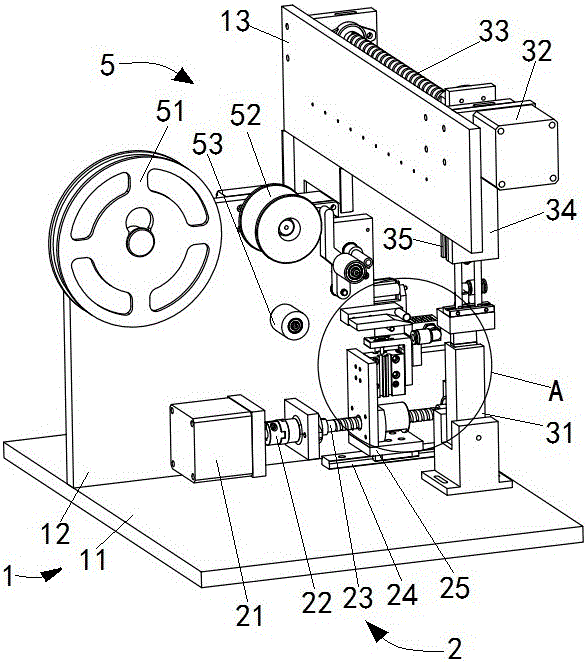

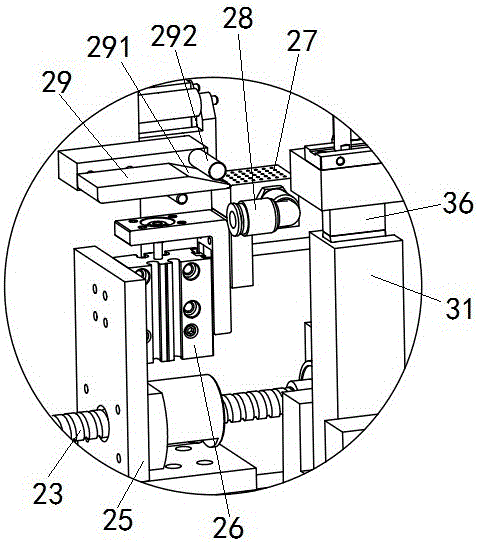

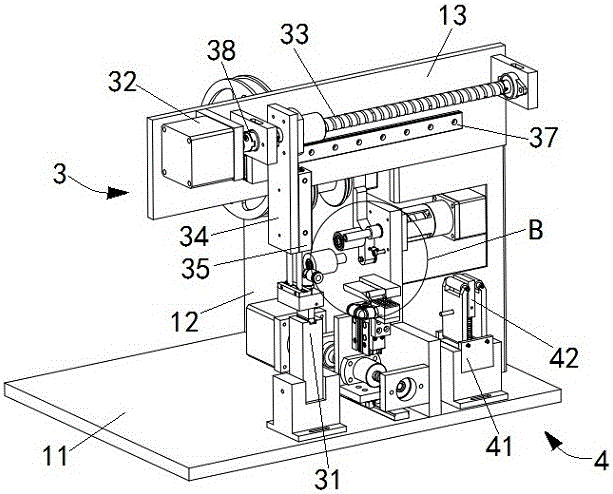

[0033] The driving parts used in this embodiment are all stepping motors, and the dispersed adhesive tape used is copper foil.

[0034] refer to Figure 1~8 , the dispersion-type glued paper automatic laminating machine provided by the present invention comprises a support mechanism 1, is located on the support mechanism 1 and is used for taking off the material take-off mechanism 2 of copper foil from the material belt, is used for taking off the material take-off mechanism The bonding mechanism 3 that sticks the copper foil to the battery, the pressing mechanism 4 that cooperates with the bonding mechanism 3 to tightly bond the copper foil to the battery, and the retracting and discharging mechanism 5 for retracting and discharging the tape.

[0035] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com