Power cable winding device

A winding device and a technology for power cables, which are applied in the directions of transportation and packaging, transportation of filamentous materials, and thin material handling, etc., can solve the problems of loose cable ends, easy disconnection, and influence on the firm winding of cables. , to achieve the effect of high compressive strength, high winding efficiency, and improved bearing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

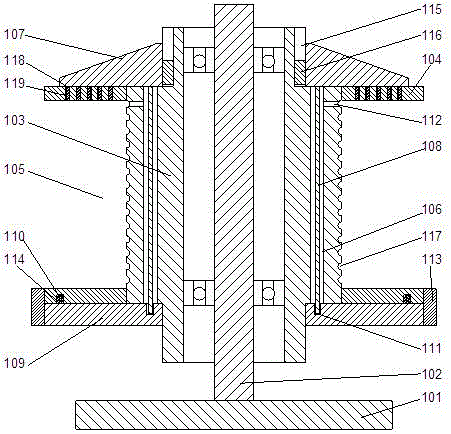

[0022] In this embodiment, in order to facilitate fixing the chassis, preferably, a bent portion 113 is provided on the outer edge of the baffle plate 104 near the side of the chassis 101, so that the bent portion is perpendicular to the side The baffle plate, the counterbore and the positioning hole 111 are all bar-shaped holes, and the outer end surface of the bottom cover 109 is screwed to the inner end surface of the bending portion 113 . When the bottom cover is screwed to the inside of the bending part, the cylindrical pin is clamped on the inside of the counterbore, and the end of the pressure rod away from the gland is inserted into the positioning hole, and the bottom cover is relatively fixed on the baffle by using the screw connection structure. At the same time, use the relatively fixed bottom cover to fix the end of the cable hooked on the pressure rod.

Embodiment 2

[0024] In this embodiment, on the basis of Embodiment 1, in order to improve the stability of the bottom cover, the cross-section of the cylindrical pin 110 has a T-shaped structure, and the inside of the counterbore is provided with a retaining edge 114 to make the counterbore A T-shaped slot is formed, and the cylindrical pin 110 can be inserted into the inner side of the retaining edge 114 . Use a T-shaped cylindrical pin to clamp the cylindrical pin inside the counterbore, then rotate the bottom cover relatively so that the cylindrical pin is clamped inside the retaining edge, and then use the cylindrical pin and the retaining edge to cooperate so that the bottom cover cannot move toward the The direction movement of the chassis can improve the stability of the bottom cover.

Embodiment 3

[0026] In the present invention, in order to facilitate the winding of cables inside the cavity, preferably, a wiring groove 117 is provided on the sleeve 103 inside the cavity 105, and the wiring groove 117 is arranged along the The outer wall of the casing 103 is helically arranged. When winding the cables, the innermost cables are wound in the wiring slots, which is conducive to the regular winding of the cables and makes the winding efficiency of the cables higher.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap