Self-bearing type grass brick house and construction process thereof

A technology for straw bricks and brick houses is applied in the field of self-supporting straw brick houses and their construction technology, which can solve the problems of increasing the cost of the frame, being uneconomical, and the thickness of the plastering layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

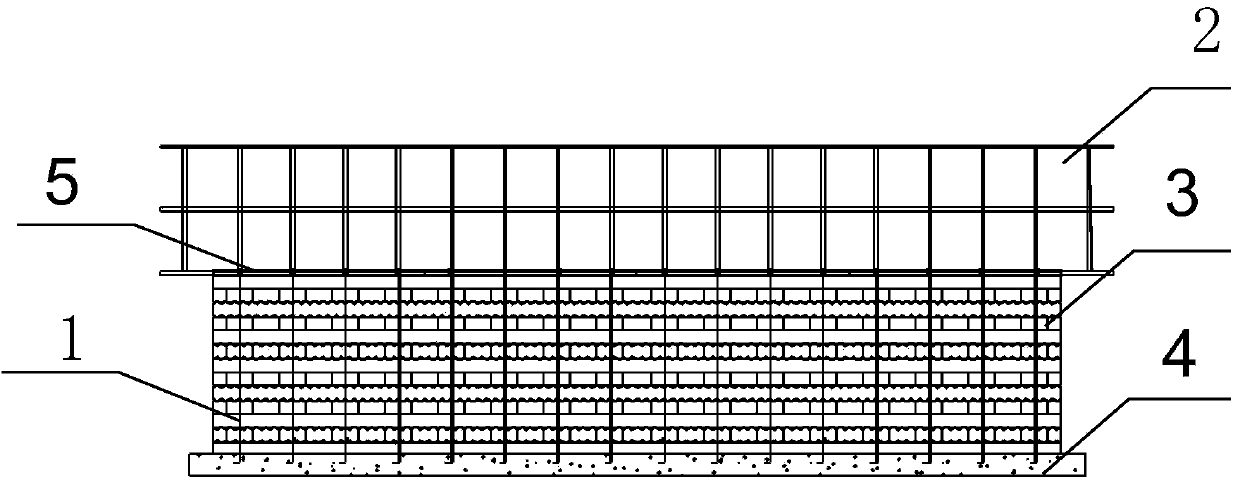

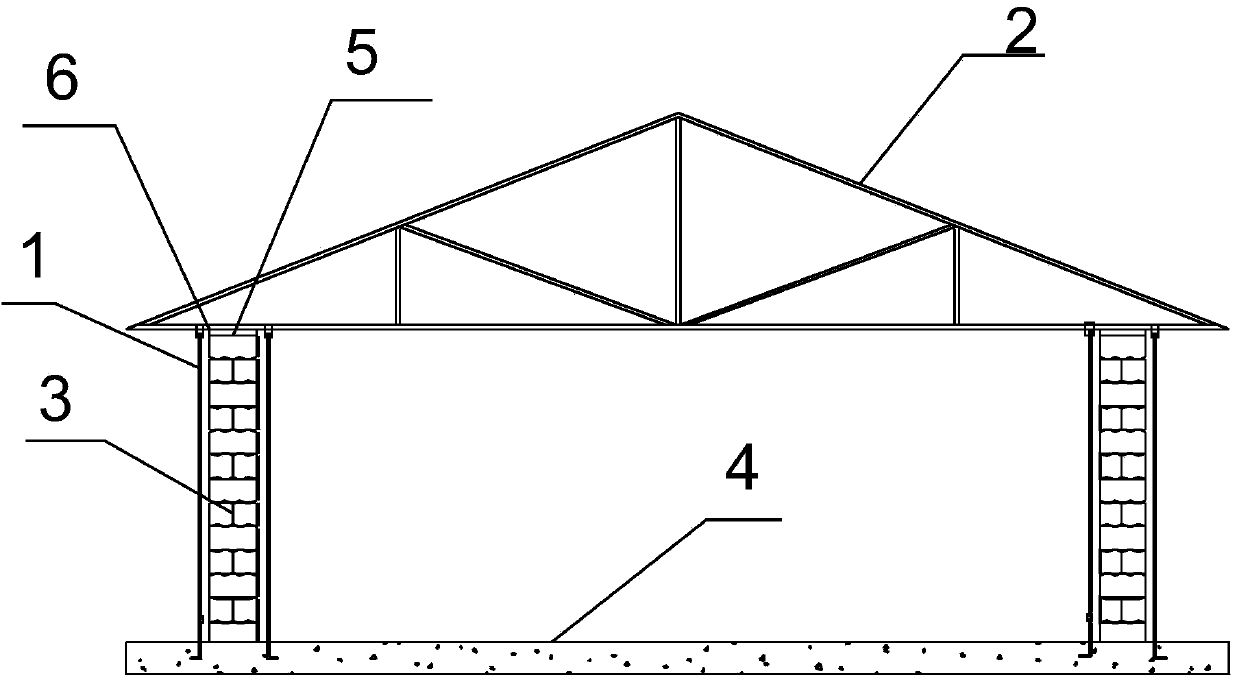

[0023] As shown in the figure, the construction process of the present invention includes the following steps: first use grass bricks to be staggered to form a grass brick wall; then set a pressure plate continuously on the top of the grass brick wall along the extension direction of the wall; then the pressure plate passes through at least two ends The linear connection part presses the bottom surface of the connected grass-brick house, and the linear connection part provides the pre-compression force of the grass-brick wall, which is greater than the maximum load-bearing pressure required by the building; finally, it is installed on both sides of the grass-brick wall Hard finish. The hard facing here is to apply cement...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap