Forklift working device with oblique air cylinders

A technology of working device and cylinder, applied in the direction of lifting device, etc., can solve the problem that the function of the forklift cannot adapt to the needs of various working conditions, and achieve the effects of reducing repeated purchases, convenient operation and maintenance, and safe and reliable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

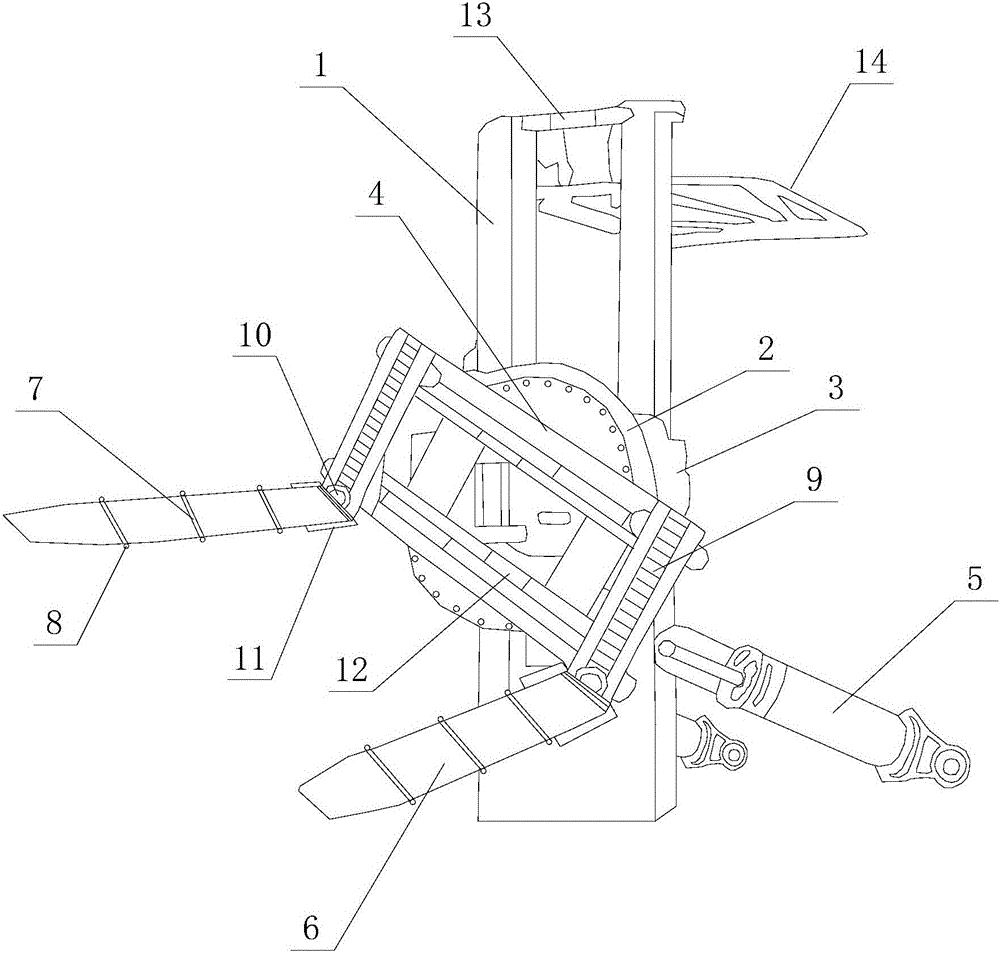

[0018] Such as figure 1 As shown, a forklift working device with tilting cylinders includes a mast 1, two sides of the lower part of the mast 1 are respectively connected with tilting cylinders 5, the mast 1 is provided with a rotator 2, and the rotator 2 passes through sliding parts on both sides 3 It is slidably arranged up and down on the door frame 1, the rotator 2 is provided with a fork frame 4, and the fork frame 4 is rotatably arranged on the door frame 1 by the rotator 2. The fork frame 4 is provided with two sliding guide devices, two sliding guides. There is a pitch adjusting device between the guides. Each sliding guide is connected to a fork 6. The fork 6 is provided with a plurality of elbows 7 for adjusting the shape of the fork. The fixed bolt 8, the sliding guide device is composed of a guide groove 9 and a sliding block 10. The sliding block 10 is slidably arranged in the guide groove 9, and the sliding block 10 is connected to one end of the fork 6 through a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com