Pressure drainage device

A technology of pressure and drainage tubes, applied in distribution devices, special distribution devices, packaging, etc., can solve the problems of bucket scrapping, waste, aging of water outlet and water cylinder sealing ring, etc., and achieve the effect of eliminating water leakage and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

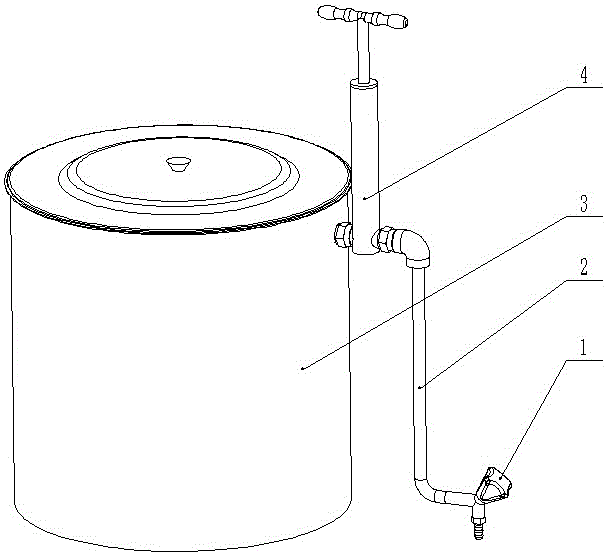

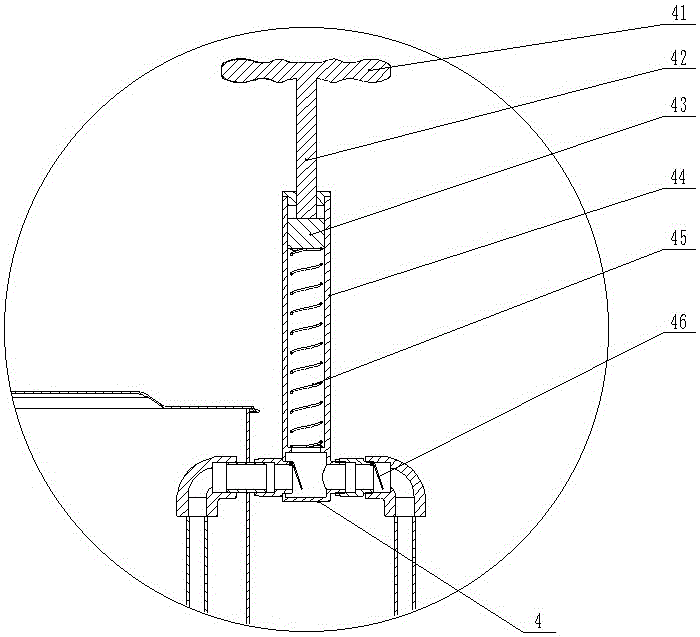

[0014] A pressure drainage device, comprising a drainage tube 2, a bucket 3, and a piston mechanism 4, one end of the drainage tube 2 is located at the bottom of the bucket 3, and the other end passes through the upper part of the bucket 3 at a level lower than the water level in the bucket 3 Draw below, piston mechanism 4 is installed on the drainage pipe 2 outside bucket, and one end of piston mechanism 4 is provided with inlet and outlet, and import, outlet are equipped with check valve 46 respectively, and the bottom of piston 43 is equipped with spring 45, piston rod 42 One end of the handle 41 is equipped with.

[0015] First open the valve 1 at the outlet of the drainage tube 2, when the handle 41 is pressed down, the one-way valve 46 at the inlet of the piston mechanism 4 is closed under pressure, and the one-way valve 46 at the outlet of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com