A kind of micro-surfacing mixture with snow-melting function and preparation method thereof

A technology of micro-surface mixture and function, which is applied in the field of micro-surface mixture with snow melting function and its preparation, which can solve the problems of salt loss and poor stability, delay snow freezing and improve cohesion , Improve the effect of cohesion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

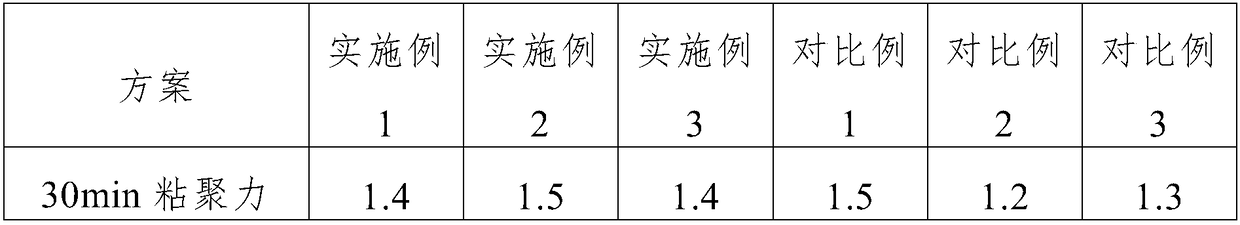

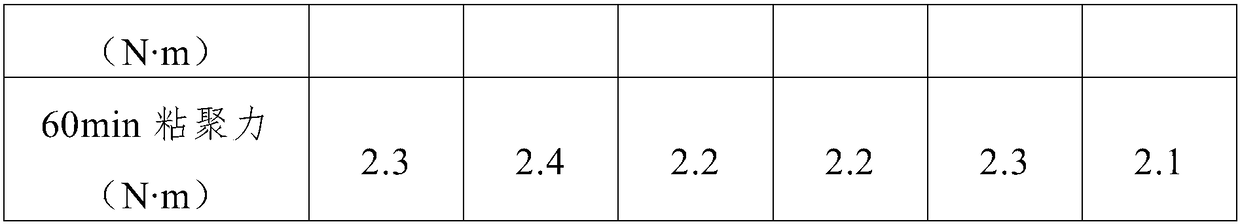

Examples

Embodiment 1

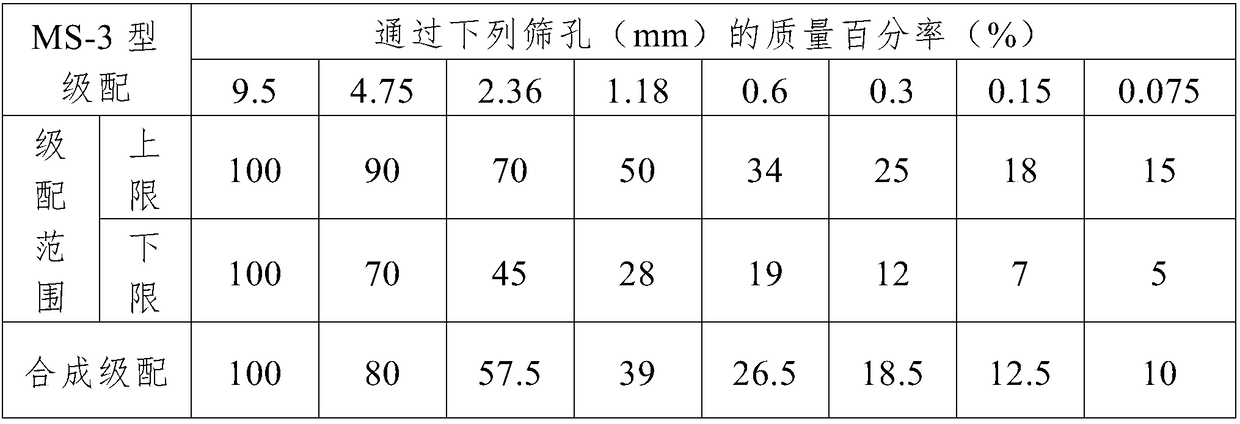

[0026] The micro-surface mixture with snow melting function in this embodiment is made of the following raw materials by weight: 74.5 parts of aggregate, 8 parts of SBR modified emulsified asphalt, 5 parts of mineral powder, 7 parts of water, 1.5 parts of cement, microcapsule phase 2 parts of variable material, 2 parts of acetic acid snow melting agent; the nominal maximum particle size of the aggregate is not more than 9.5mm, and the particle size of the mineral powder is less than 0.075mm. The grade of the micro-surface mixture with snow melting function in this embodiment The matching type is MS-3, and the specific grading composition is shown in Table 1;

[0027] Table 1 MS-3 gradation design of the mixture at the micro-surface

[0028]

[0029] In this example, the weight of each component of the microcapsule phase change material is 70 parts of paraffin wax, 8 parts of zinc oxide (heat transfer agent), 7 parts of activated clay (anti-supercooling agent), and polymer water-abs...

Embodiment 2

[0035] The micro-surface mixture with snow melting function in this embodiment is made of the following raw materials by weight: 73.8 parts of aggregate, 8 parts of SBR modified emulsified asphalt, 5 parts of mineral powder, 8 parts of water, 1.2 parts of cement, microcapsule phase 1 part of variable material, 3 parts of acetic acid snow melting agent; the nominal maximum particle size of the aggregate is not more than 9.5mm, and the particle size of the mineral powder is less than 0.075mm. The grade of the micro-surface mixture with snow melting function in this embodiment The matching type is MS-3, and the specific grading composition is shown in Table 1;

[0036] In this example, the weight of each component of the microcapsule phase change material is 70 parts of paraffin wax, 8 parts of zinc oxide (heat transfer agent), 7 parts of activated clay (anti-supercooling agent), and polymer water-absorbing resin (anti-phase separation agent) ) 5 parts, melamine-formaldehyde resin 1...

Embodiment 3

[0042] The micro-surface mixture with snow melting function in this embodiment is made of the following raw materials by weight: 73.5 parts of aggregate, 8 parts of SBR modified emulsified asphalt, 5 parts of mineral powder, 8 parts of water, 1.5 parts of cement, microcapsule phase change 3 parts of materials, 1 part of acetic acid snow melting agent; the nominal maximum particle size of the aggregate is not more than 9.5mm, and the particle size of the mineral powder is less than 0.075mm. The gradation of the micro-surface mixture with snow melting function in this embodiment The type is MS-3, and the specific gradation composition is shown in Table 1;

[0043] In this example, the weight of each component of the microcapsule phase change material is 70 parts of paraffin wax, 8 parts of zinc oxide (heat transfer agent), 7 parts of activated clay (anti-supercooling agent), and polymer water-absorbing resin (anti-phase separation agent) ) 5 parts, 10 parts of melamine-formaldehyde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com