A kind of production method of ethyl vanillin glucoside

A technology of ethyl vanillin and glucoside, which is applied in the field of glycoside preparation, can solve the problems of large amount of catalyst, harsh reaction conditions, expensive catalyst, etc., and achieve the effect of easy-to-obtain raw materials, simple preparation process and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

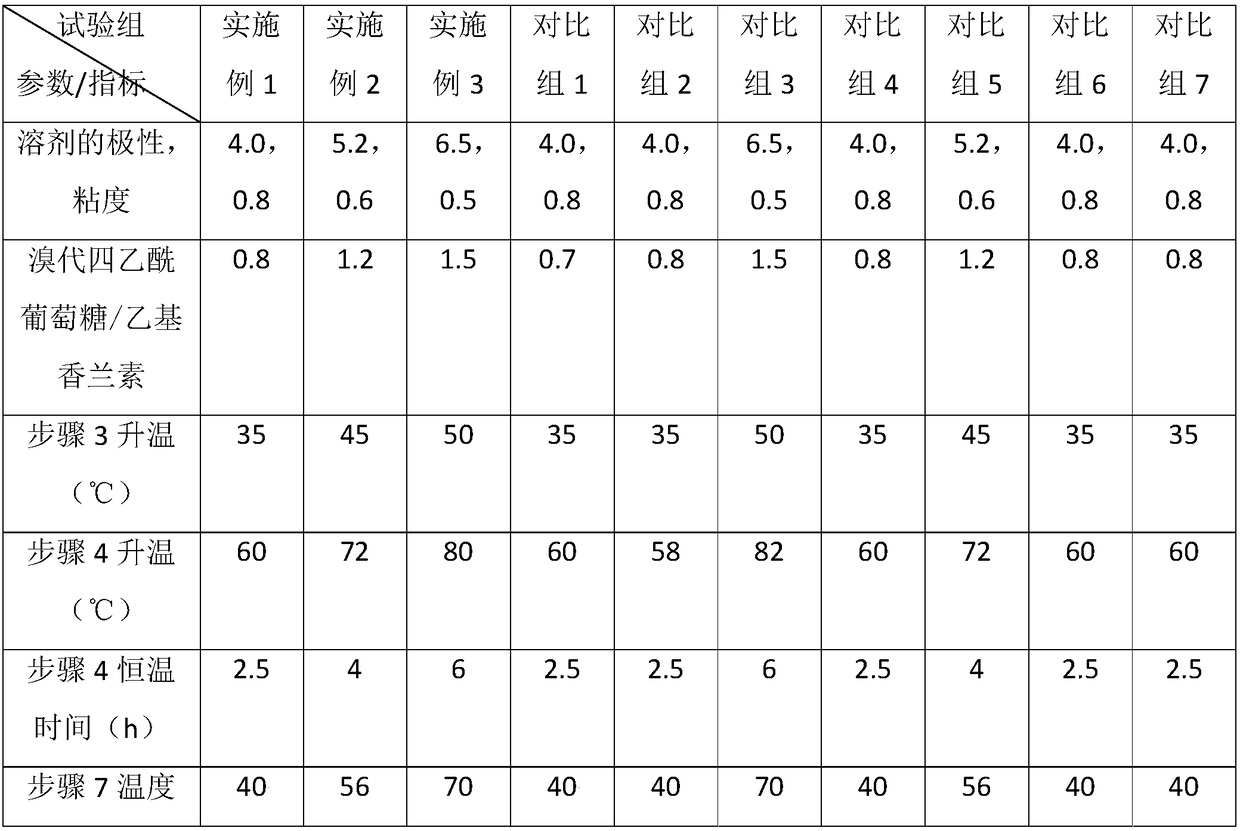

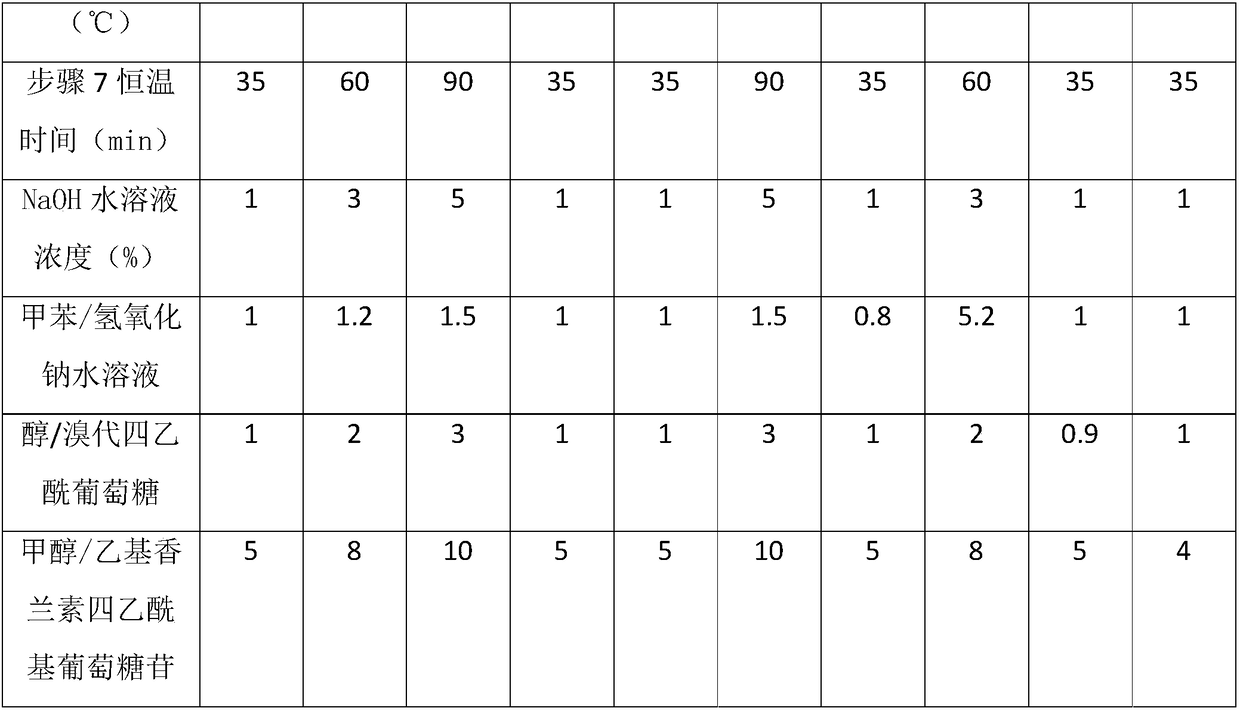

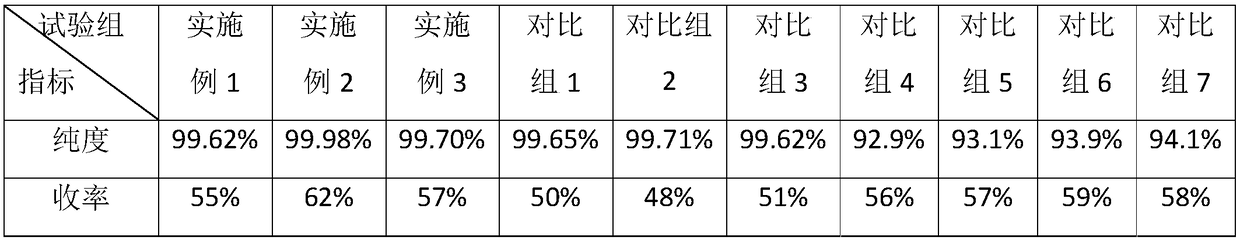

Examples

Embodiment 1

[0039] The present embodiment provides a kind of production method of ethyl vanillin glucoside, comprising the following production steps:

[0040] (1) Add a medium polar organic solvent in the reaction kettle and stir, the polarity of the medium polar organic solvent is 4.0, and the viscosity is 0.8;

[0041] (2) add bromotetraacetylglucose and ethyl vanillin in the reactor, the weight ratio of the bromotetraacetylglucose and ethylvanillin is 0.8;

[0042] (3) be heated up to between 35 ℃, then add basic catalyst;

[0043] (4) Continue to heat up to 60°C for reaction, keep the temperature constant for 2.5h;

[0044] (5) After the reaction finishes, remove the basic catalyst by filtration;

[0045] (6) the polar organic solvent in the filtration mother liquor is reclaimed by distillation;

[0046] (7) Using toluene and sodium hydroxide aqueous solution to carry out reflux treatment at 40 ° C, and keep the temperature for 30 minutes; the concentration of sodium hydroxide aqu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| polarity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com