Snow blower of skip steer loader

A skid steer loader and snow blower technology, which is used in snow surface cleaning, construction, cleaning methods, etc., can solve the problems of inability to realize throwing and rapid adjustment, and achieve the effects of simple structure, fast switching and improved flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

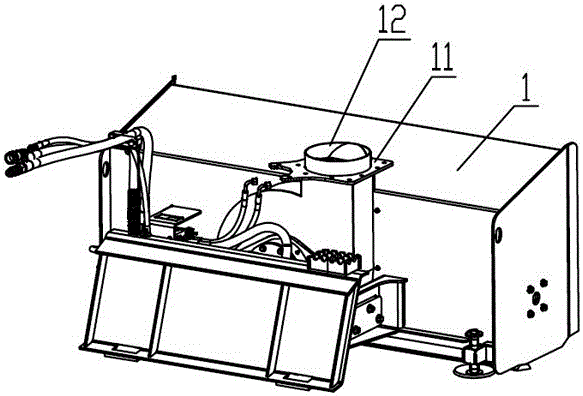

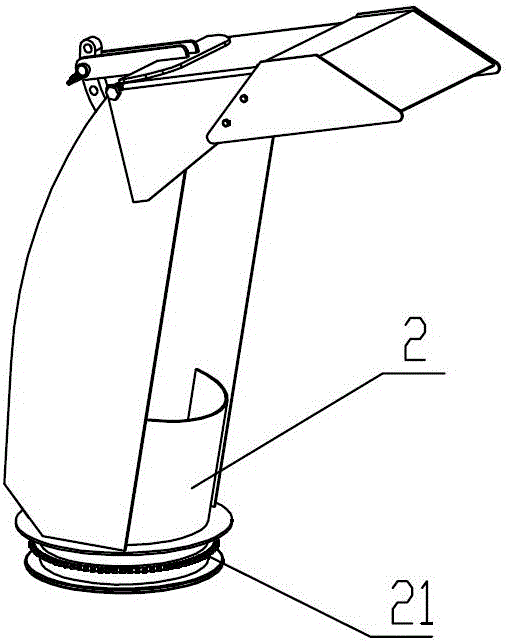

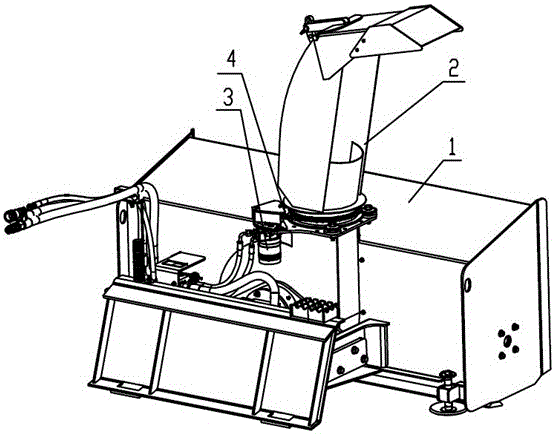

[0020] Such as figure 1 , 2 As shown in and 3, a skid steer loader snow blower includes a snow blower body 1 and a throwing cylinder 2, the middle part of the snow blower body 1 is provided with an installation platform 11, and the middle of the installation platform 11 is provided with an internal guide for the snow blower body 1. Through the installation sleeve 12 that protrudes vertically upwards; the throwing cylinder 2 is set on the outside of the installation sleeve 12 and is detachably connected with the snow blower body 1 through the installation platform 11. The throwing cylinder 2 can be connected with the center of the installation sleeve 12 Rotate to the center. The present invention can rotate the angle of the throwing cylinder 2 as required so as to adjust the snow throwing angle. The bottom of the throwing cylinder 2 is provided with a sprocket 21 , and a motor 3 is installed on the installation platform 11 , and the motor 3 and the sprocket 21 are connected b...

no. 2 example

[0022] Such as Figure 4 with 5 As shown, a snow blower for a skid steer loader includes a snow blower body 1 and a throwing cylinder 2. The middle part of the snow blower body 1 is provided with an installation platform 11, and the middle of the installation platform 11 is provided with a channel that communicates with the inside of the snow blower body 1. The installation sleeve 12 protruding vertically upwards; the throwing cylinder 2 is set on the outside of the installation sleeve 12 and is detachably connected with the snow blower body 1 through the installation platform 11, and the throwing cylinder 2 can be centered on the center of the installation sleeve 12 Make a turn. The present invention can rotate the angle of the throwing cylinder 2 as required so as to adjust the snow throwing angle. The bottom of the throwing cylinder 2 is provided with a sprocket 21 , and a motor 3 is installed on the installation platform 11 , and the motor 3 and the sprocket 21 are conne...

no. 3 example

[0027] Such as Image 6 As shown, a snow blower for a skid steer loader includes a snow blower body 1 and a throwing cylinder 2. The middle part of the snow blower body 1 is provided with an installation platform 11, and the middle of the installation platform 11 is provided with a channel that communicates with the inside of the snow blower body 1. The installation sleeve 12 protruding vertically upwards; the throwing cylinder 2 is set on the outside of the installation sleeve 12 and is detachably connected with the snow blower body 1 through the installation platform 11, and the throwing cylinder 2 can be centered on the center of the installation sleeve 12 Make a turn. The present invention can rotate the angle of the throwing cylinder 2 as required so as to adjust the snow throwing angle. The bottom of the throwing cylinder 2 is provided with a sprocket 21 , and a motor 3 is installed on the installation platform 11 , and the motor 3 and the sprocket 21 are connected by a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com