Construction method of superimposed prefabricated foundation pit structure with reverse frame

A construction method and prefabricated technology, applied in infrastructure engineering, excavation, construction, etc., can solve problems such as difficulty in determining the location of water leakage, hidden dangers of water leakage in cast-in-place walls, and increased cost in construction costs, and achieve simplified construction steps and quality control. And the effect of easy maintenance and short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

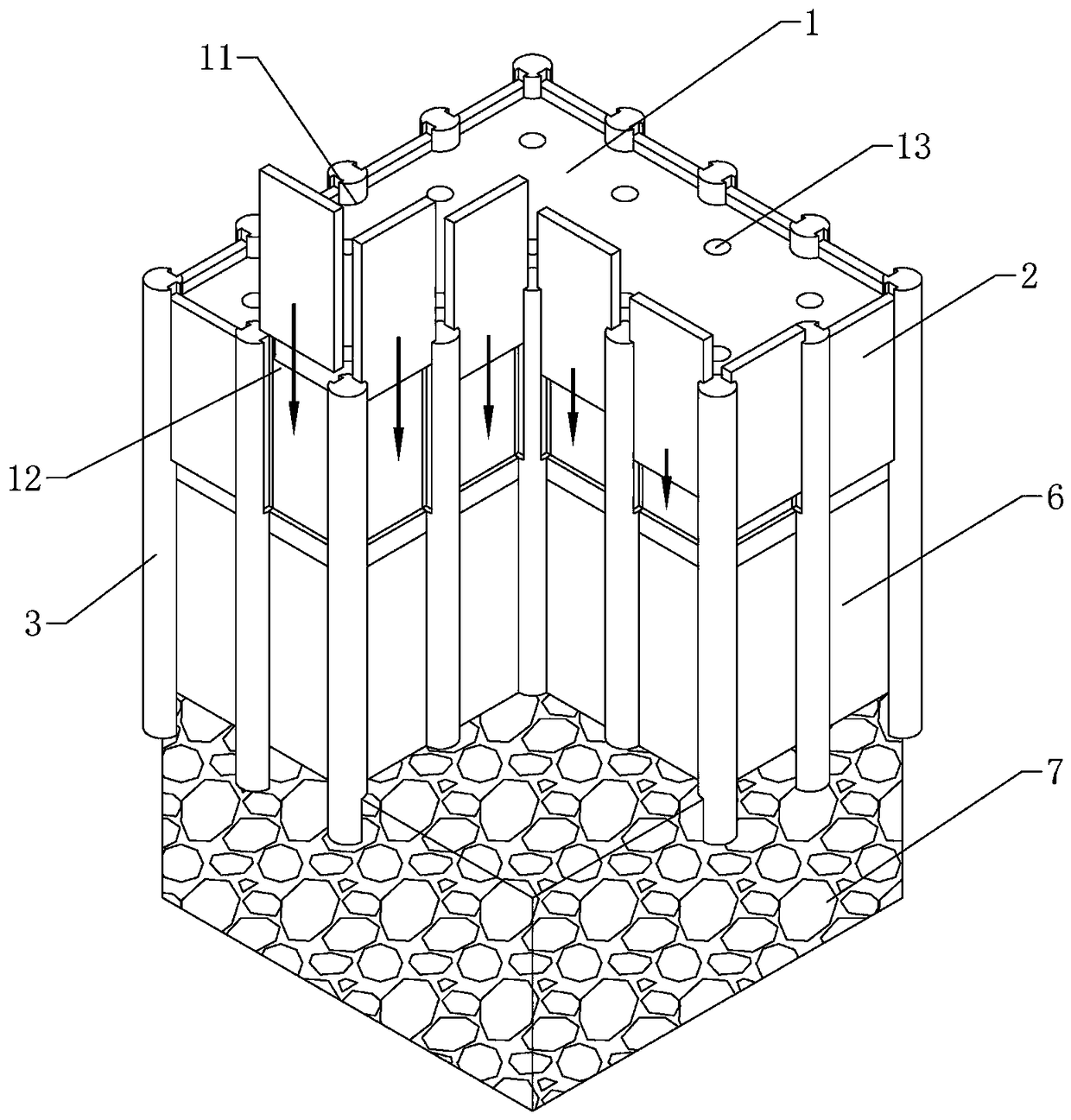

[0043] according to Figure 1 to Figure 6 As shown, the construction method of the superimposed prefabricated foundation pit structure with the frame upside down includes the following steps:

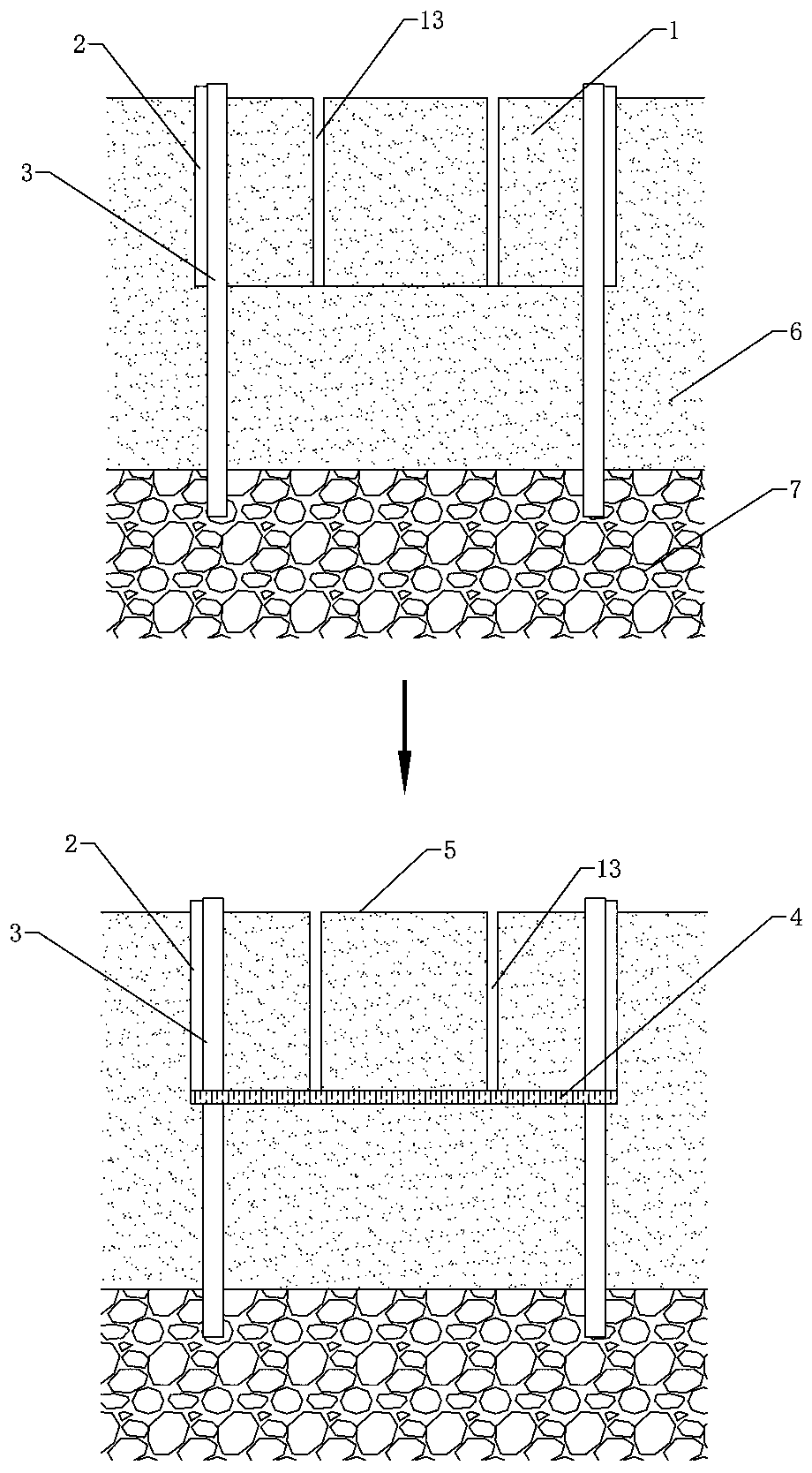

[0044] A. Arrange the foundation pit, design the piling point 11 of the foundation pit 1, and drive the rock-socketed pile 3 at each piling point 11, so that the depth of the pile foundation is greater than the depth of the basement, and the pile penetrates the soft soil layer 6 and drives into the rock layer 7 , forming end piles;

[0045] B, set enclosure, dig guard plate groove 12 between piling points 11 on the edge of foundation pit 1, the depth of guard plate groove 12 matches with the basement 8 depth of design and construction, then pack guard plate 2 in the groove;

[0046] C, bottom grouting, grouting holes 13 are set on the soil surface 5, the depth of the grouting holes 13 matches the depth of the basement, and then grouting in the grouting holes 13, the grouting method ado...

Embodiment 2

[0049] The difference from the above-mentioned embodiment 1 is that in step B, within a certain thickness range above and below the depth position of the continuous enclosure, full-scale cement mixing piles are used for reinforcement, and the reinforcement range exceeds the scope of the foundation pit according to the design requirements, and the maximum does not exceed the planned red line.

Embodiment 3

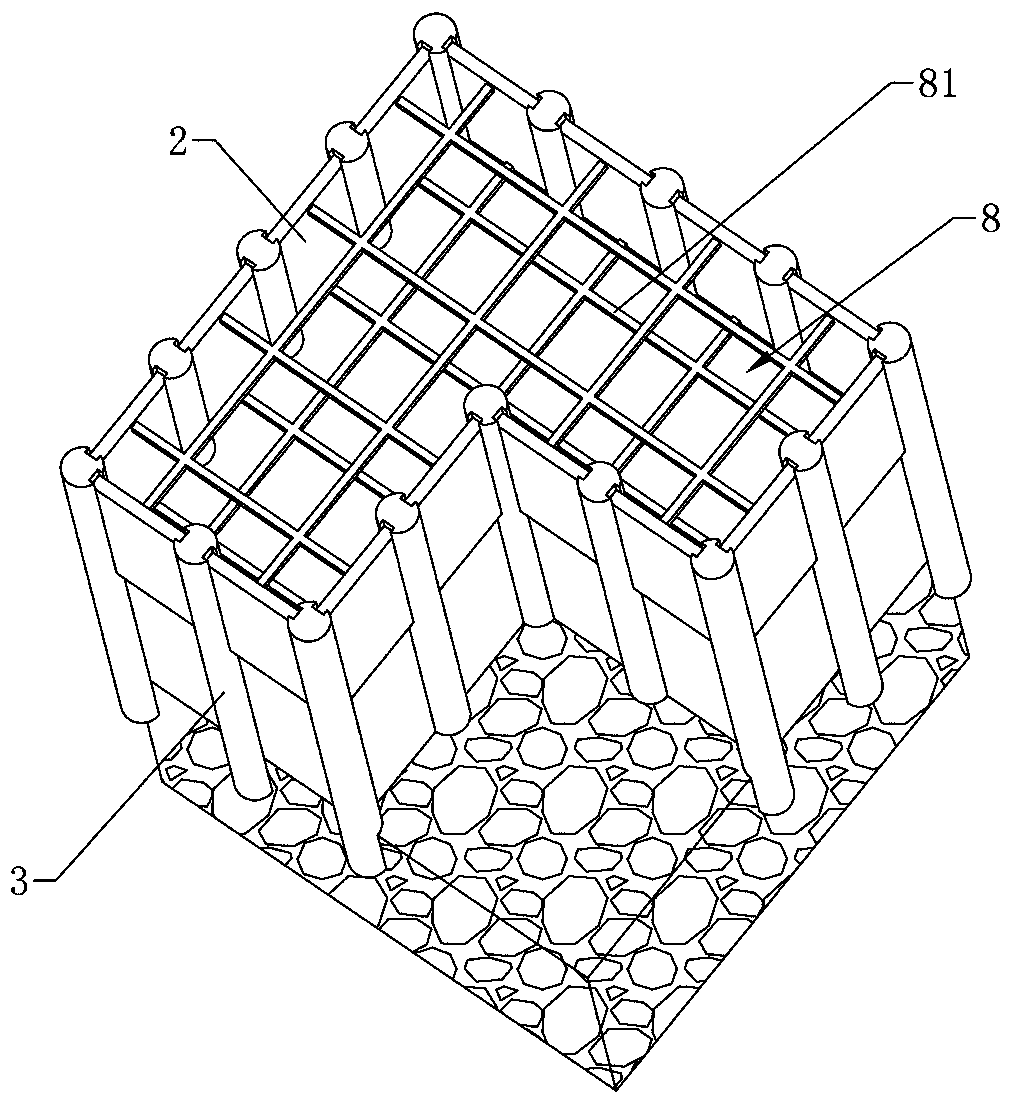

[0051] The difference from Embodiment 1 above is that the support beam 81 adopts the composite beam technology, that is, the prefabricated beam is assembled in sections, and the prefabricated part is connected with the profiled steel plate; the floor slab is integrated with the support beam 81 after being combined with the profiled steel plate , the supporting beam 81 is reserved with an assembly interface with the profiled steel composite floor. The advantage of the profiled steel plate is that the bottom does not need to be supported, and it is light in weight and high in strength. After being connected with the beam, the concrete is then poured to form a beam-slab system. The support of the floor slab is an underground structural column; the method of hoisting the profiled steel plate 82 is: First, stack and hang the profiled steel plates required underground on the corresponding steel columns, use the sliding form device installed on the steel columns to excavate a layer, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com