A formwork support for cast-in-place concrete slabs

A concrete slab and formwork support technology, which is applied in the field preparation of formwork/formwork/work frame, building components, construction, etc., can solve the problems of lack of economic significance of formwork, low artificial efficiency, and fine construction management restrictions and other problems, to achieve the effect of project quality and economic benefits, save the amount of component materials, and save labor hours.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

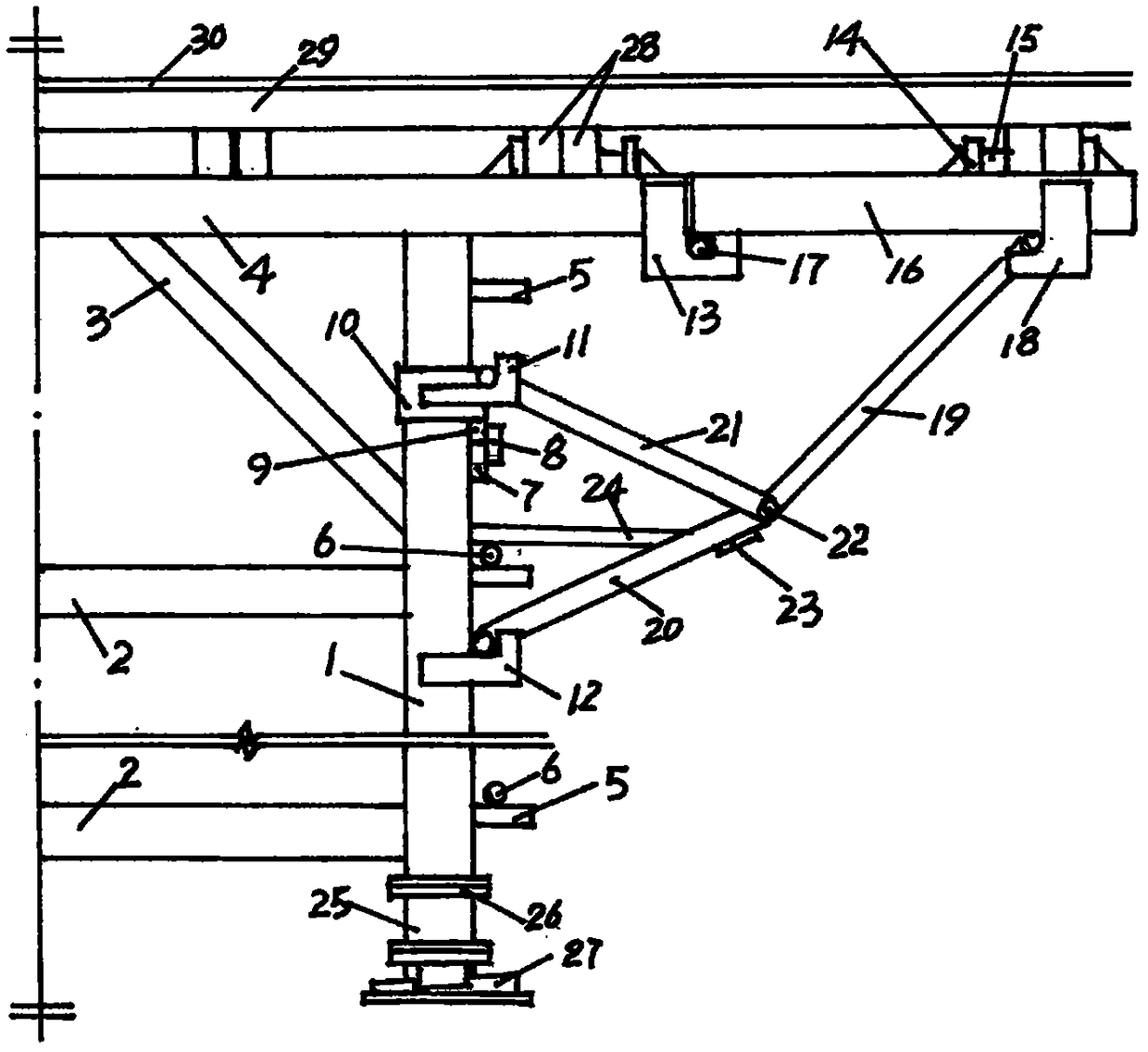

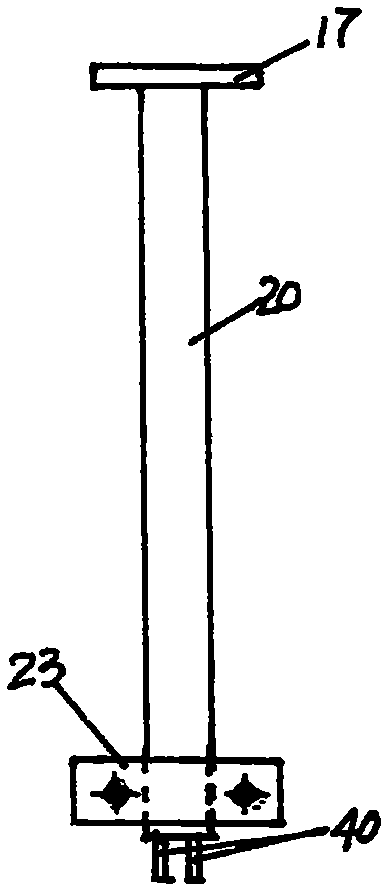

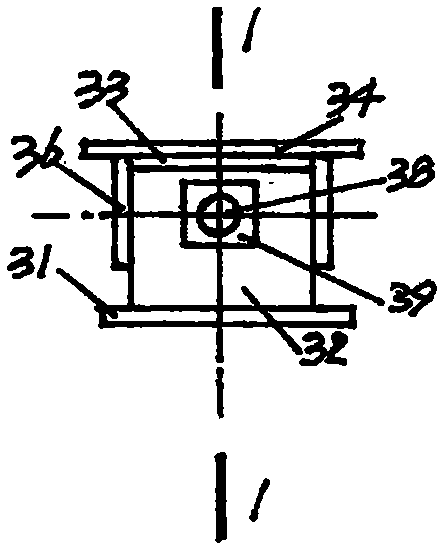

[0024] Complete the flange connection between the limb column 1 and the long joint 25 and the frame seat 27 before the formwork is supported. Perpendicularity, connecting the connecting rod joint 5 with the longitudinal connecting rod 6 and the diagonal brace with fasteners, the large corrugated 28 is overlapped in the clamping seat 14 at both ends of the top beam 4, and the wedge 15 wedges the clamping seat 14 and the large corrugated 28; The fixed hinge shaft 17 of the beam external joint 16 is hung on the half hinge groove 13 of the top beam 4, the fixed hinge shaft 17 of the upper strut 19 is supported on the half hinge groove 18 of the top beam external joint, and the fixing of the lower strut 20 The hinge shaft 17 is inserted into the half-hinge groove 12 of the limb column, and the fixed hinge shaft 17 of the pull rod 21 is hung on the half-hinge groove 11 of the sleeve. The horizontal direct pin of bar 24 is inserted into the pin hole of lateral connecting plate 23, co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com