Flow-in control valve

A technology for inflow control valves and spools, applied in the direction of wellbore/well valve devices, wellbore/well parts, sealing/packing, etc., can solve the problems of poor oil quality and low production, and prevent water formation and gas layer penetration, increasing oil inflow, controlling production and quality effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

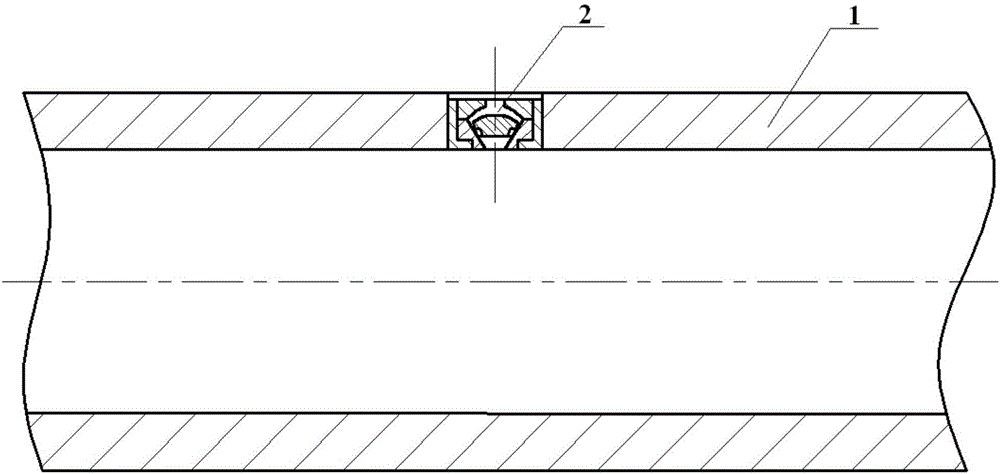

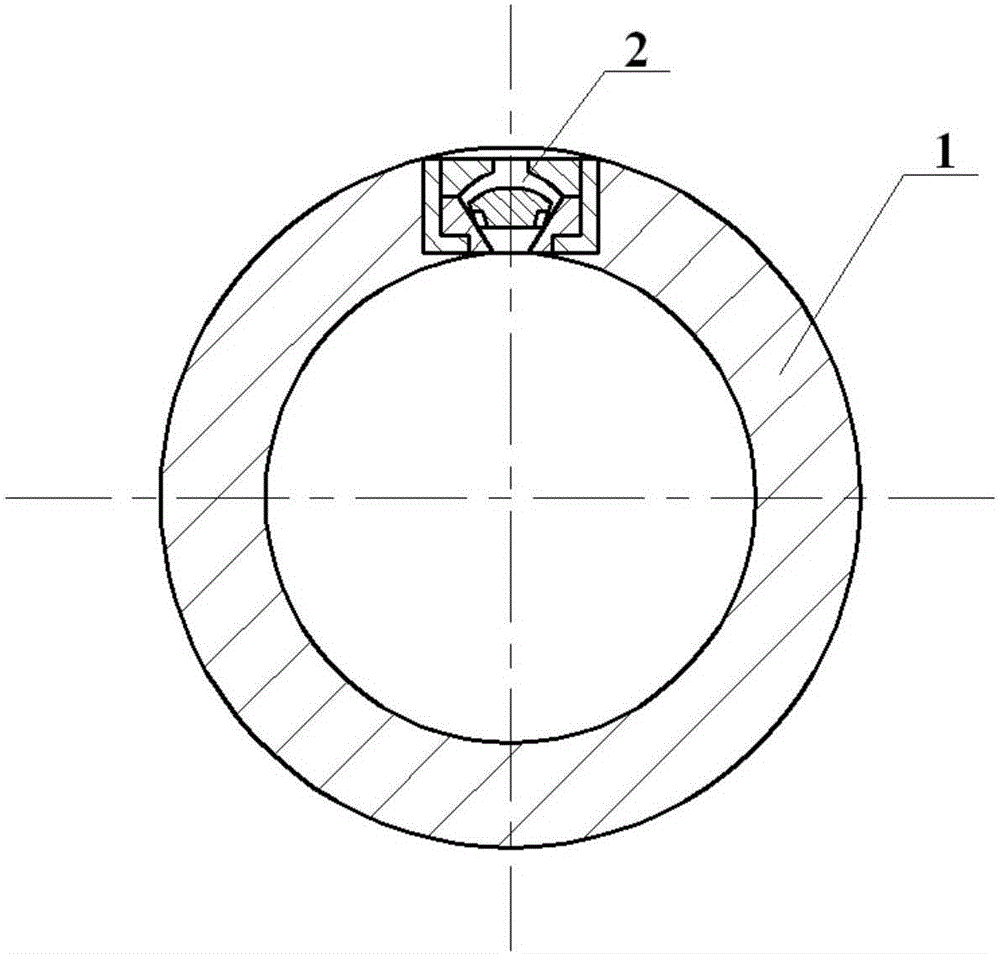

[0021] figure 1 , figure 2 A cross-sectional view of a production pipeline provided with an inflow control valve of the present invention is shown. The production pipeline 1 has a round hole, and the valve 2 is installed on the production pipeline 1 by threaded connection or expansion joint. The height of the valve 2 can vary with the thickness of the production pipeline 1. The arrangement of the valve 2 on the production pipeline 1 It can be adjusted according to different production conditions.

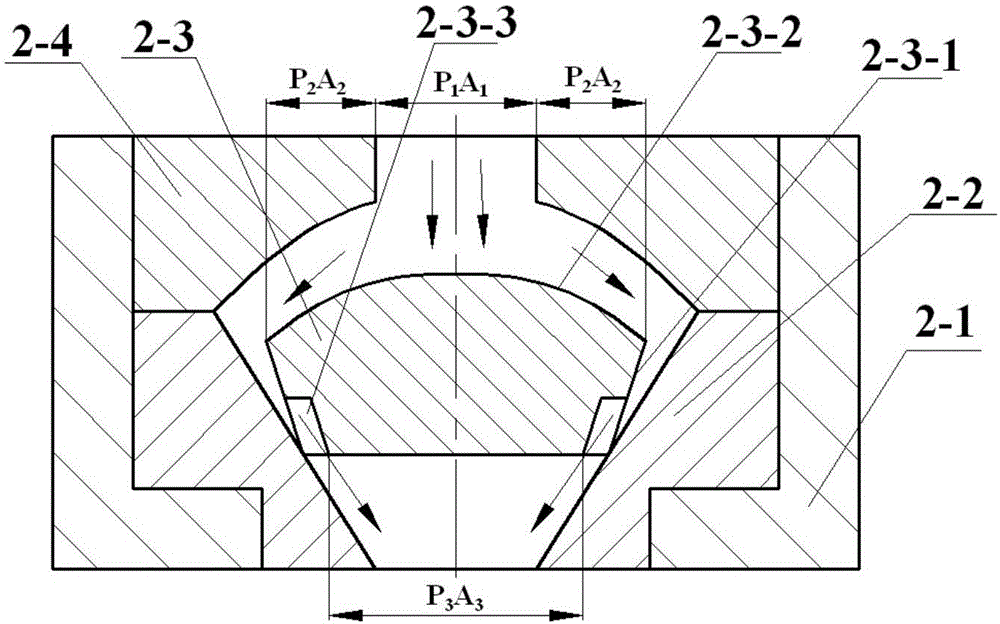

[0022] image 3 The structure of an inflow control valve of the present invention is shown. This control valve is made up of valve seat 2-1, lower valve body 2-2, spool 2-3, upper valve body 2-4. The valve seat 2-1 is installed on the production pipeline 1, and there is a stepped hole inside; the lower valve body 2-2 is embedded in the stepped hole of the valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com