A sealing device for a micro rotor engine

A rotary engine and sealing device technology, which is applied to the sealing device of the engine, the engine components, the machine/engine, etc., can solve the problems of complex structure and easy failure of the sealing device for the rotary engine, so as to improve the power and life, work reliably, Improve the effect of partial wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

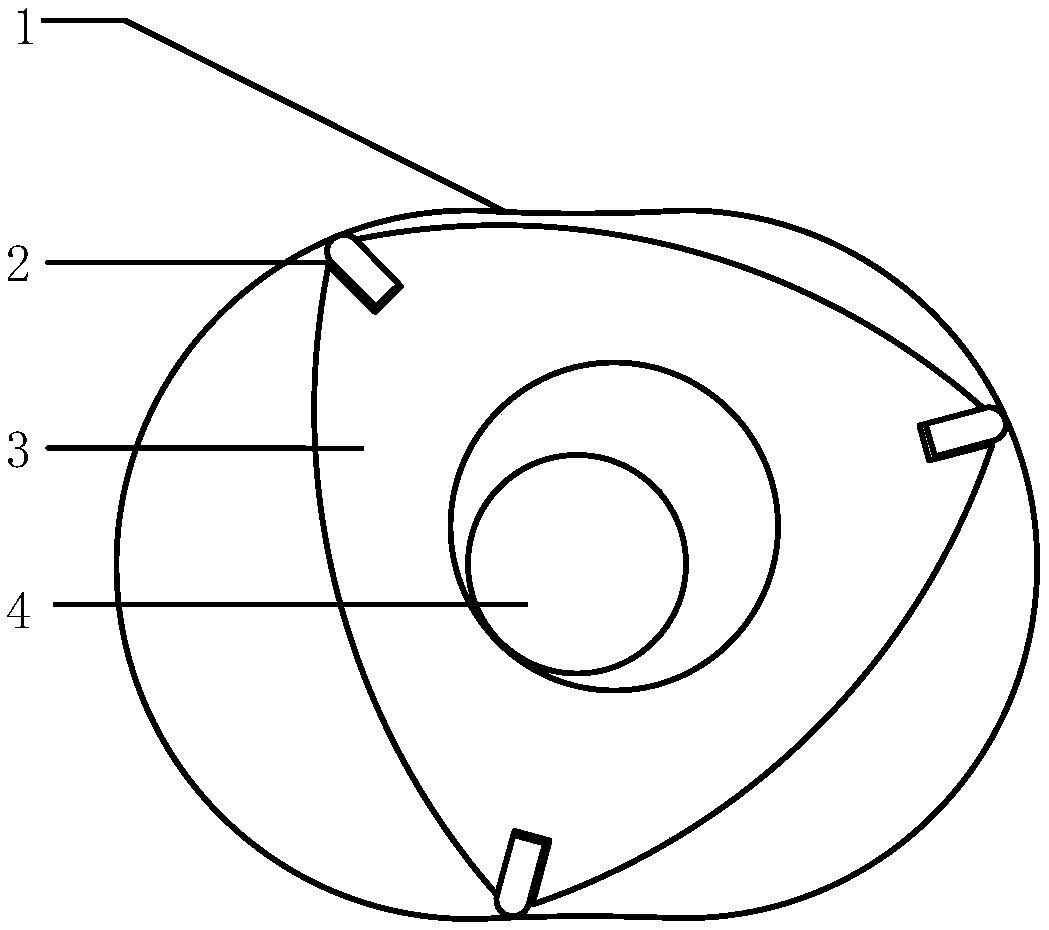

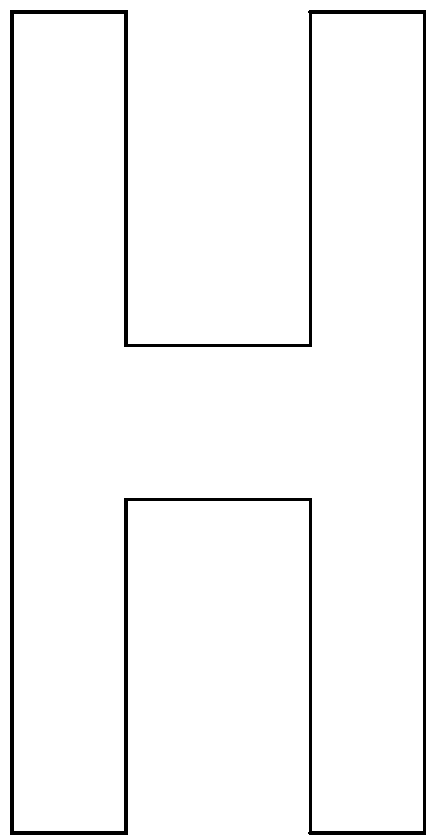

[0027] This embodiment discloses a sealing device for a micro-rotary engine, such as figure 1 shown. Taking a 5CC rotor engine with a radius of 21mm, an eccentricity of 3mm and a thickness of 14.5mm as an example, the sealing sheet 2 and the spring sheet 5 are installed in the sealing groove on the rotor. figure 2 and image 3 Respectively, the front view and the left view of the leaf spring. Figure 4 , Figure 5 and Figure 6 It is a top view, a front view and a rear view of the sealing sheet 2. The sealing sheet 2 and the spring sheet 5 are installed in the sealing groove on the rotor, wherein the arc portion of the top of the sealing sheet 2 is in contact with the cylinder 1 . The spring piece 5 is installed on the spring piece on the back of the sealing piece 2, and its arc top is in contact with the bottom of the sealing groove. The two bosses on the back of the sealing piece 2 can prevent the movement of the spring piece 5 and have a certain pre-tightening force. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com