Bearing assembly

一种轴承、轴承腔的技术,应用在轴承元件、轴承、球轴承等方向,能够解决不能保证轴承绝对密封等问题,达到提高效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

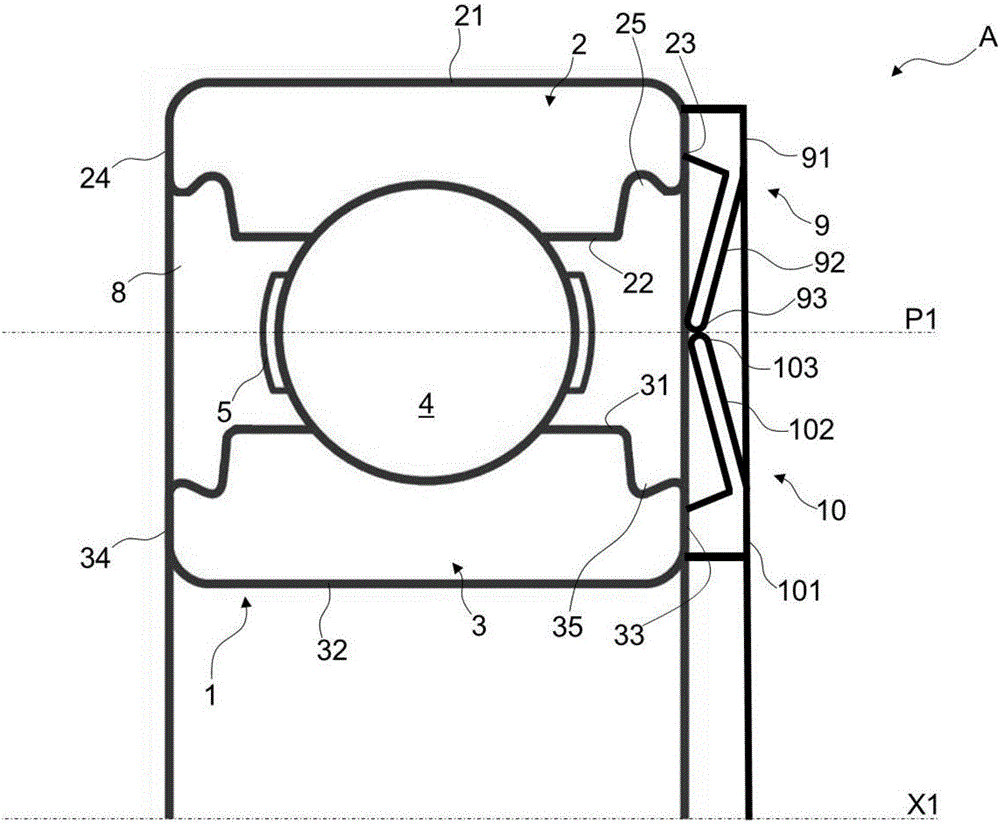

[0050] Unit A comprises a bearing 1 with a central axis X1 provided with an outer ring 2 , an inner ring 3 , a row of rolling bodies 4 (in this case, balls). The rolling bodies are arranged in parallel planes and are each held by cages 5 . This unit is designed to be installed in a housing provided in the mechanical system (not shown).

[0051] In normal operation mode, the outer ring 2 and the inner ring 3 are coaxial with the central axis X 1 .

[0052] The outer ring 2 has a cylindrical outer surface 21 and a bore 22 in which a raceway for the rolling elements 4 is formed.

[0053] The inner ring 3 has a cylindrical outer surface 31 in which raceways for the rolling elements 4 are formed.

[0054]The inner ring 3 may be rotating and the outer ring 2 non-rotating, or vice versa, or the two inner and outer rings may be rotatable relative to each other.

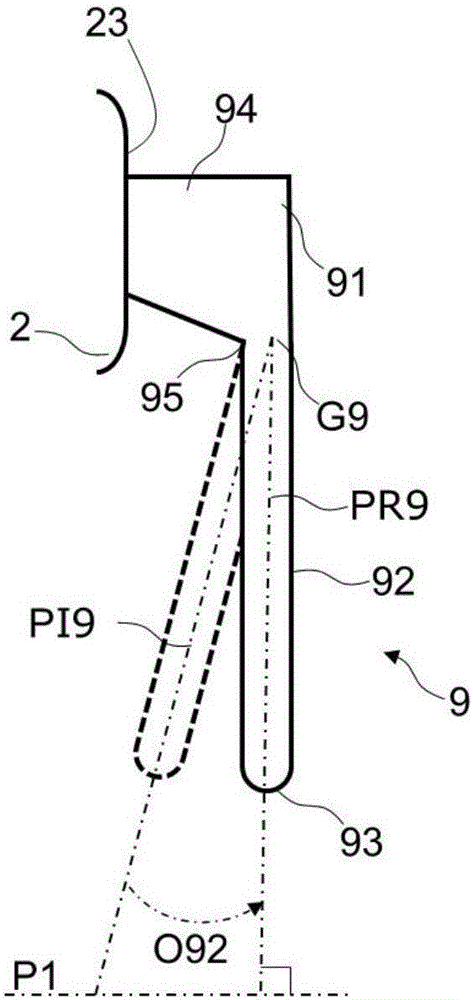

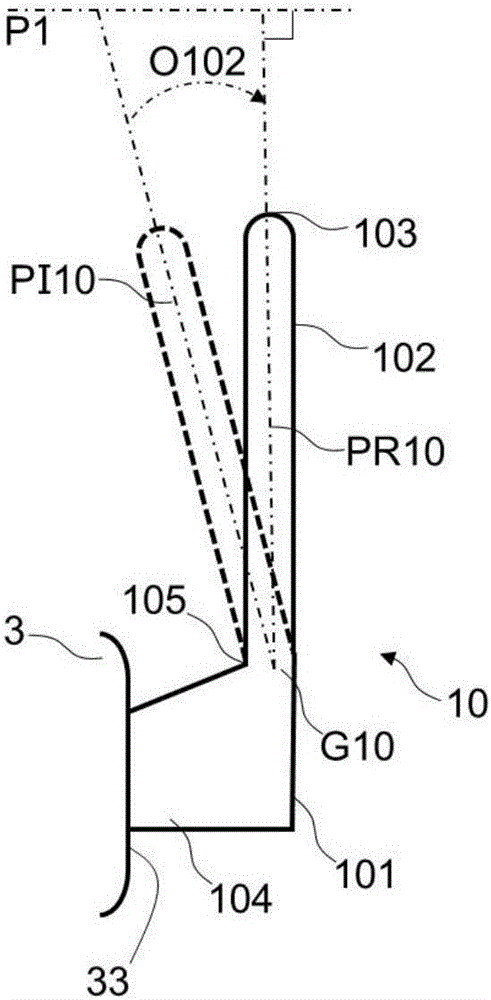

[0055] The outer ring 2 is axially bounded by two radial side edges 23 and 24 and the inner ring 3 is axially bounded by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com