Double-row spherical roller bearing double-lip sealing structure and wind driven generator

A spherical roller, sealing structure technology, applied in the direction of bearing components, shafts and bearings, mechanical equipment, etc., can solve the problems of leakage, sealing structure sealing failure, etc., to improve the sealing effect, improve the anti-eccentric ability, good follow-up Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

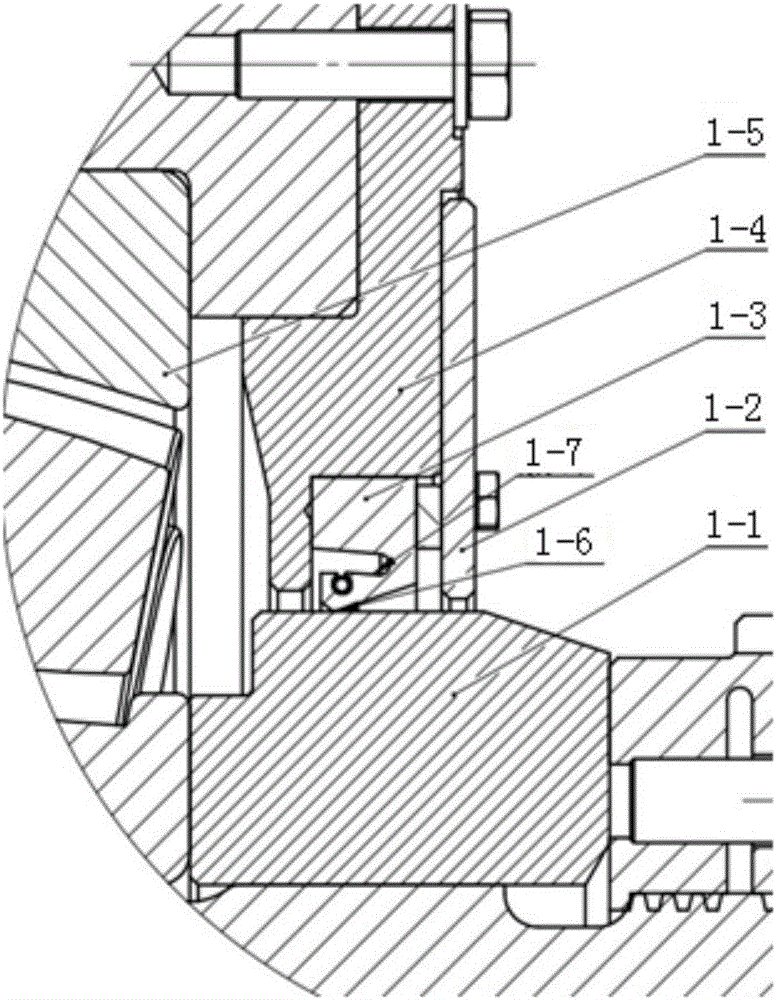

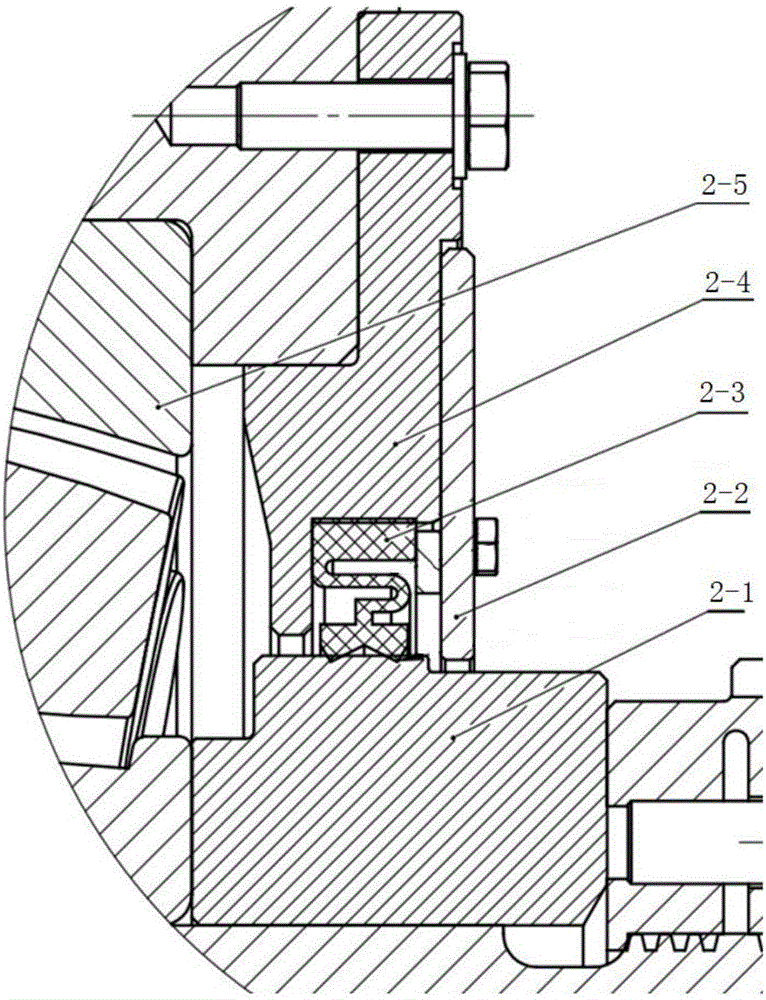

[0028] Embodiment 1: A double-row spherical roller bearing double-lip seal structure, its structure is as follows figure 2 and image 3 As shown, it includes the inner sealing ring 2-1, the upper part of the sealing ring 2-1 is the pressure plate 2-2, the inner side of the pressure plate 2-2 is the sealing ring 2-3, the bearing end cover 2-4 and the double row spherical roller bearing body 2 -5;

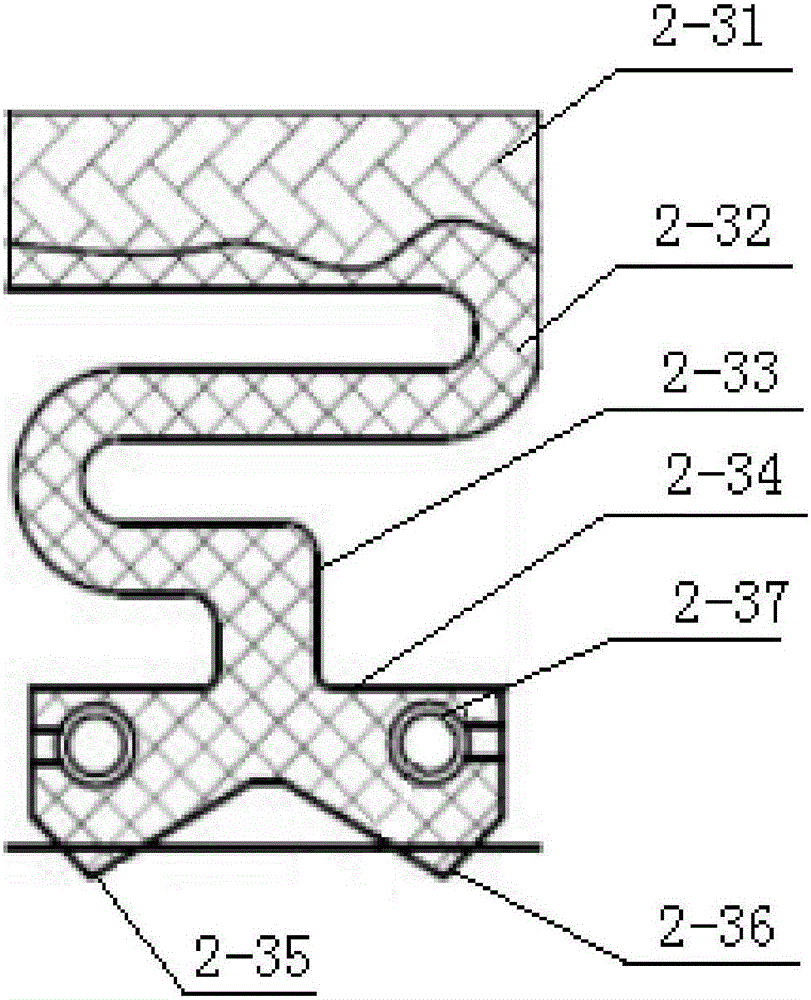

[0029] The bearing end cover 2-4 is located above the sealing ring 2-3. Wherein, the sealing ring 2-3 includes an integrally formed sealing ring top 2-31, the sealing ring top 2-31 is connected to one end of the bent waist 2-32, and the other end of the bent waist 2-32 is connected to the vertical transition portion 2 -33 is airtightly connected, and the vertical transition part 2-33 is connected with the bottom 2-34 of the sealing ring;

[0030] The lower surface of the sealing ring bottom 2-34 has a first sealing lip 2-35 and a second sealing lip 2-36.

[0031] At the same tim...

Embodiment 2

[0035] Embodiment 2: A wind power generator, the wind power generator has a main shaft, and the main shaft is assembled with a bearing housing by means of a double-row spherical roller bearing, wherein the double-row spherical roller bearing has the Double lip seal construction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com