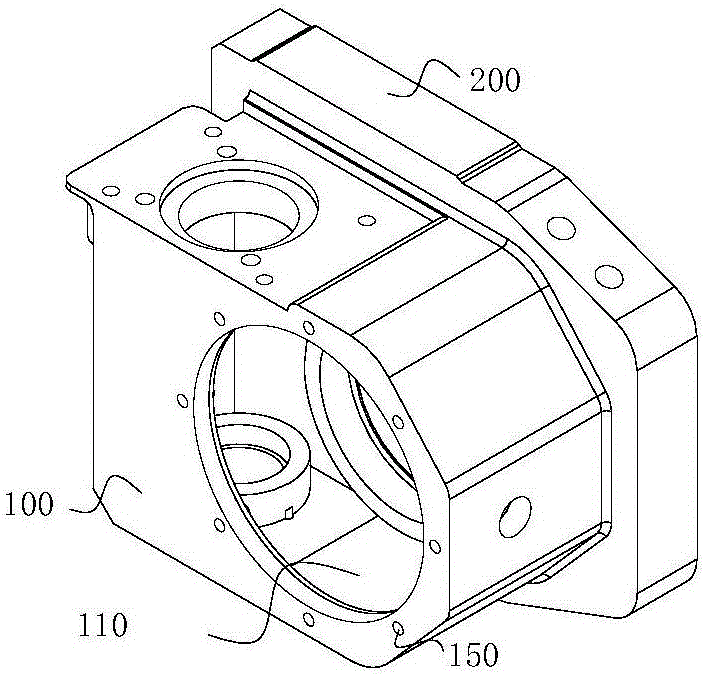

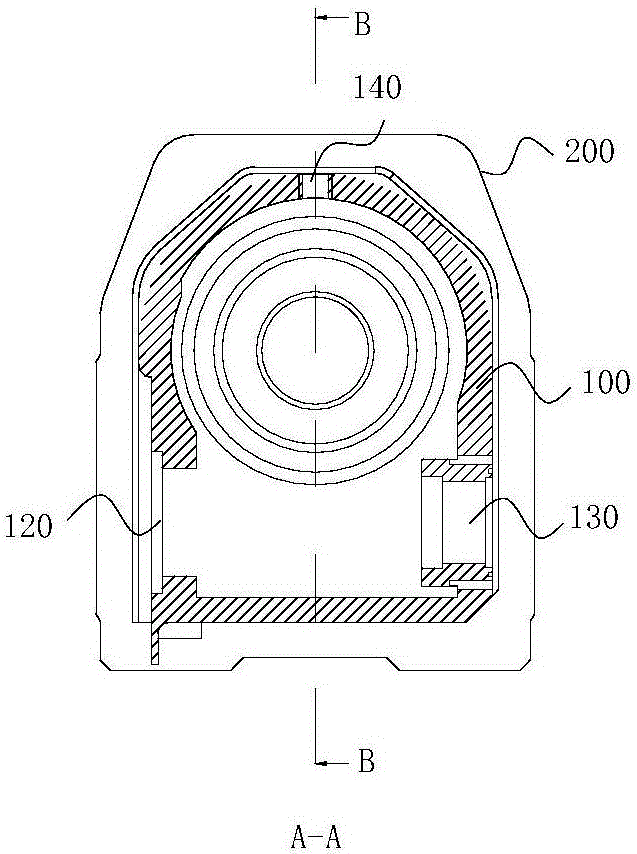

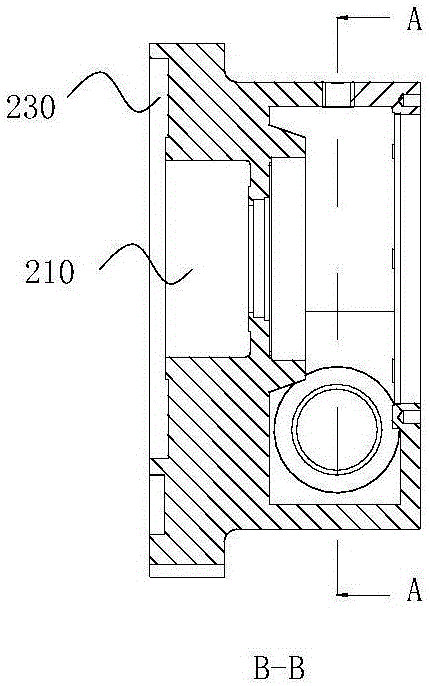

Gearbox aluminum casting fixing base

A fixed seat and box aluminum technology, applied in the direction of belts/chains/gears, transmission parts, mechanical equipment, etc., can solve problems such as loss of transmission efficiency, relative sliding and offset, easily damaged gears, etc., to achieve stable fixed gears , strong wear resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] S1: Preheat the melting furnace to 200°C;

[0054] S2: Raw materials for configuring the composition, by mass percentage: Si1%, Fe0.1%, Mn0.2%, Cu2%, Mg2%, Zn6%, Ce0.1%, Y0.05%, the balance is aluminum , after mixing the raw materials evenly, put them into the smelting furnace and raise the temperature to 700°C to completely melt into a molten liquid, in which the raw material aluminum is added in 3 times;

[0055] S3: Add a mixture of Al2O3, TiC and SiC whiskers to the melt, the aspect ratio of the whisker mixture is 15:1, wherein the length of the Al2O3 whiskers is 6 μm, and the length of the TiC and SiC whiskers The length is 5 μm, adding a mass percentage of 0.5% refining agent, the refining agent is a mixture of 70% by mass of hexachloroethane, 10% of sodium fluorosilicate, and 20% of carnallite, after degassing and refining Stand still for 10 minutes after 20min, in the refining process, feed the mixed gas of nitrogen and carbon tetrachloride from the bottom of t...

Embodiment 2

[0057] S1: Preheat the melting furnace to 300°C;

[0058] S2: Raw materials for configuring the above-mentioned components, by mass percentage: Si1.5%, Fe0.2%, Mn0.3%, Cu1%, Mg3%, Zn8%, Ce0.2%, Y0.1%, balance For aluminum, after mixing the raw materials evenly, put them into the smelting furnace and raise the temperature to 680°C to completely melt into a molten liquid, in which the raw material aluminum is added in 5 times respectively;

[0059] S3: Add a mixture of Al2O3, TiC and SiC whiskers to the melt, the aspect ratio of the whisker mixture is 18:1, wherein the length of the Al2O3 whiskers is 10 μm, and the length of the TiC and SiC whiskers The length is 4 μm, adding a mass percentage of 0.7% refining agent, the refining agent is a mixture of 70% by mass of hexachloroethane, 20% of sodium fluorosilicate, and 10% of carnallite, after degassing and refining Stand still for 10 minutes after 20min, in the refining process, feed the mixed gas of nitrogen and carbon tetrachl...

Embodiment 3

[0061] S1: Preheat the melting furnace to 250°C;

[0062] S2: Raw materials for the configuration of the composition, by mass percentage: Si1.5%, Fe0.15%, Mn0.3%, Cu1%, Mg3%, Zn10%, Ce0.1%, Y0.1%, the balance For aluminum, after mixing the raw materials evenly, put them into the smelting furnace and raise the temperature to 690°C to completely melt into a molten liquid, in which the raw material aluminum is added in 4 times respectively;

[0063] S3: Add a mixture of Al2O3, TiC and SiC whiskers to the melt, the aspect ratio of the whisker mixture is 15-18:1, wherein the length of the Al2O3 whiskers is 7 μm, and the TiC and SiC whiskers The length of the whiskers is 4 μm, adding a mass percentage of 0.5 to 0.8% refining agent, the refining agent is a mixture of 60% hexachloroethane, 20% sodium fluorosilicate, and 20% carnallite, After degassing and refining for 15 minutes, let it stand for 10 minutes. During the refining process, a mixed gas of nitrogen and carbon tetrachlorid...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap