Rapid cooling device for printing workshop

A technology for printing workshops and cooling devices, applied in space heating and ventilation, household heating, lighting and heating equipment, etc., can solve problems such as large power consumption, rising costs, and poor cooling effect of external methods, and achieve savings Power cost, effect of load reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

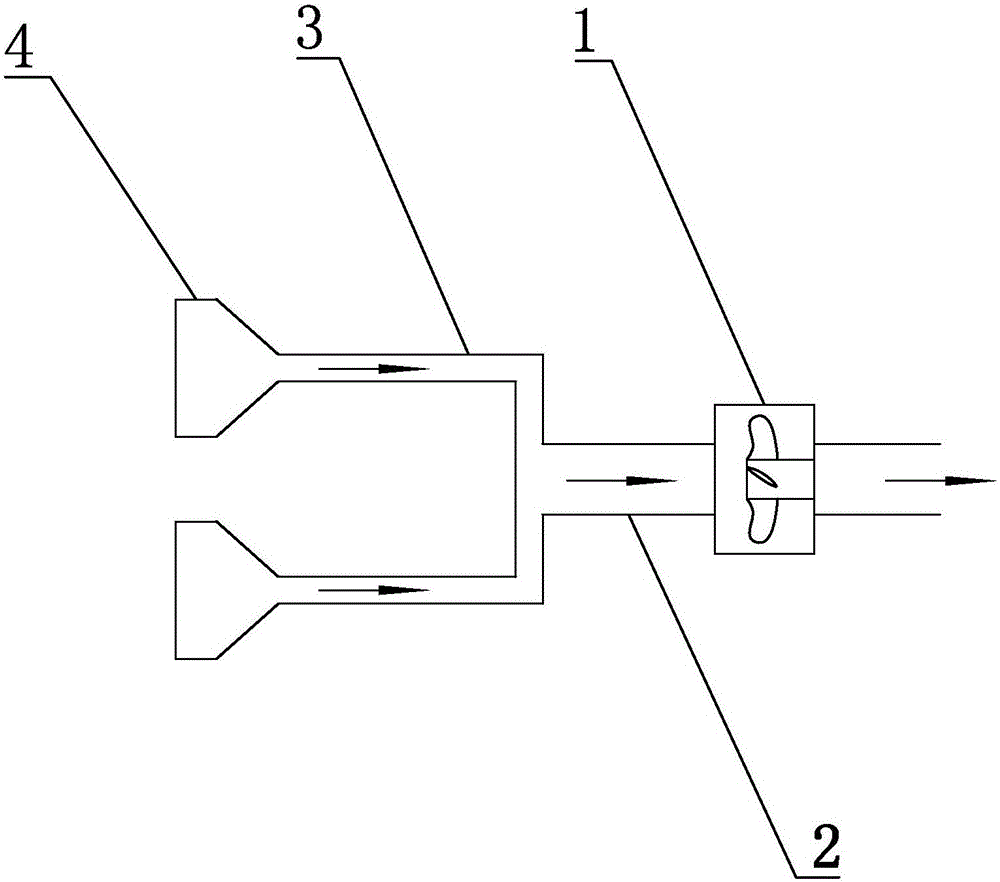

[0010] refer to figure 1 , a rapid cooling device for a printing workshop, which includes a plurality of collection covers 1, a wide-mouthed collection cover 4, the collection cover 4 faces and covers the heat dissipation port of the main heating equipment in the printing workshop, and each of the collection covers 4 is equipped with Branch pipe 3, several branch pipes 3 are connected to the exhaust pipe 2, the waste heat air enters the branch pipe 3 through the collection cover 4, and then gathers to the exhaust pipe 2, the exhaust pipe 2 is equipped with a negative pressure fan 1, a negative pressure fan 1 High ventilation efficiency, the cooling and ventilation effect can reach 90%-97%, especially suitable for lowering the room temperature. The diameter of the branch pipe 3 is smaller than the diameter of the exhaust pipe 2, and as a branch pipe, a smaller diameter is beneficial to improve the absorption rate.

[0011] The negative pressure fan 1 sucks the waste heat air e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap