Defrosting control system

A control system and filter technology, used in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of liquid refrigerant higher than the storage temperature, compressor damage, compressor oil throwing wear and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

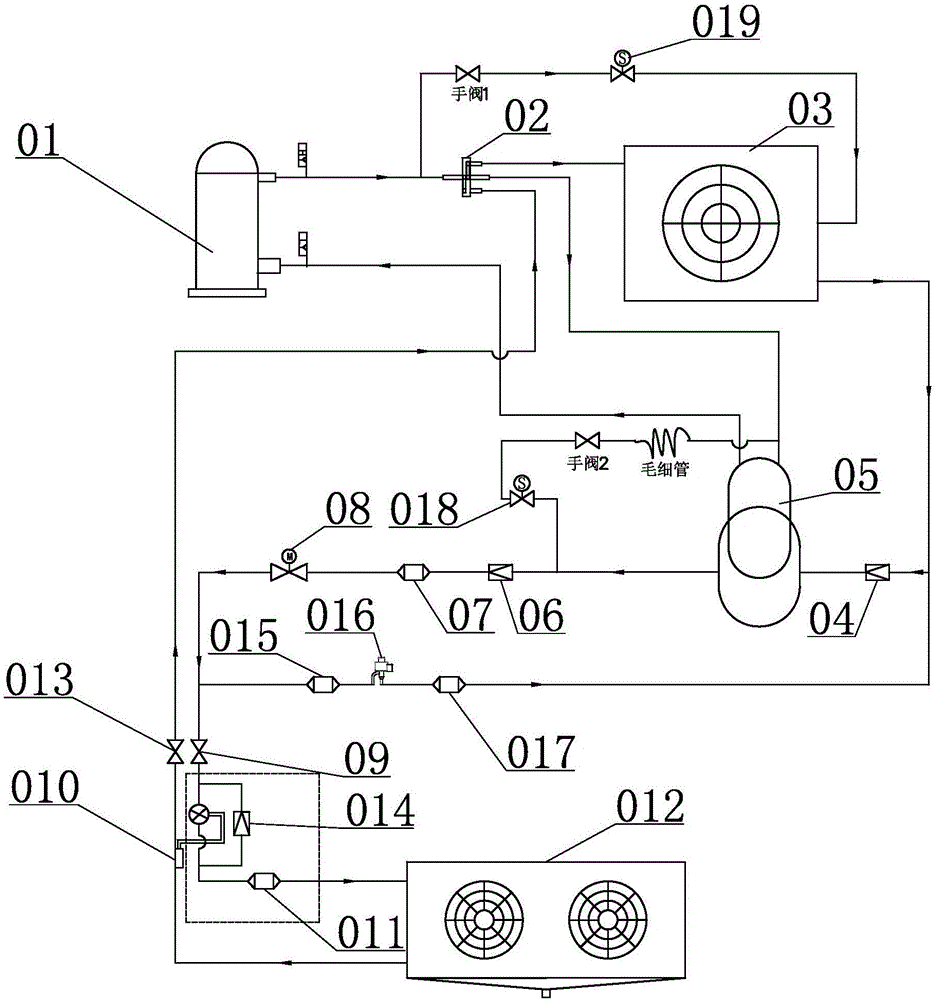

[0018] Below in conjunction with accompanying drawing, invention is described in further detail.

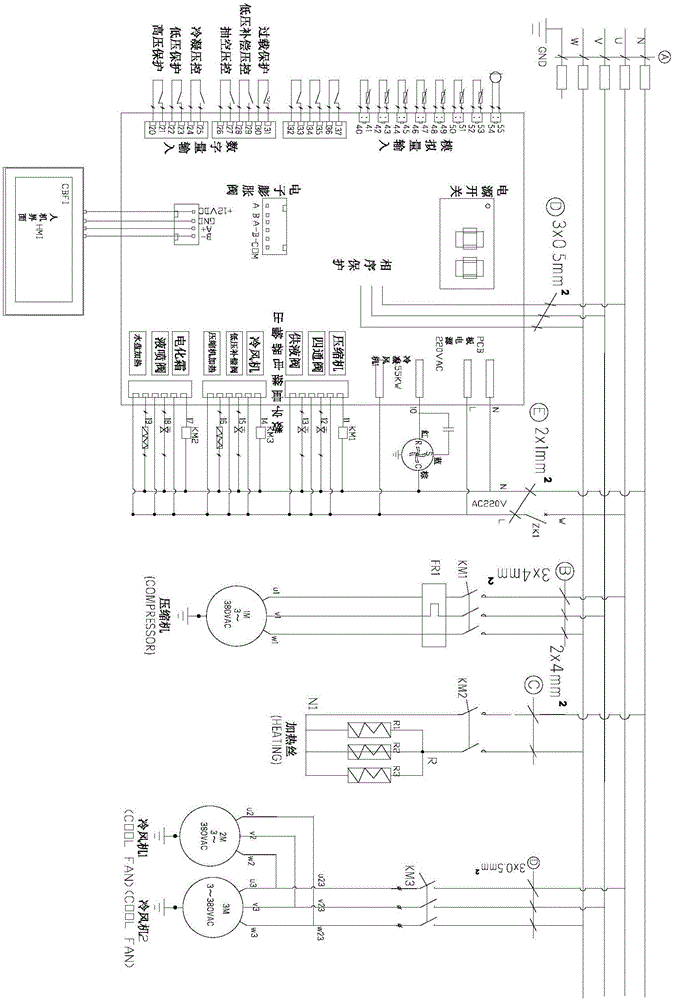

[0019] Such as Figure 1-2As shown, a defrosting control system includes a compressor 01, a four-way valve 02 communicated with the compressor 01, a condenser 03 communicated with the four-way valve 02, a first one-way valve 04 communicated with the condenser 03, The gas-liquid separator 05 communicated with the first one-way valve 04 and the compressor 01, the second one-way valve 06 communicated with the gas-liquid separator 05, the first filter 07 communicated with the second one-way valve 06, The electromagnetic valve 08 communicated with the first filter 07, the first threaded interface 09 communicated with the electromagnetic valve 08, the thermal expansion valve 010 communicated with the first threaded interface 09, the second filter 011 communicated with the thermal expansion valve 010, The air cooler 012 communicated with the second filter 011, the second threaded inter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com