High temperature radial loading stress corrosion sample device

A technology of stress corrosion and test equipment, applied in the direction of applying stable tension/pressure to test material strength, test wear resistance, etc., can solve problems such as solution leakage, achieve constant concentration, avoid heat dissipation, and reduce water vapor evaporation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

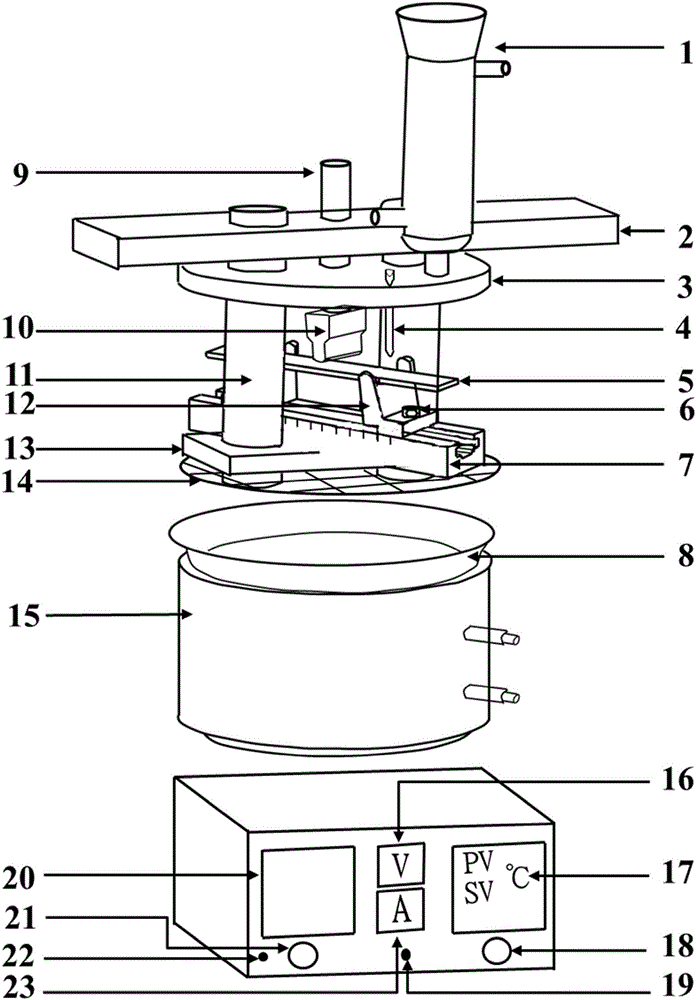

[0028] Such as figure 1 As shown, the high temperature radial loading stress corrosion test device of this embodiment mainly includes a load application system, a temperature control system and other structural components. Force frame, a drop-proof filter screen 14, a beaker 8, a stainless steel heating ring 15, a thermocouple 4 sealed with polytetrafluoroethylene, a temperature controller 17, a condensate return pipe 1 and a rubber Plug 3, the guide rail loading bracket device with scale is made up of guide rail 7 with scale, fastening nut 6, a pair of guide rail supports 12, and the reverse force frame is composed of the upper beam 2 of the reverse force frame, the lower beam 13 of the reverse force frame and Reverse force frame column 11 forms. Wherein, the upper beam 2 of the reverse force frame is fixed on two columns of the constant load testing machine, and the guide rail 7 with scale is fixed on the lower beam 13 of the reverse force frame, and the guide rail 7 with s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com