Coal oxidation characteristic testing device based on coal and gas cogeneration and testing method thereof

A characteristic test and coal oxidation technology, which is applied in the direction of weighing by removing certain components, can solve problems such as unsuitable research on coal oxidation characteristics, gas is prone to explosion, and researchers are injured, so as to overcome the excessive addition of coal samples. Less, prevent machine damage, simple structure effect

Inactive Publication Date: 2017-02-15

ANHUI UNIV OF SCI & TECH

View PDF14 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] The device used in traditional thermogravimetric analysis is generally an ordinary thermogravimetric analyzer, which can measure the kinetic parameters of coal in the atmosphere of air, nitrogen and carbon dioxide. Explosions are prone to occur u

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

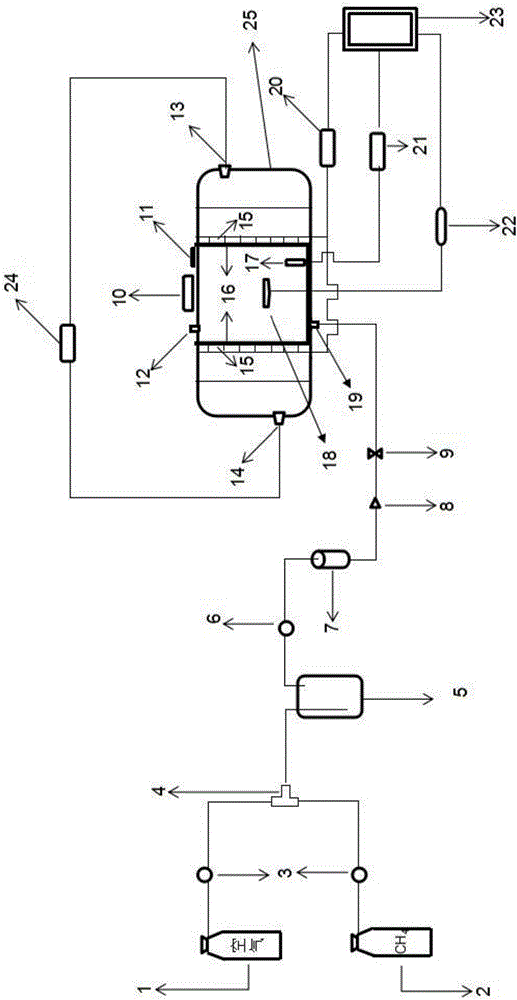

The invention discloses a coal oxidation characteristic testing device based on coal and gas cogeneration and a testing method thereof. The testing device comprises an air source, a methane air source, branched flow meters, a three-way valve, a water seal buffer, a total flow meter, a drier, a one-way air valve, a fire-retardant breather valve and a cavity, wherein an air pipe for communicating the air source and the methane air source is inserted into an air inlet of the cavity; the middle part of the cavity is provided with an explosive-proof plate and an electric heating coil connected with a temperature control system; the interior of the explosive-proof plate is provided with a micro balance tray and a temperature-sensing probe which is connected with a temperature monitor unit; the upper end of the cavity is provided with a seal cover, a bursting disc and an air outlet; and the temperature control system, the temperature monitor unit and a micro balance are connected with a data collection system. The testing device is applicable to coal oxidation characteristic research under the condition of coal and gas cogeneration, has fireproof and explosive-proof characteristics, and prevents the occurrence of a destroy condition caused by gas explosion in the testing process; the additive amount of a sample is relatively large, and the problem that the additive amount of a coal sample is too small in a traditional research method is overcome.

Description

technical field [0001] The invention relates to the research field of coal mine disaster prevention and control, in particular to a coal oxidation characteristic test device and a test method based on coal and gas symbiosis. Background technique [0002] According to statistics, more than half of coal mines in my country have spontaneous combustion problems, which makes my country one of the countries with frequent coal spontaneous combustion accidents in the world. The research on the oxidation characteristics of coal spontaneous combustion is an important basis for the prevention and control of coal spontaneous combustion. There are many identification methods for coal spontaneous combustion oxidation characteristics, among which thermogravimetric analysis has been recognized by many researchers. The thermogravimetric analysis method can obtain the change law of the quality of the coal oxidation process under a specific atmosphere, and obtain the dynamic oxidation oxygen ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G01N5/04

CPCG01N5/04

Inventor 聂士斌戴广龙张曦周亮周灿

Owner ANHUI UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com