Civil engineering structure reliability evolution and residual life prediction method

A civil engineering structure and life prediction technology, applied in design optimization/simulation, special data processing applications, instruments, etc., can solve problems such as failure to comprehensively consider structural performance degradation reliability, many influencing factors, long time span, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

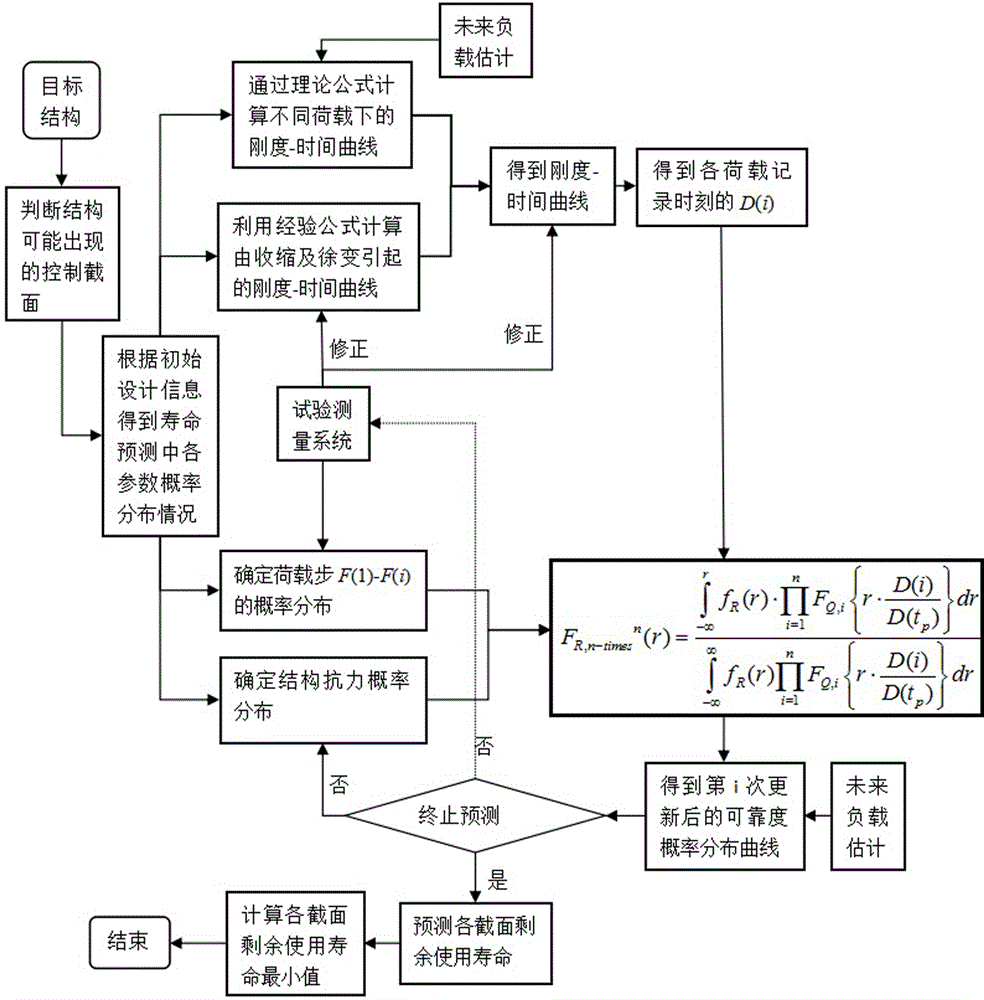

[0053] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

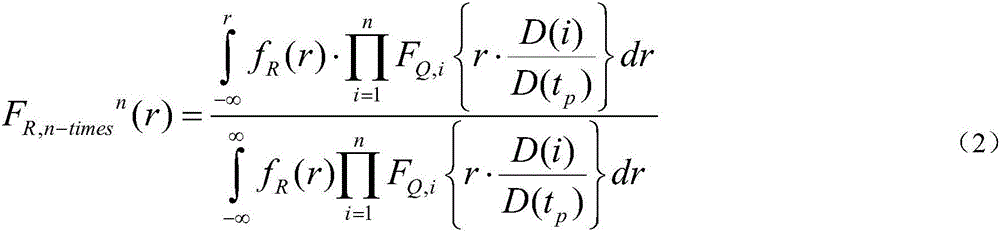

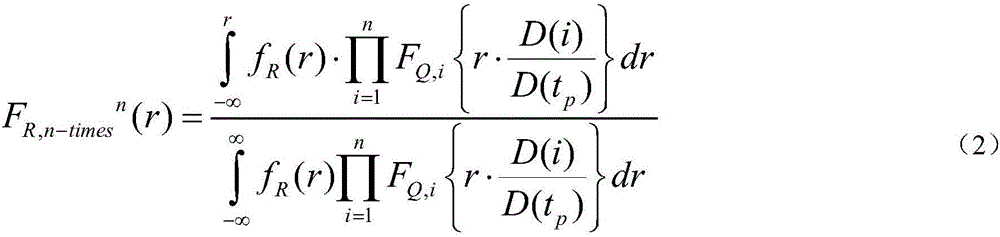

[0054] Such as figure 1 As shown, a method for reliability evolution and remaining life prediction of a civil engineering structure of the present invention, firstly, judge the possible control section of the structure according to numerical analysis or mechanical knowledge; secondly, assume that each parameter obeys the distribution according to the statistical results of the initial design information , and thus calculate the probability distribution of structural resistance and load; thirdly, calculate the stiffness attenuation coefficient D(i) under the influence of load, shrinkage and creep; further, update the structural resistance distribution function, and thus obtain the resistance at this time probability distribution, and obtain the reliability-load curve relationship; then, establish the reliability-time curve to predict the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com