Spring assembly loading and unloading tool

A technology of spring components and loading and unloading workers, which is applied in the field of machinery, can solve the problems of time-consuming, laborious and low efficiency in the process of loading and unloading spring components, and achieve the effect of simple structure, high efficiency and guaranteed controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

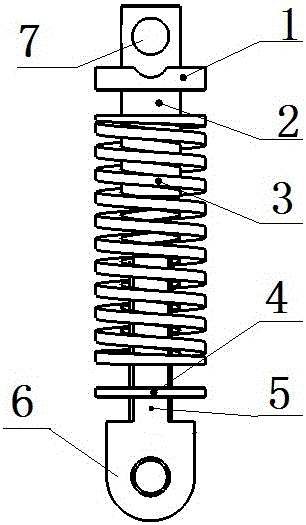

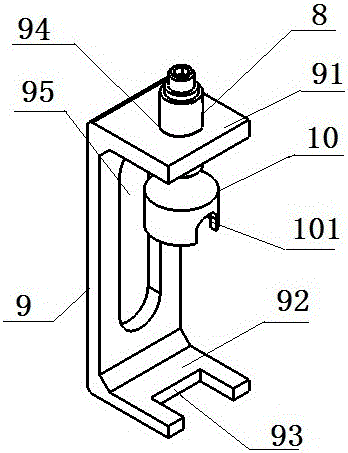

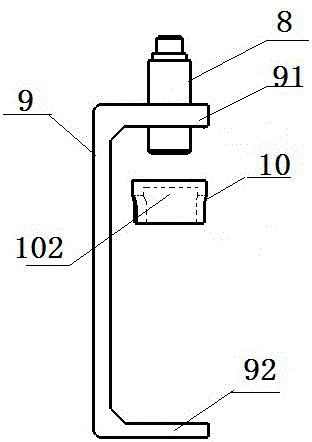

[0024] The specific embodiment of spring assembly loading and unloading frock of the present invention, as Figure 2 to Figure 5 As shown, the frock includes a C-shaped clamping frame 9 with an opening facing the right and a stud screwed on the upper horizontal plate 91 of the clamping frame 9, which is composed of an upper horizontal plate 91, a lower horizontal plate 92, and a connecting plate. 8. The lower horizontal plate 92 constitutes the lower pressing part, and the studs are the actuators. On the lower horizontal plate 92, there is an open slot 93 for the opening of the spring assembly to pass through, which is convenient for loading and unloading. The open slot 93 is U type. The upper horizontal plate 91 is provided with a threaded hole 94 extending along the pressing direction, and the stud 8 is arranged in the threaded hole 94 to cooperate wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com