New energy automobile or charging gun large current connector waterproof structure

A technology for high-current connectors and new energy vehicles. It is applied in the direction of vehicle connectors, connections, and parts of connection devices. It can solve problems such as short-circuit and leakage accidents, short-circuit and leakage, and unreliable sealing of high-current connectors. Achieve the effects of avoiding short circuit and leakage accidents and high sealing reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below according to the accompanying drawings and in conjunction with the embodiments.

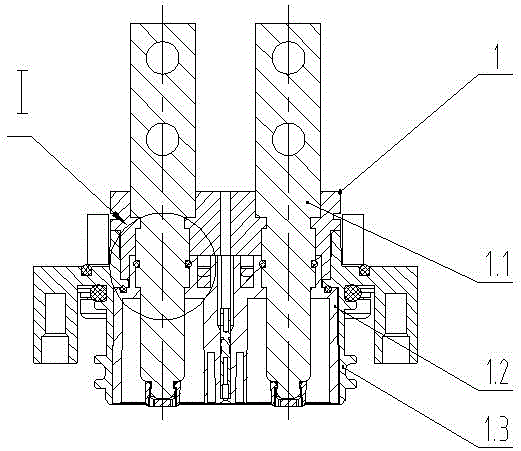

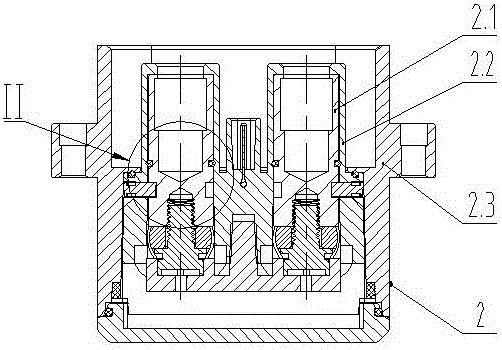

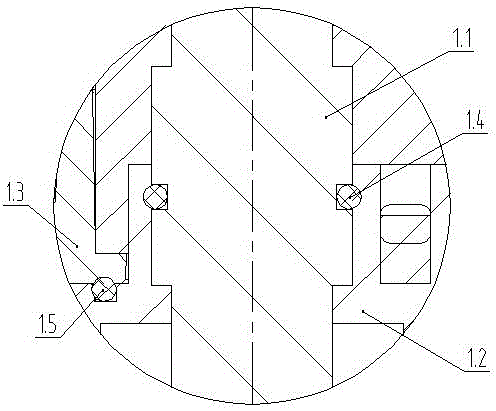

[0020] The waterproof structure of high-current connectors for new energy vehicles or charging guns shown in the attached drawings includes socket 1 and plug 2; socket 1 includes terminal I1.1, socket insulating seat body 1.2, and socket shell 1.3. In this embodiment, terminal I1 .1 is a male terminal (in other embodiments, terminal I1.1 is a female terminal); terminal I1.1 is inserted into the inner hole of the socket insulating seat body 1.2, and the socket insulating seat body 1.2 is inserted into the notch hole of the socket shell 1.3 Middle; the joint of the outer wall of the terminal I1.1 in the socket 1 and the inner hole of the socket insulating seat body 1.2 is provided with a sealing structure I1.4. In this embodiment, the sealing structure I1.4 is a radial sealing structure, and the sealing structure I1.4 Including sealing gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com