Processing method of cooked green scented tea

A processing method and technology for green tea, applied in the direction of tea treatment before extraction, etc., can solve the problems of not lasting fragrance time, affecting the taste of green tea, reducing economic value, etc. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] The processing method of cooked green fragrant tea comprises the following steps: spreading and drying, shaking greens, killing greens, spreading and drying for the second time, kneading, enhancing fragrance, shaping and drying, and further includes the following steps:

[0026] (1) Three times of drying: the tea leaves after the fragrance are spread in a secret room at -3°C for 2.5 minutes, and the thickness of the spread is 5cm;

[0027] (2) Second aroma enhancement: spread the shaped tea leaves on a flat plate, cover the surface of the tea leaves with a film, place the flat plate on the steam inlet pipe, wherein the temperature of the steam is 48°C, and the standing time is 2 hours. The steam is heated up to 105°C, so that the water content of the tea leaves is 30%, and then the tea leaves are put into the aroma enhancing machine, wherein the temperature of the aroma enhancing machine is 65°C, and the aroma enhancing time is 20 minutes;

[0028] (3) Secondary drying:...

Embodiment 2

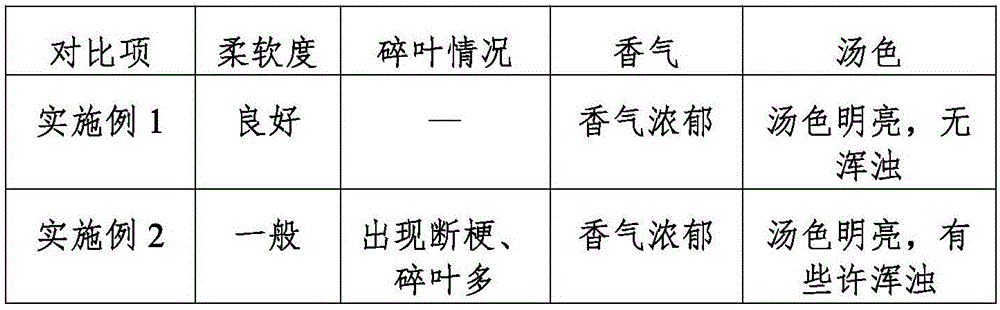

[0037] The main implementation method is as in Example 1, the second airing step is removed to prepare ripe green fragrant tea, and the green tea prepared in Example 1 is compared with the green tea prepared in Example 2, the results are shown in Table 1:

[0038] Table 1

[0039]

Embodiment 3

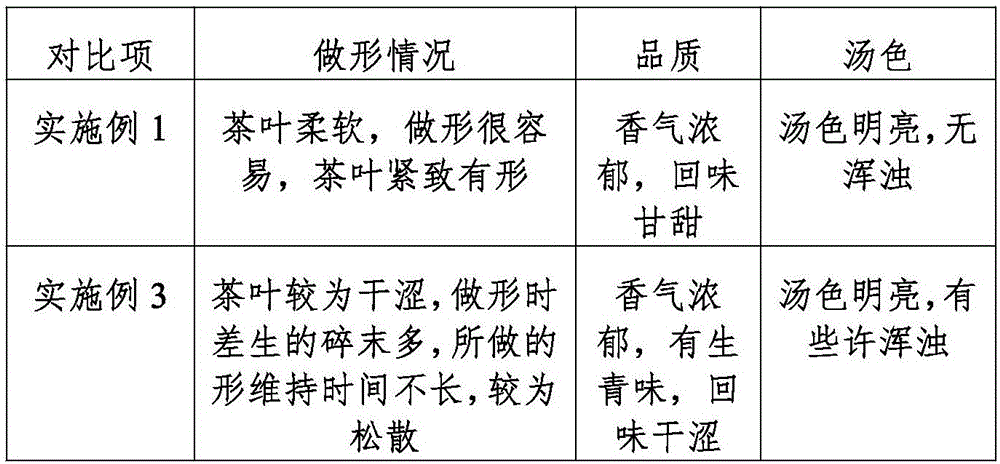

[0041] The main implementation method is as in Example 1, removing the three air-drying steps to prepare ripe green fragrant tea, and comparing the green tea prepared in Example 1 with the green tea prepared in Example 3, the results are shown in Table 2:

[0042] Table 2

[0043]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com