A kind of white jade snail tea processing method

A processing method and technology of snail tea, applied in the fields of white jade snail tea processing and tea processing, can solve the problems of different rolling weight, difficulty in controlling the curled shape of jade snail tea, and inability to mass-produce it.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

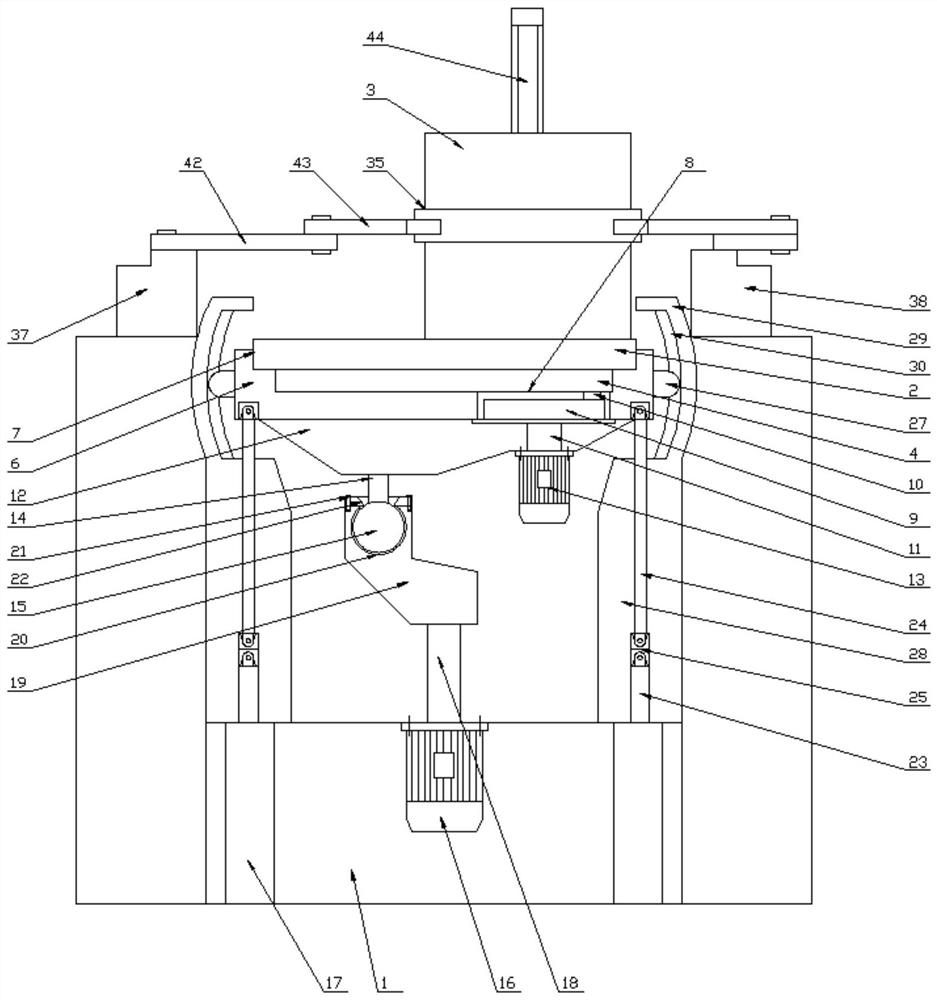

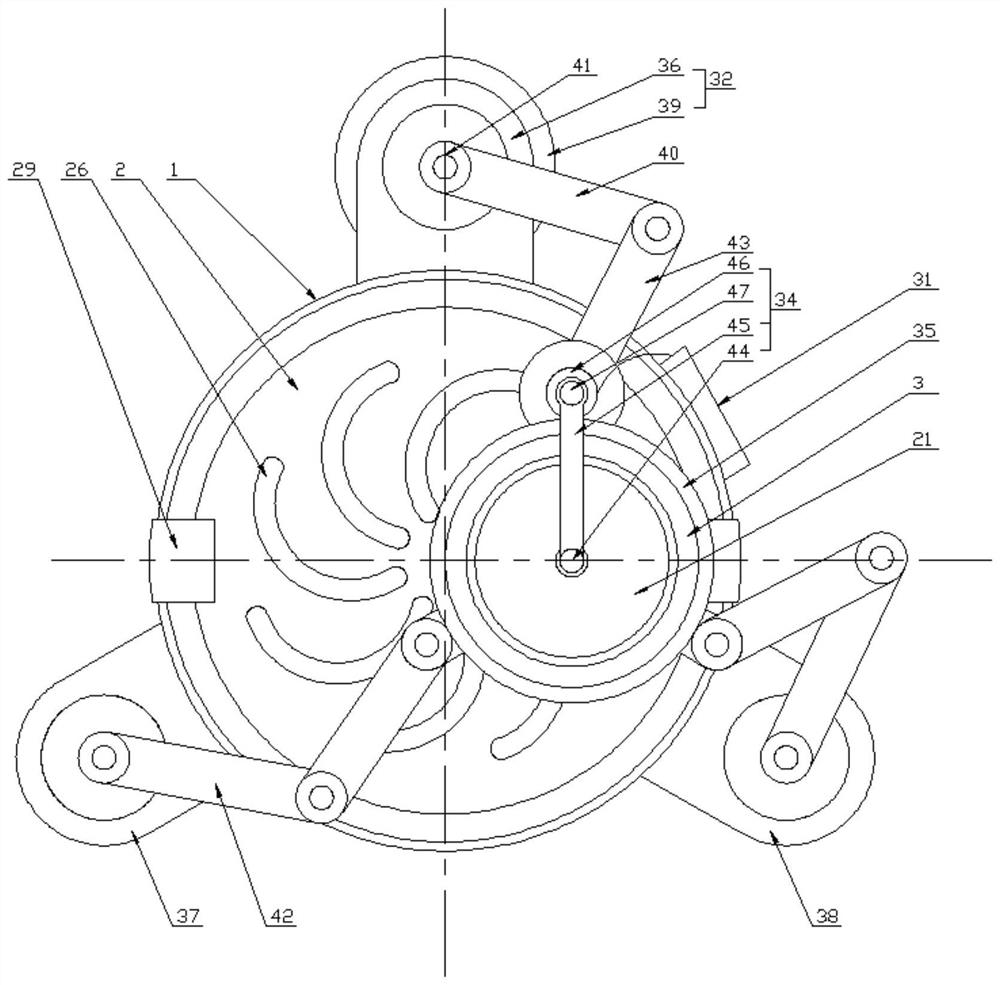

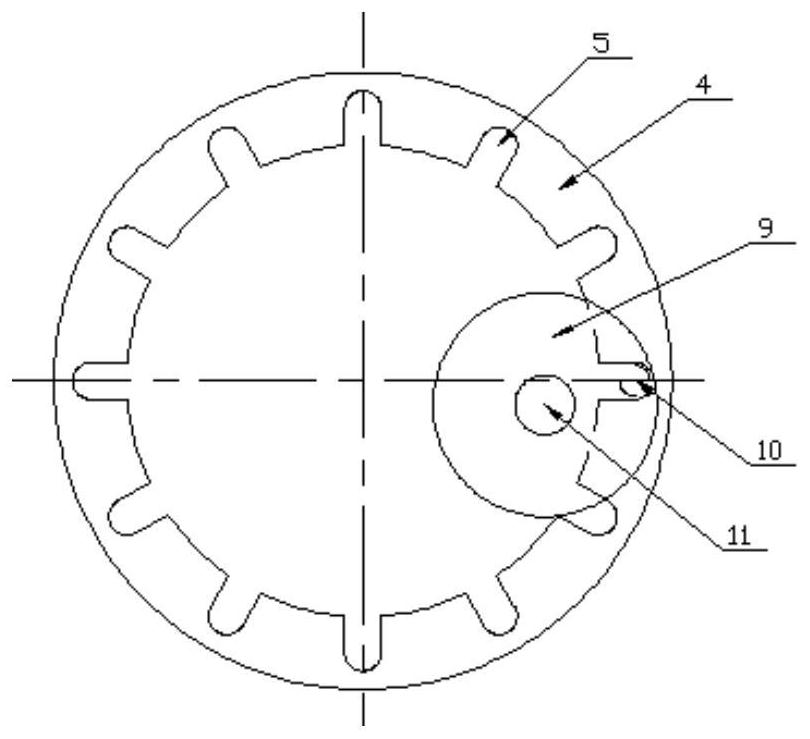

Method used

Image

Examples

Embodiment 1

[0034] A processing method of white jade snail tea, the processing method is as follows:

[0035](1) Grading of raw materials: 5 kg of albino buds and leaves of Anji Baiyecha No. 1 produced in accordance with NY / T5018 with the same tenderness, uniformity, clarity and freshness are collected in batches, and the pair of clipped leaves and single leaves are removed Leaves, fish leaves and non-tea sundries are classified according to special grade, first grade and second grade. The number of buds, leaves and buds in the special grades accounts for 96%, and the number of buds and leaves in the first grades The quantity of leaf one bud and one leaf accounts for 85%, and the quantity of bud leaf one bud two leaves accounts for 70% in the described secondary product, gets fresh leaf raw material;

[0036] (2) Treatment of fresh leaves: spread the raw materials of fresh leaves in a spreading room with room temperature less than 25°C with a thickness of 4cm. The raw materials of fresh l...

Embodiment 2

[0044] A processing method of white jade snail tea, the processing method is as follows:

[0045] (1) Grading of raw materials: 6 kg of albino buds and leaves of Anji Baiyecha No. 1 produced in accordance with NY / T5018 with the same tenderness, uniformity, clarity and freshness of fresh leaves are collected in batches, and the pair of clipped leaves and single leaves are removed Leaves, fish leaves and non-tea sundries are classified according to special grade, first grade and second grade. The number of buds, leaves and buds in the special grades accounts for 96%, and the number of buds and leaves in the first grades The quantity of leaf-bud-one leaf accounts for 84%, and the quantity of bud-leaf-bud-two-leaf accounts for 63% in the described secondary product, gets fresh leaf raw material;

[0046] (2) Treatment of fresh leaves: spread the raw materials of fresh leaves in a spreading room with a room temperature lower than 25°C, with a thickness of 3 cm. The time is 4.5h, t...

Embodiment 3

[0054] A processing method of white jade snail tea, the processing method is as follows:

[0055] (1) Grading of raw materials: First, 7kg of albino buds and leaves of Anji Baiyecha No. 1 produced in accordance with NY / T5018 with the same tenderness, uniformity, clarity and freshness are collected in batches, and the pair of clipped leaves and single leaves are removed. Leaves, fish leaves and non-tea sundries are classified according to special grade, first grade and second grade. The number of buds, buds and leaves in the special grades accounts for 98%, and the number of buds and leaves in the first grades The quantity of leaf one bud and one leaf accounts for 88%, and the quantity of bud leaf one bud two leaves accounts for 67% in the described secondary product, obtains fresh leaf raw material;

[0056] (2) Fresh leaf treatment: spread fresh leaf raw materials in a spreading room with room temperature less than 25°C, with a thickness of 3.5cm. When the fresh leaf raw mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com