Method for regulating sugar, nitrogen and nicotine of extract of papermaking-method reconstituted tobacco

A technology for reconstituting tobacco leaves and extracting liquid, which is applied in the directions of tobacco, tobacco preparation, application, etc., can solve the problems such as the difficulty of stabilizing the chemical composition of tobacco sheets and the effective control of the chemical composition of the extracting liquid.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

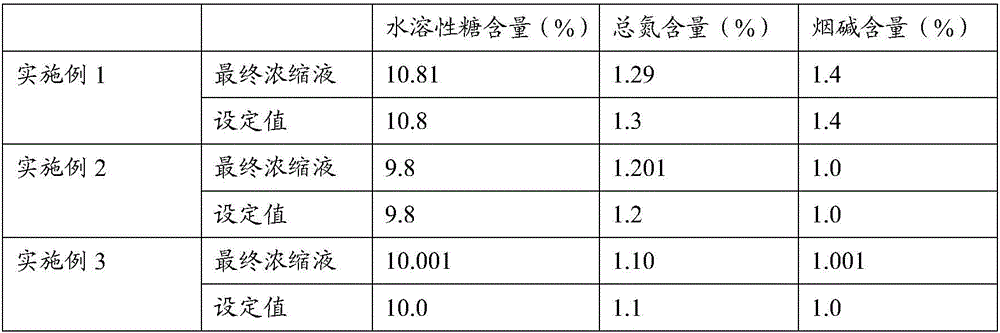

Embodiment 1

[0026] (1) Carry out impurity removal to tobacco waste material, wash stem pretreatment;

[0027] (2) extracting the raw material after impurity removal;

[0028] (3) Carry out solid-liquid separation after extraction is completed, obtain extract;

[0029] (4) After purifying and removing the slag from the extract obtained in step (3), measure the total water-soluble sugar content of 2.83%, the content of total nitrogen of 0.34%, and the content of nicotine of 0.37% in the extract;

[0030] (5) Determine that the required water-soluble total sugar content set value in the concentrated solution is 10.80%, the total nitrogen content set value is 1.30%, and the nicotine content set value is 1.40%, calculate the water-soluble total sugar, total nitrogen and The concentration of nicotine that can reach or slightly exceed the set value is 38.24%;

[0031] (6) Concentrate the measured extract according to the set value and concentration determined in step (5), the concentration tem...

Embodiment 2

[0040] (1) Carry out impurity removal to tobacco waste material, wash stem pretreatment;

[0041] (2) extracting the raw material after impurity removal;

[0042] (3) Carry out solid-liquid separation after extraction is completed, obtain extract;

[0043] (4) After purifying and removing the slag from the extract obtained in step (3), it is measured that the water-soluble total sugar content in the extract is 2.75%, the total nitrogen content is 0.37%, and the nicotine content is 0.29%;

[0044] (5) Determine that the required water-soluble total sugar content set value in the concentrated solution is 9.80%, the total nitrogen content set value is 1.20%, and the nicotine content set value is 1.00%, and calculate the water-soluble total sugar, total nitrogen content Both nicotine and nicotine can reach or slightly exceed the set value of 35.64%;

[0045] (6) Concentrate the measured extract according to the set value and concentration determined in step (5), the concentratio...

Embodiment 3

[0056] (1) Carry out impurity removal to tobacco waste material, wash stem pretreatment;

[0057] (2) extracting the raw material after impurity removal;

[0058] (3) Carry out solid-liquid separation after extraction is completed, obtain extract;

[0059] (4) After purifying and removing the slag from the extract obtained in step (3), it is measured that the water-soluble total sugar content in the extract is 2.45%, the total nitrogen content is 0.27%, and the nicotine content is 0.23%;

[0060] (5) Determine the set value of the water-soluble total sugar nicotine content required in the concentrated solution to be 10.00%, the set value of the total nitrogen nicotine content to be 1.10% and the set value of the nicotine content to be 1.00%, and calculate the water-soluble total The concentration of sugar, total nitrogen and nicotine can reach or slightly exceed the set value is 43.48%;

[0061] (6) Concentrate the measured extract according to the set value and concentratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com