Full-automatic cooking robot

A robotic and fully automatic technology, applied in cooking utensils, household utensils, applications, etc., can solve problems such as fuzzy detection and control methods of rice cookers, and achieve the effect of simple and ingenious structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

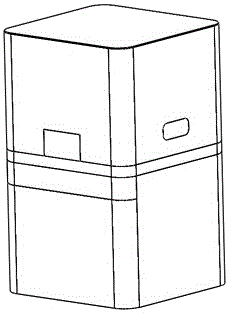

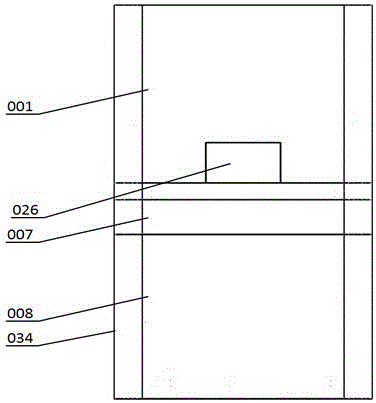

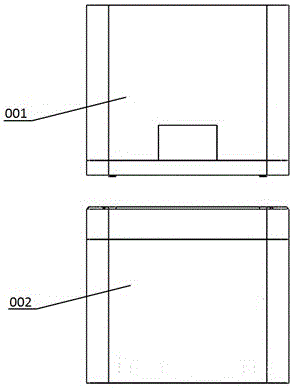

[0031] Such as Figure 1 to Figure 13 As shown, this embodiment discloses a fully automatic rice cooking robot, which is composed of an upper machine position 001 and a lower machine position 002 to form a fully automatic rice cooking robot, which includes a frame 034, a rice storage bin 003, a rice fetching system 004, a cleaning Stirring system 006, water adding and draining system 005, heating and cooking system 008, pressure sensing (weighing) system 010, liner pot lifting system 009, liner cover device 007 and controller 026, rack 034 in order from top to bottom Set as the upper machine position 001 and the lower machine position 002, the rice storage bin 003 is installed on the upper machine position 001, the rice fetching system 004 is installed on the bottom plate 020 of the upper machine position and connected with the discharge port 035 of the rice storage bin, and the rice measuring motor 018 drives the rotation movement, the cleaning and mixing system 006 is instal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com