Multifunctional vertical grilling machine

A multi-functional, frying and grilling technology, which is applied in the directions of grills/barbecue grids, frying pans, toasting devices, etc., can solve the problems of uneven frying and scorching of food, single function, and unsatisfactory food drainage. To achieve the effect of shortening the frying time and uniform surface burnt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings of the description.

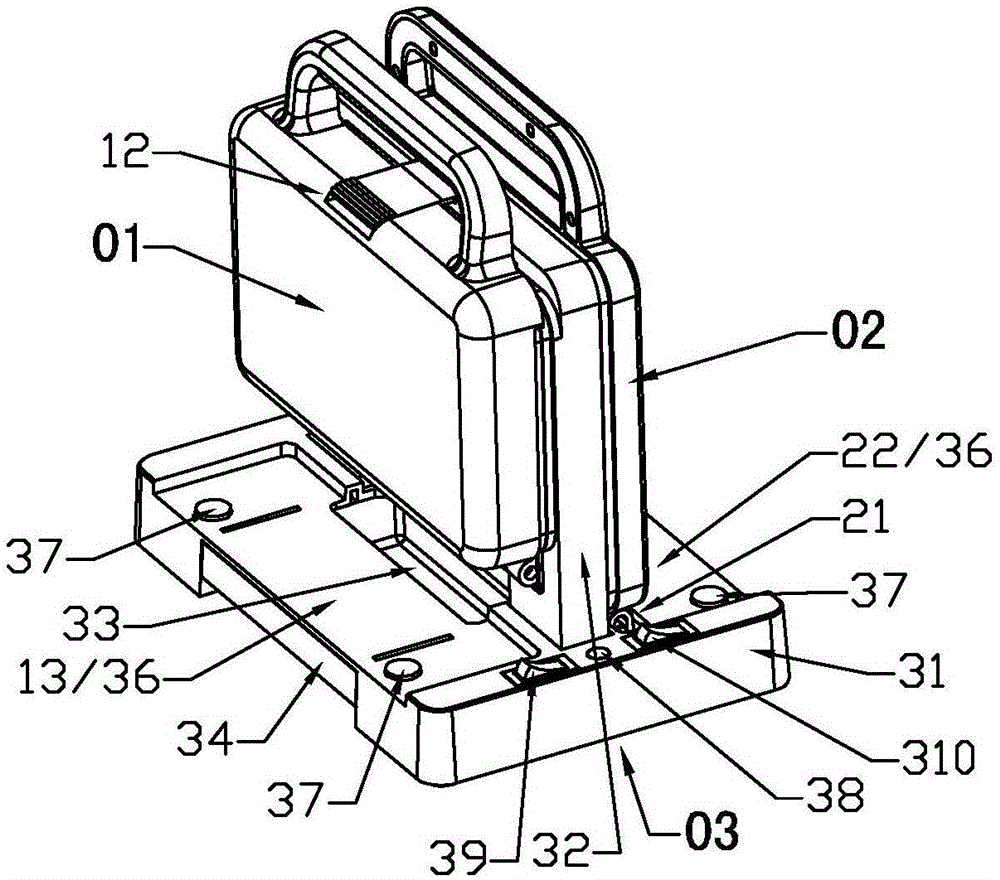

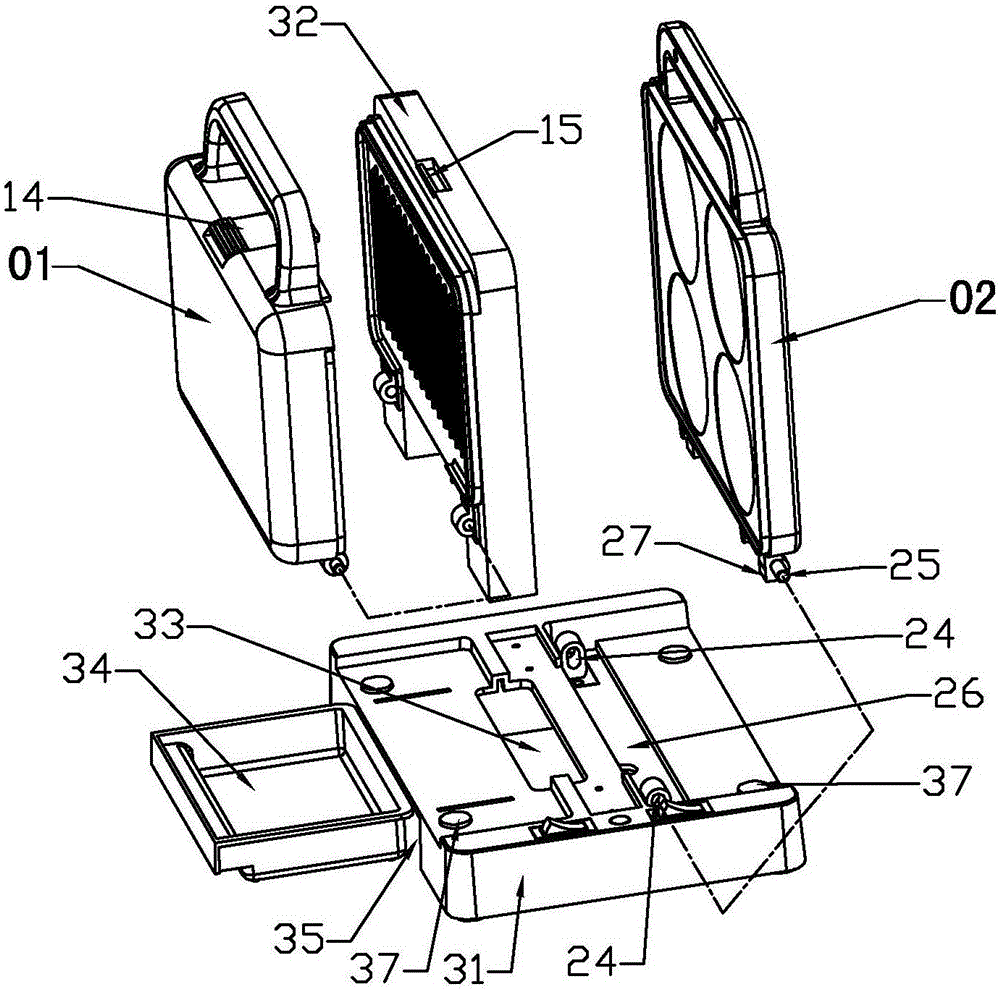

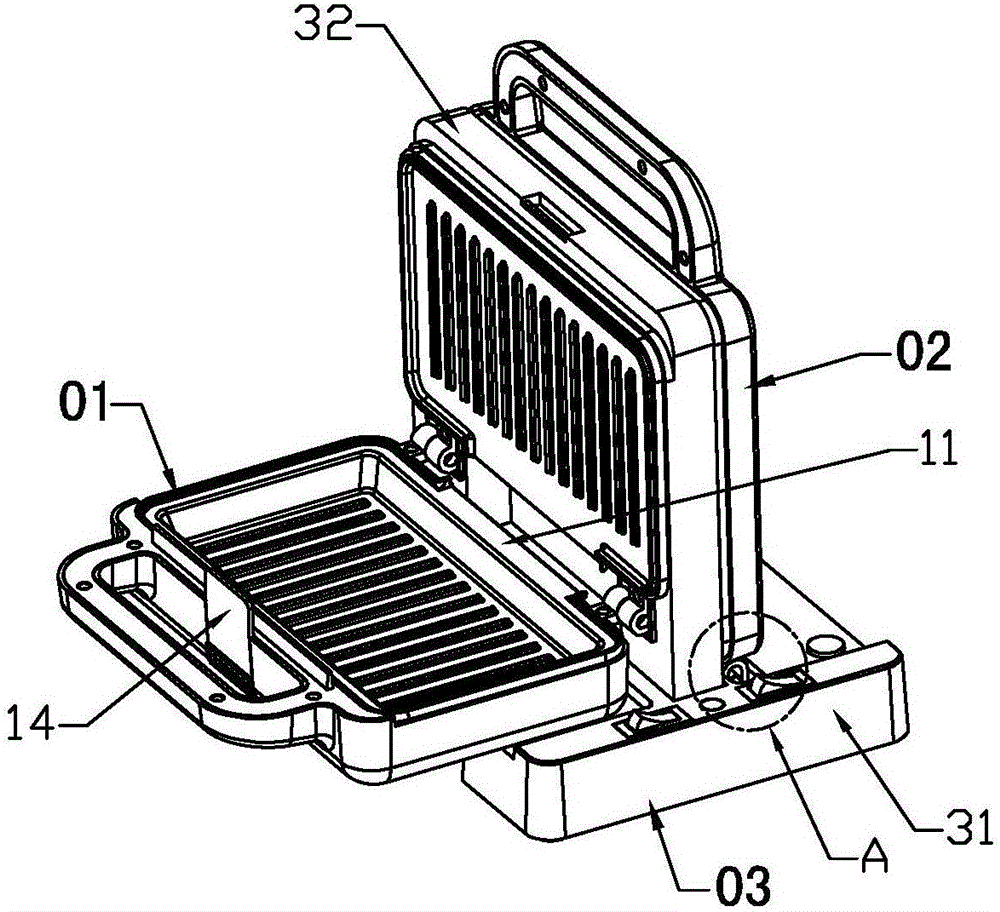

[0035] Such as Figure 1-7 Shown, the multifunctional vertical grill of the present invention comprises:

[0036] The seat body 03 has a base 31 and an upright portion 32 extending upward from the middle of the base, an oil drain hole 33 is opened on the base 31, and an oil collection box 34 corresponding to the oil drain hole 33 is arranged on the lower side of the base 31;

[0037] The first grilling body 01 is mounted on the side of the upright portion 32 on the seat body 03 through the cooperation of the shaft and the hole so that it can be in a vertical state (see figure 1 , 2 , 4) and flat state (see image 3 , 5 ) to switch positions, on which there is a drain nozzle 11 corresponding to the drain hole 33, which is locked in a vertical state by the first locking structure 12 and is closed with the vertical part 32 when it is in the vertical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com