A granular bed filter dust removal device

A particle bed filtration and particle bed filter technology, which is applied in the direction of dispersed particle filtration, combined device, transportation and packaging, etc., can solve the problems of increased filtration load, more serious blade wear, and blade wear, so as to improve filtration efficiency, The effect of continuous high-efficiency filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

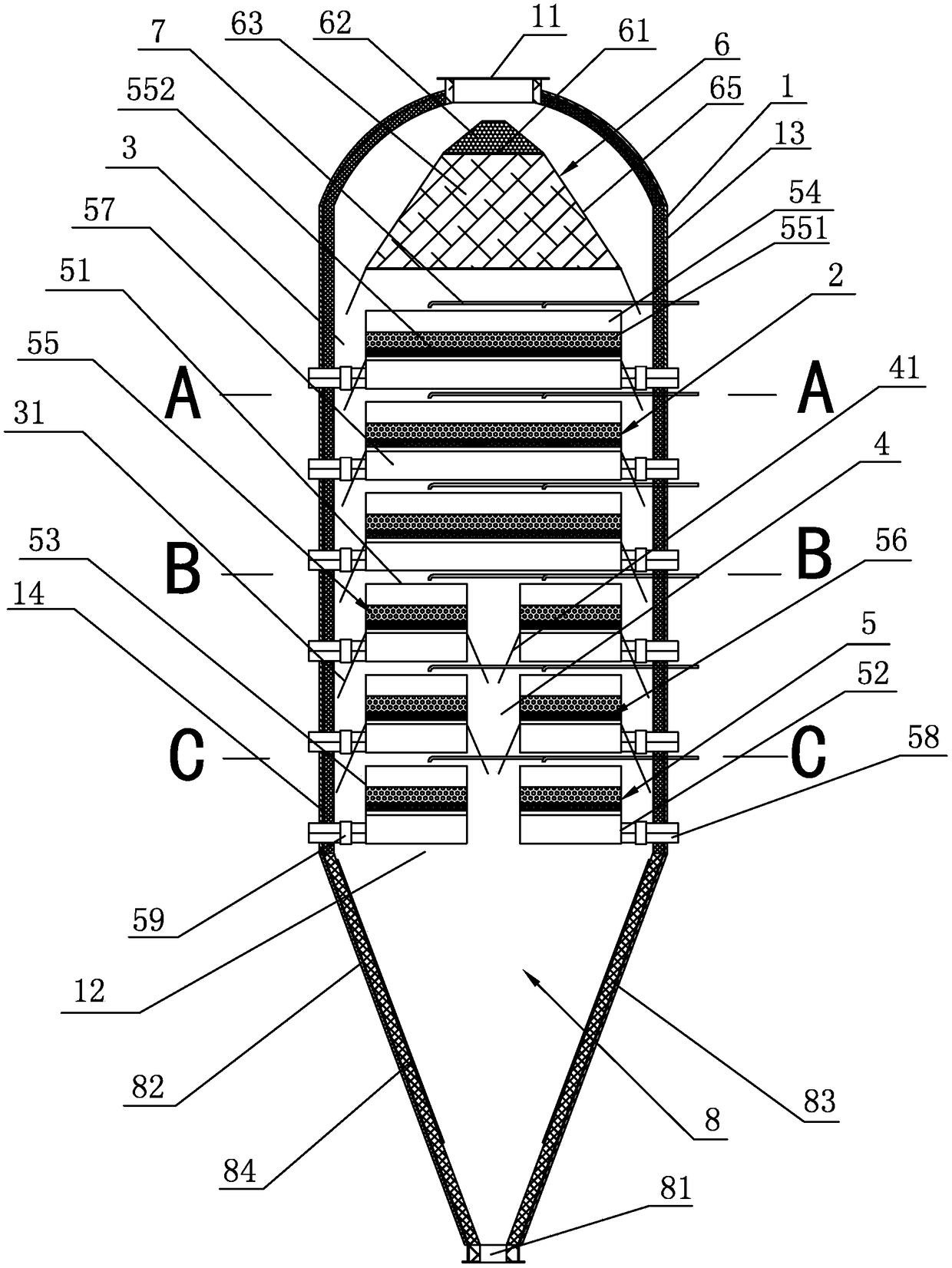

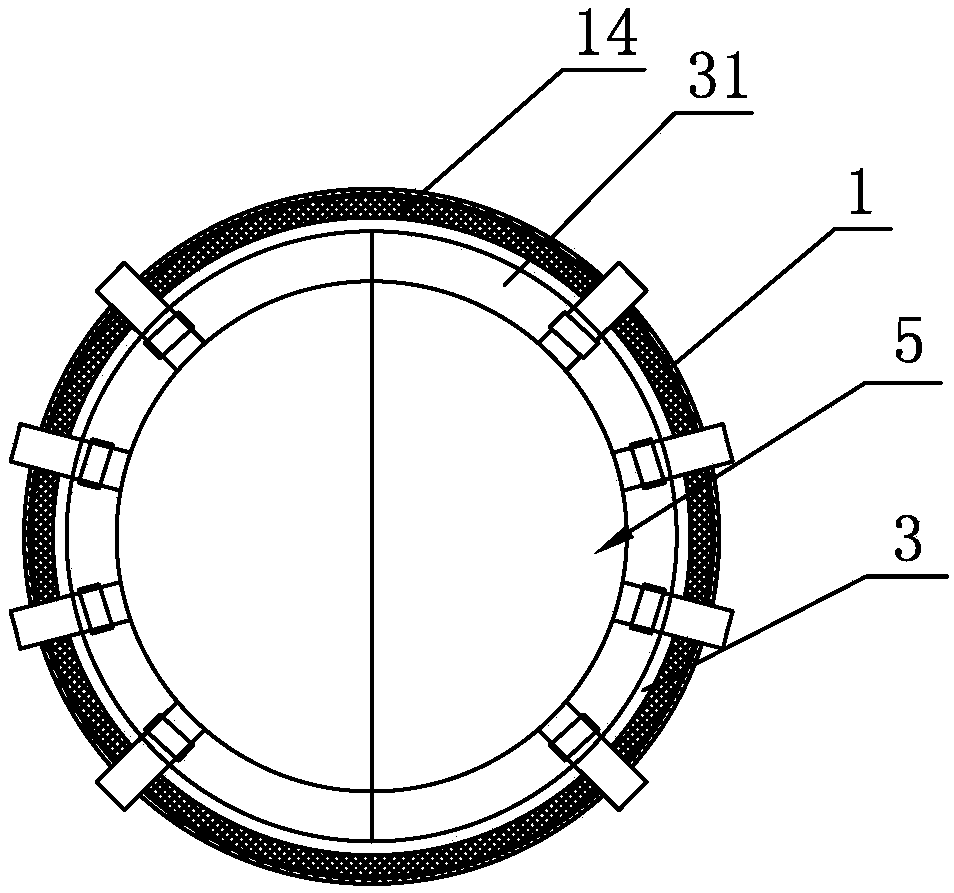

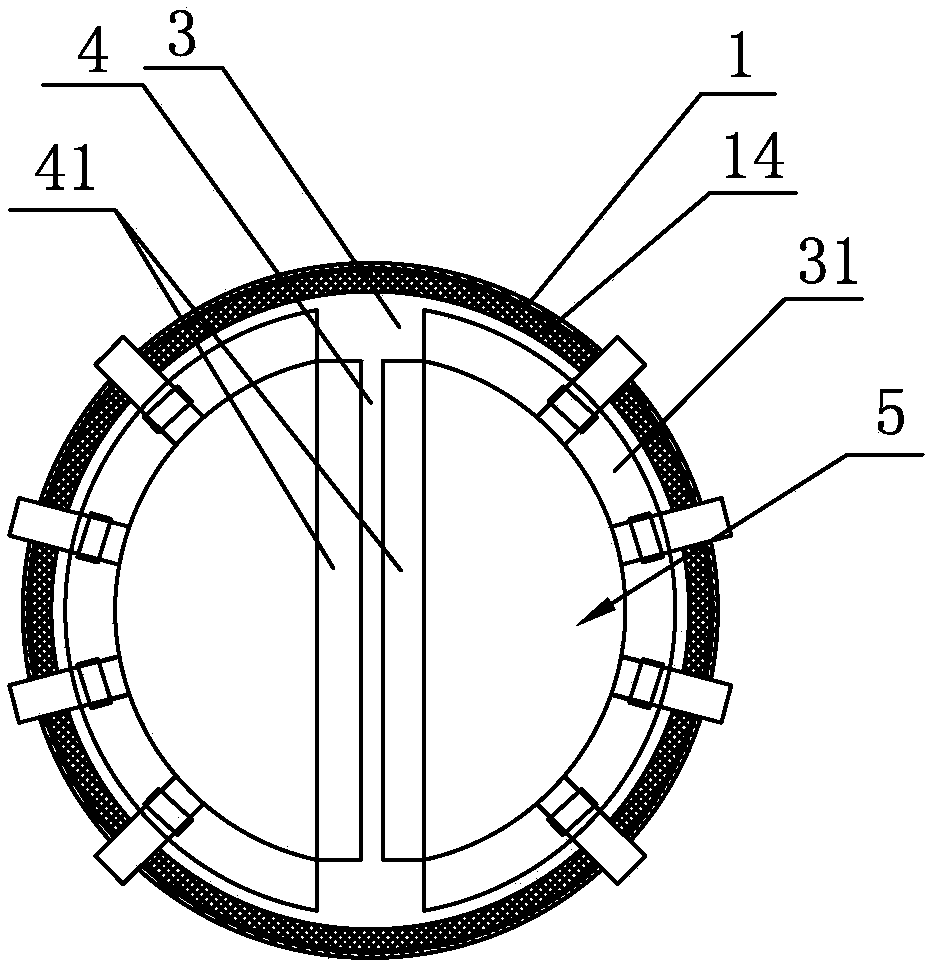

[0026] A kind of particle bed filter dust removal device that present embodiment proposes, such as Figure 1a to Figure 1d As shown, it includes an outer casing 1 with a circular cross-section. The top of the outer casing 1 is provided with a dusty gas inlet 11 communicating with the upstream air intake pipe (not shown in the figure), and the bottom of the outer casing 1 is provided with a dust exhaust. Outlet 12, the interior of the outer shell 1 is centered in the vertical direction with six layers of granular bed filters 2 that have gaps with the inner wall of the outer shell 1, and the gaps between the inner wall of the outer shell 1 and the outer peripheries of all granular bed filters 2 As the airflow chamber 3, so that the airflow chamber 3 is located at the periphery of the particle bed filter 2, such an arrangement makes there be a large enough space between the periphery of the particle bed filter 2 and the inner wall of the outer shell 1, which is convenient for pers...

Embodiment 2

[0035] A kind of particle bed filter dust removal device that present embodiment proposes, such as figure 2 As shown, its structure is not much different from that of the particle bed filter and dust removal device of Embodiment 1, the difference is only that: the back blowing gas settling chamber 4 in the particle bed filter and dust removal device of the present embodiment only runs through two layers of particle beds The filter 2 is only the particle bed filter 2 of the lowest layer and the particle bed filter 2 of the second lowest layer. That is, the particle bed filter and dust removal device of this embodiment includes an outer casing 1 with a circular cross section, the top of the outer casing 1 is provided with a dust-containing gas inlet 11 communicating with the upstream air intake pipe, and the bottom of the outer casing 1 is provided with a dust outlet. 12. The interior of the outer shell 1 is vertically centered with six layers of granular bed filters 2 that hav...

Embodiment 3

[0038] A kind of particle bed filter dust removal device that present embodiment proposes, such as Figure 3a and Figure 3b As shown, its structure is not much different from the structure of the particle bed filter and dust removal device of Embodiment 1, the difference is only that: the back blowing gas settling chamber 4 in the particle bed filter and dust removal device of the present embodiment runs through all the particle bed filters 2. That is, the particle bed filter and dust removal device of this embodiment includes an outer casing 1 with a circular cross section, the top of the outer casing 1 is provided with a dust-containing gas inlet 11 communicating with the upstream air intake pipe, and the bottom of the outer casing 1 is provided with a dust outlet. 12. The interior of the outer shell 1 is vertically centered with six layers of granular bed filters 2 that have gaps with the inner wall of the outer shell 1, and the gaps between the inner wall of the outer sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com