Intelligent control straw treatment dust fall auxiliary system

An auxiliary system and intelligent control technology, applied to the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve the problems of feed secondary pollution, environmental pollution, low degree of automation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

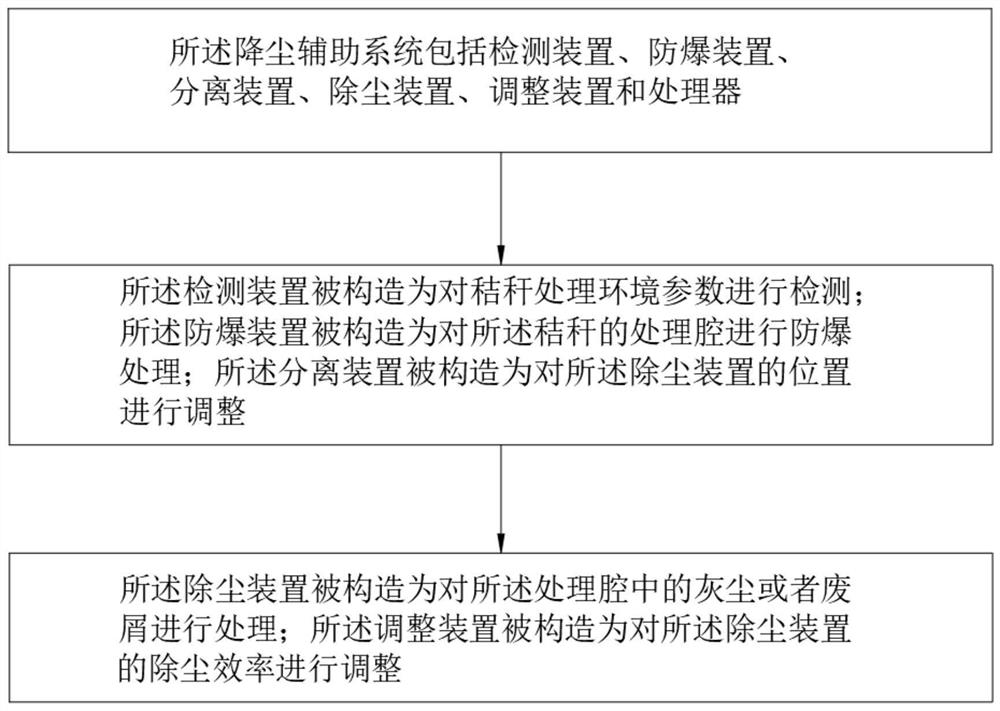

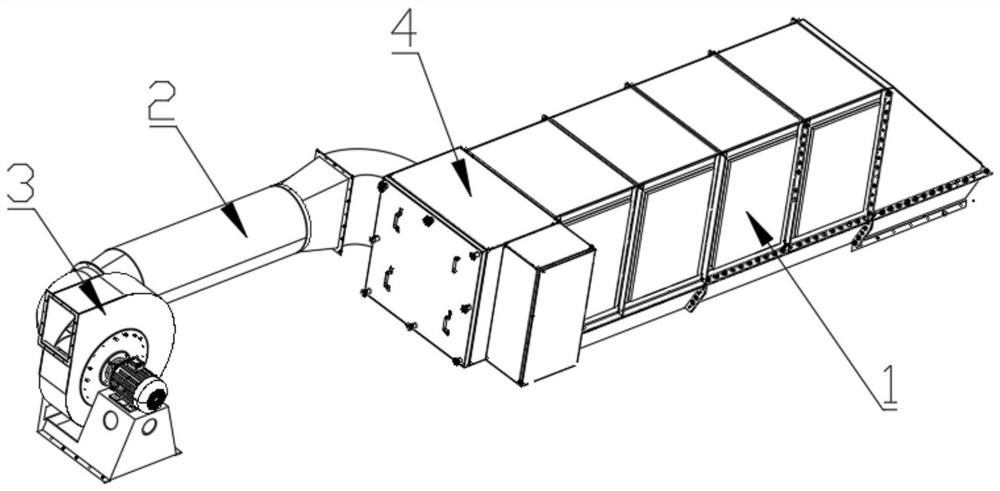

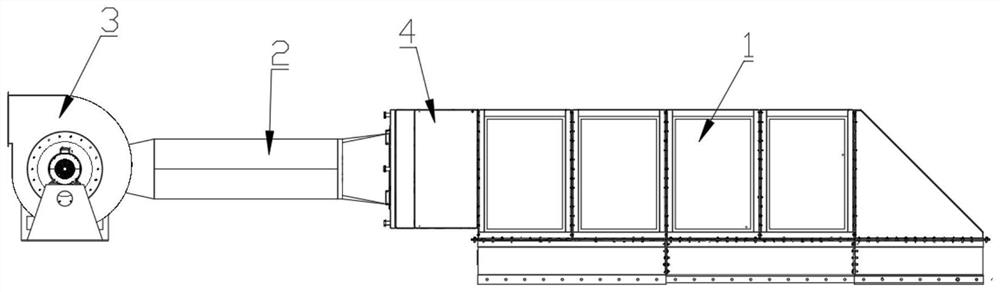

[0032] Embodiment 1: An intelligently controlled dust reduction auxiliary system for straw processing, the dust reduction auxiliary system includes a detection device, an explosion-proof device, a separation device, a dust removal device, an adjustment device and a processor, and the detection device is configured to monitor the straw processing environment parameter detection; the explosion-proof device is configured to perform explosion-proof treatment on the straw processing chamber; the separation device is configured to adjust the position of the dust removal device; the dust removal device is configured to The dust or waste in the chamber is processed; the adjustment device is configured to adjust the dust removal efficiency of the dust removal device;

[0033] Optionally, the detection device includes a set of detection probes, an offset mechanism and a data collector, and the data collector is configured to collect data on a set of the detection probes; the offset mecha...

Embodiment 2

[0038] Embodiment 2: The existing straw is being recycled, or it is not cut directly, or it is traditionally cut manually, and a small part is cut by machinery. Whether it is manual cutting or existing mechanical cutting, the cutting efficiency is low. It is difficult to form industrialization and scale, and it will produce secondary pollution during the cutting process, and the safety cannot be well guaranteed. To provide a flexible multi-functional roller-pressed straw cutting machine, at the same time, It is very easy to produce debris or dust, which will cause a certain degree of pollution to the environment; in addition, there are also common problems such as secondary pollution in feed production, poor dust suppression effect, and low degree of automation;

[0039] An intelligently controlled dust reduction auxiliary system for straw processing is provided, the dust reduction auxiliary system includes a detection device, an explosion-proof device, a separation device, a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com