A kind of preparation method of iron-molybdenum composite doped oxide

A compound doping and oxide technology, which is applied in the preparation of organic compounds, carbon-based compounds, chemical instruments and methods, etc., to achieve the effect of uniform doping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

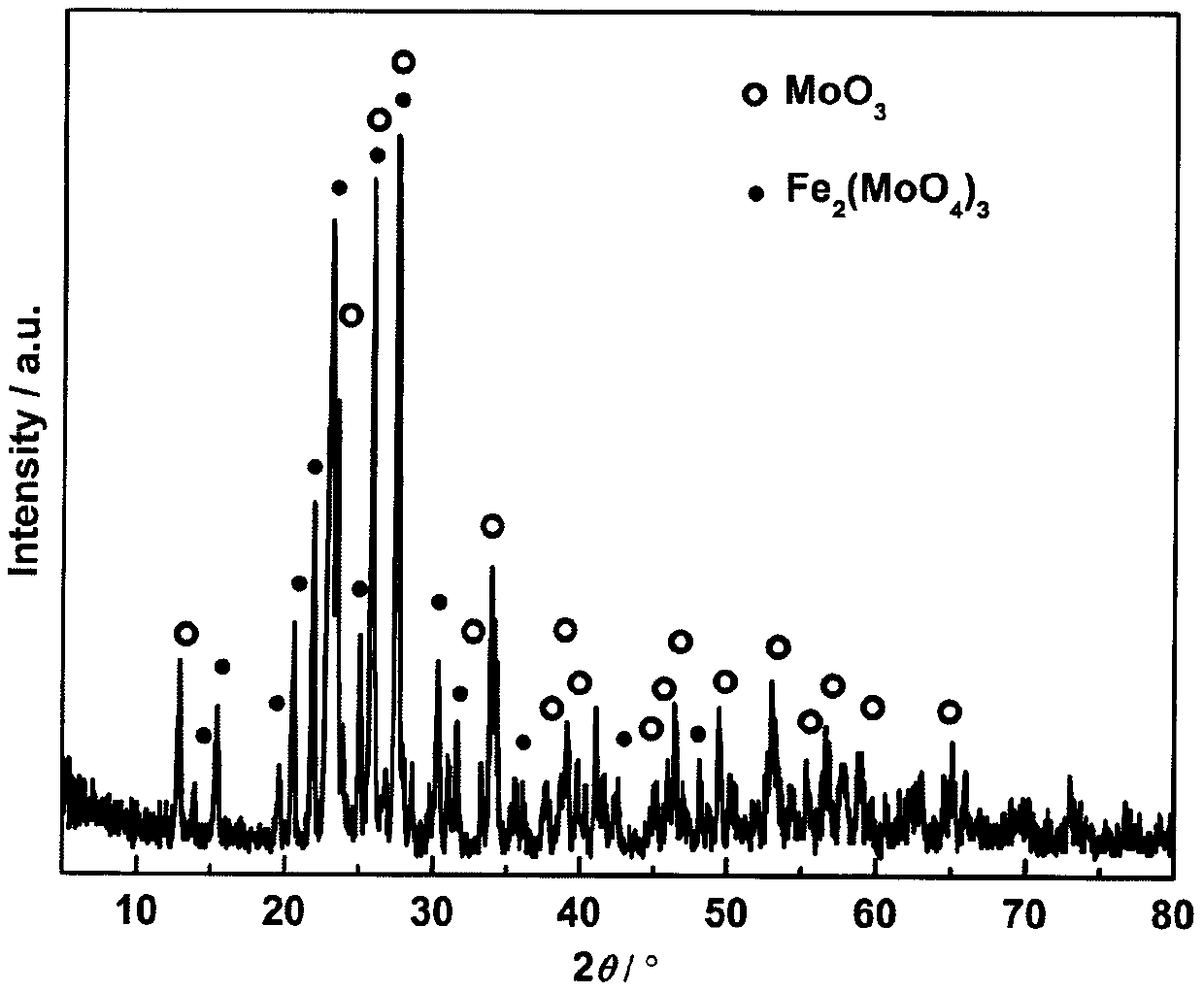

[0018] Weigh 0.02mol of ferric sulfate and 0.05mol of ammonium paramolybdate, dissolve them in 50mL of water respectively, add 0.03mol of citric acid into the ferric sulfate solution, pour the ammonium paramolybdate solution into the iron solution while stirring, and then add 0.02 mol of acrylamide, 0.004mol of N,N'-methyleneacrylamide, and 0.0012mol of azobisisobutyronitrile were added under the condition of stirring. The mixed solution will solidify quickly to form a precursor, take out the precursor, divide it into pieces, and roast it at 450°C for 1 hour to obtain the iron-molybdenum composite oxide catalytic material. observed by Fe 2 (MoO 4 ) 3 and MoO 3 Coexisting complex phases.

Embodiment 2

[0020] Weigh 0.015mol of ferric sulfate, 0.04mol of ammonium paramolybdate, and 0.005mol of ammonium metavanadate, mix the molybdenum and vanadium salts directly, dissolve the raw materials in 50mL of water, and add 0.03mol of ethylenediaminetetraacetic acid into the ferric sulfate solution , Pour the molybdenum and vanadium solutions into the iron solution while stirring, then add 0.03mol acrylamide, 0.005mol N, N'-methyleneacrylamide, and add 0.0015mol azobisisobutyronitrile under stirring conditions. The mixed solution will solidify rapidly to form a precursor, which is taken out, divided into pieces, and calcined at 600°C for 1 hour to obtain the iron-molybdenum-vanadium composite doped oxide catalytic material.

Embodiment 3

[0022] Weigh 0.02 mol of iron sulfate, 0.05 mol of ammonium paramolybdate, and 0.005 mol of cobalt acetate, mix the iron and cobalt salts directly, dissolve the raw materials in 50 mL of water, and add 0.03 mol of ethylenediaminetetraacetic acid into the solution of iron sulfate and cobalt , Pour the molybdenum solution into the iron solution while stirring, then add 0.025mol acrylamide, 0.004mol N, N'-methyleneacrylamide, and add 0.0013mol azobisisobutyronitrile under stirring conditions. The mixed solution will solidify quickly to form a precursor, which is taken out, divided into pieces, and calcined at 500°C for 1 hour to obtain the iron-molybdenum-cobalt composite doped oxide catalytic material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com