Caking agent

A technology of binder and surfactant, which is applied in the field of molding sand binder and molding materials in the field of foundry, and can solve the problems of poor sand mold collapse and difficult recycling of old sand.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

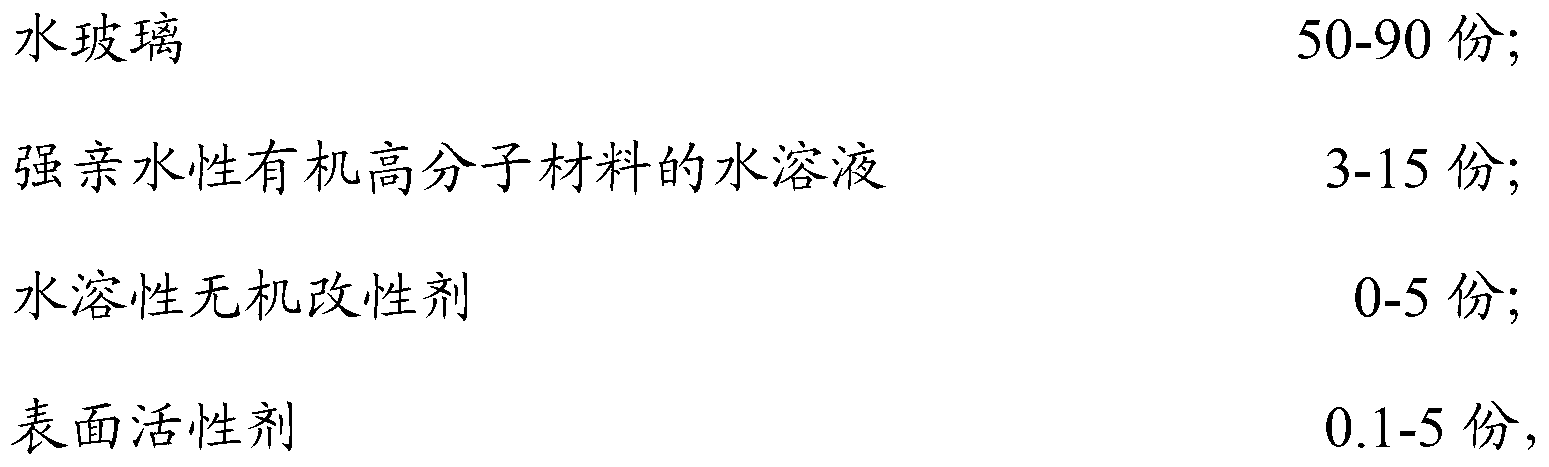

Method used

Image

Examples

Embodiment 1

[0028] Add 80 kg of water glass into the YT22 high-speed disperser (manufactured by Sichuan Yongtong Machinery Equipment Co., Ltd.), start stirring, slowly add 10 kg of polyacrylamide solution, 4 kg of sodium tetraborate, and 3 kg of sodium stearate, and mix for two hours Finally, the binder S1 is obtained.

[0029] Among them, the modulus M of water glass is 2.6, and the density is 1.35g / cm 3 ; The number average molecular weight of polyacrylamide is 3 million, and the weight percentage of polyacrylamide in its aqueous solution is 35wt%.

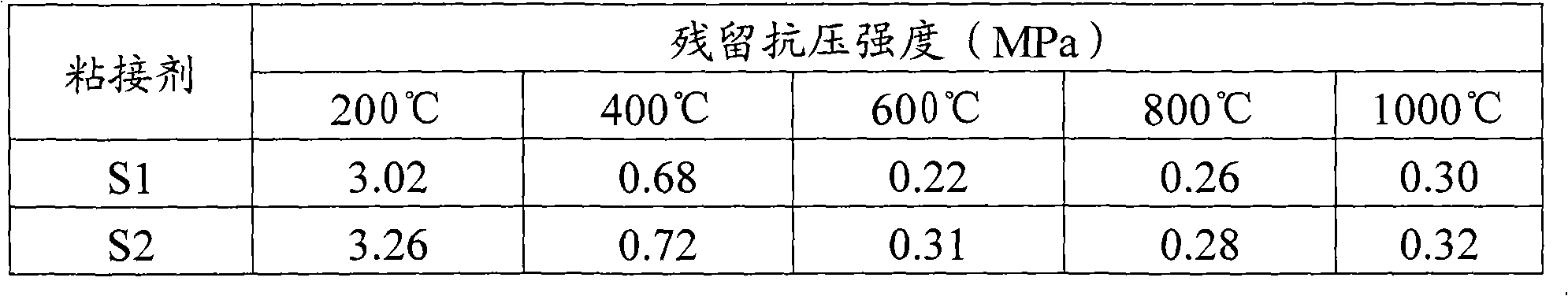

[0030] In this example, by controlling the number-average molecular weight of polyacrylamide to 3 million and making it into an aqueous solution with a concentration of 35 wt%, the temperature at high temperature (referring to the temperature during casting, such as the temperature during casting aluminum alloy is 500-700°C) is greatly improved. The decomposable high molecular content makes the sand mold prepared with this binder have exce...

Embodiment 2

[0033] Add 88 kg of water glass into the YT22 high-speed disperser (manufactured by Sichuan Yongtong Machinery Equipment Co., Ltd.), start stirring, slowly add 5 kg of polyacrylamide solution, 3 kg of sodium tripolyphosphate, 4 kg of potassium stearate, mix two Binder S2 was obtained after 1 hour.

[0034] Among them, the modulus M of water glass is 1.9, and the density is 1.6g / cm 3 ; The number average molecular weight of polyacrylamide is 1 million, and the weight percentage of polyacrylamide in its aqueous solution is 45wt%.

Embodiment 3

[0036] Add 50 kilograms of water glass into the YT22 high-speed disperser (manufactured by Sichuan Yongtong Machinery Co., Ltd.), start stirring, and slowly add 15 kilograms of polymethacrylamide solution, 5 kilograms of sodium hexametachlorate, and 5 kilograms of potassium stearate , to obtain binder S3 after mixing for two hours.

[0037] Among them, the modulus M of water glass is 3.5, and the density is 1.5g / cm 3 ; The number average molecular weight of polyacrylamide is 5 million, and the weight percentage of polyacrylamide in its aqueous solution is 20wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com