Apricot liquid essence for cigarettes and production process thereof

A production process and liquid technology, applied in essential oils/spices, tobacco, applications, etc., can solve the problems of uneven aroma of tobacco leaves, poor aroma durability, etc., to increase the sweetness of the mouth, promote the harmonization effect, and improve the aroma. degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

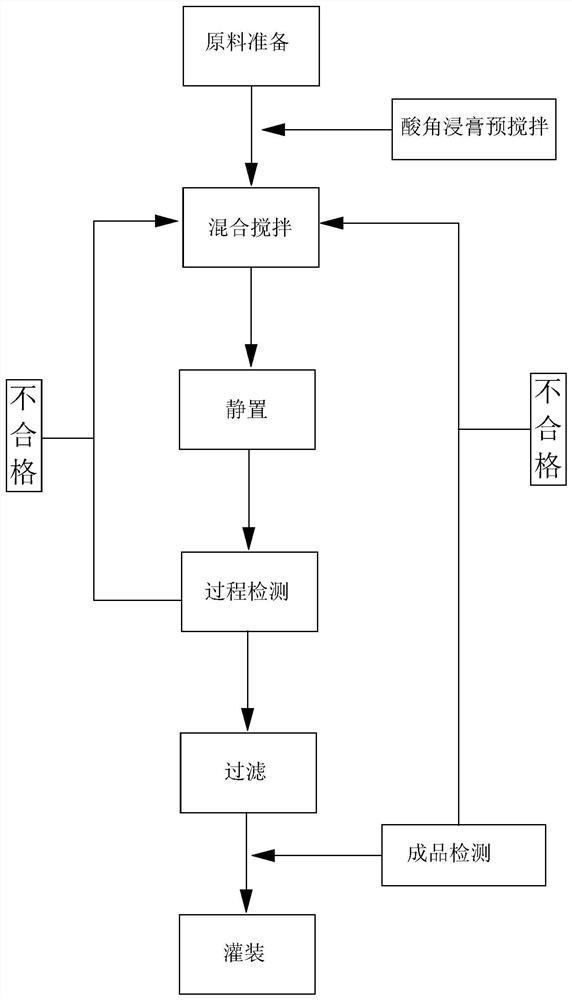

[0040] refer to figure 1

[0041] A kind of production technology of apricot liquid essence for tobacco comprises the steps:

[0042] Raw material preparation: Weigh 2kg of apricot juice concentrate, 5kg of tamarind extract, 3kg of apple juice powder, 3kg of peach fruit powder, 25kg of ethanol, 5kg of propylene glycol, 2kg of deionized water, 2kg of strawberry acid, 0.15kg of menthol, and antioxidants according to the formula 1kg and preservative 1kg, spare;

[0043] Weigh 1-2 times the ethanol solution of tamarind extract, and pre-stir the tamarind extract and ethanol solution evenly, and set aside; mixing and stirring: add the prepared raw materials and premix to the stirring device, set the stirring The mixing temperature is set at 45°C-85°C, the stirring speed is 1500rpm-2800rpm, and the stirring time is 30-50min; after the stirring is completed, the uniformly stirred liquid flavor mixture is left to stand for 3-5h;

[0044] In-process inspection: Sampling the homogeneous...

Embodiment 2

[0047] refer to figure 1

[0048] Raw material preparation: weigh 5kg of apricot juice concentrate, 6kg of tamarind extract, 6kg of apple juice powder, 6kg of peach fruit powder, 30kg of ethanol, 7kg of propylene glycol, 4kg of deionized water, 3kg of strawberry acid, 0.17kg of menthol, and antioxidants according to the formula. 1.5kg and preservative 1.5kg, spare;

[0049] Weigh 1-2 times the ethanol solution of tamarind extract, and pre-stir the tamarind extract and ethanol solution evenly, and set aside; mixing and stirring: add the prepared raw materials and premix to the stirring device, set the stirring The mixing temperature is set at 45°C-85°C, the stirring speed is 1500rpm-2800rpm, and the stirring time is 30-50min; after the stirring is completed, the uniformly stirred liquid flavor mixture is left to stand for 3-5h;

[0050] In-process inspection: Sampling the homogeneously mixed liquid flavor mixture, testing its physical and chemical indicators and aroma and fra...

Embodiment 3

[0053] refer to figure 1

[0054] Raw material preparation: weigh 8kg of apricot juice concentrate, 7kg of tamarind extract, 9kg of apple juice powder, 9kg of peach fruit powder, 30kg of ethanol, 9kg of propylene glycol, 6kg of deionized water, 4kg of strawberry acid, 0.19kg of menthol, and antioxidants according to the formula. 2kg and preservative 2kg, spare;

[0055] Weigh 1-2 times the ethanol solution of tamarind extract, and pre-stir the tamarind extract and ethanol solution evenly, and set aside; mixing and stirring: add the prepared raw materials and premix to the stirring device, set the stirring The mixing temperature is set at 45°C-85°C, the stirring speed is 1500rpm-2800rpm, and the stirring time is 30-50min; after the stirring is completed, the uniformly stirred liquid flavor mixture is left to stand for 3-5h;

[0056] In-process inspection: Sampling the homogeneously mixed liquid flavor mixture, testing its physical and chemical indicators and aroma and fragran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com