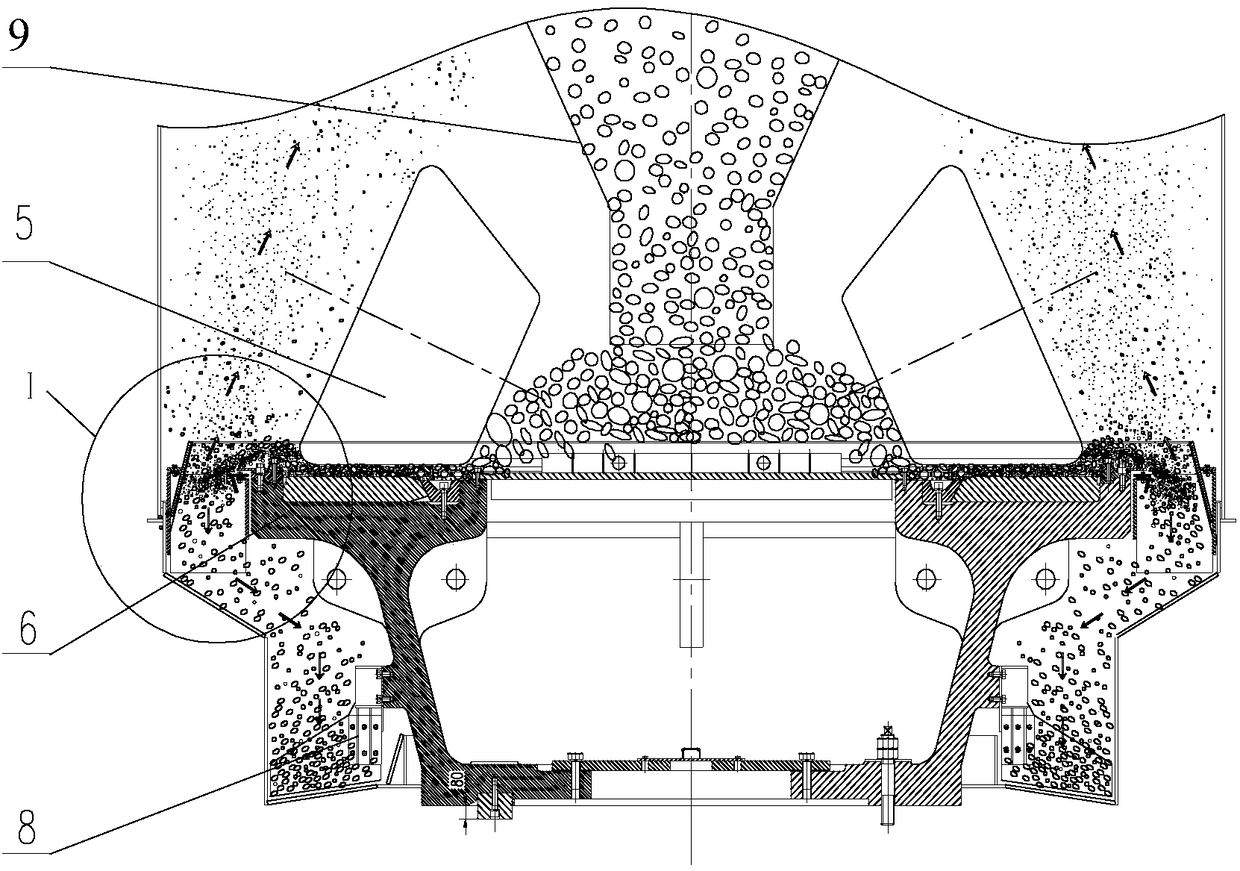

Air ring structure of a vertical roller mill

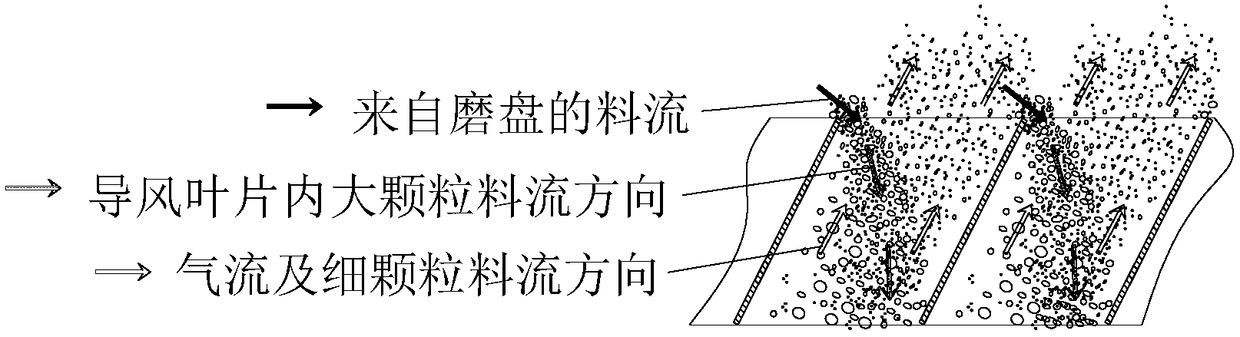

A vertical roller mill and air ring technology, which is applied in grain processing and other directions, can solve the problems of high air speed requirements, low sorting efficiency, and large wind resistance in the air ring, and achieve reduced powder concentration, good uniformity, and wind speed gradient. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the content, features and effects of the present invention, the following embodiments are given as examples, and detailed descriptions are as follows with accompanying drawings:

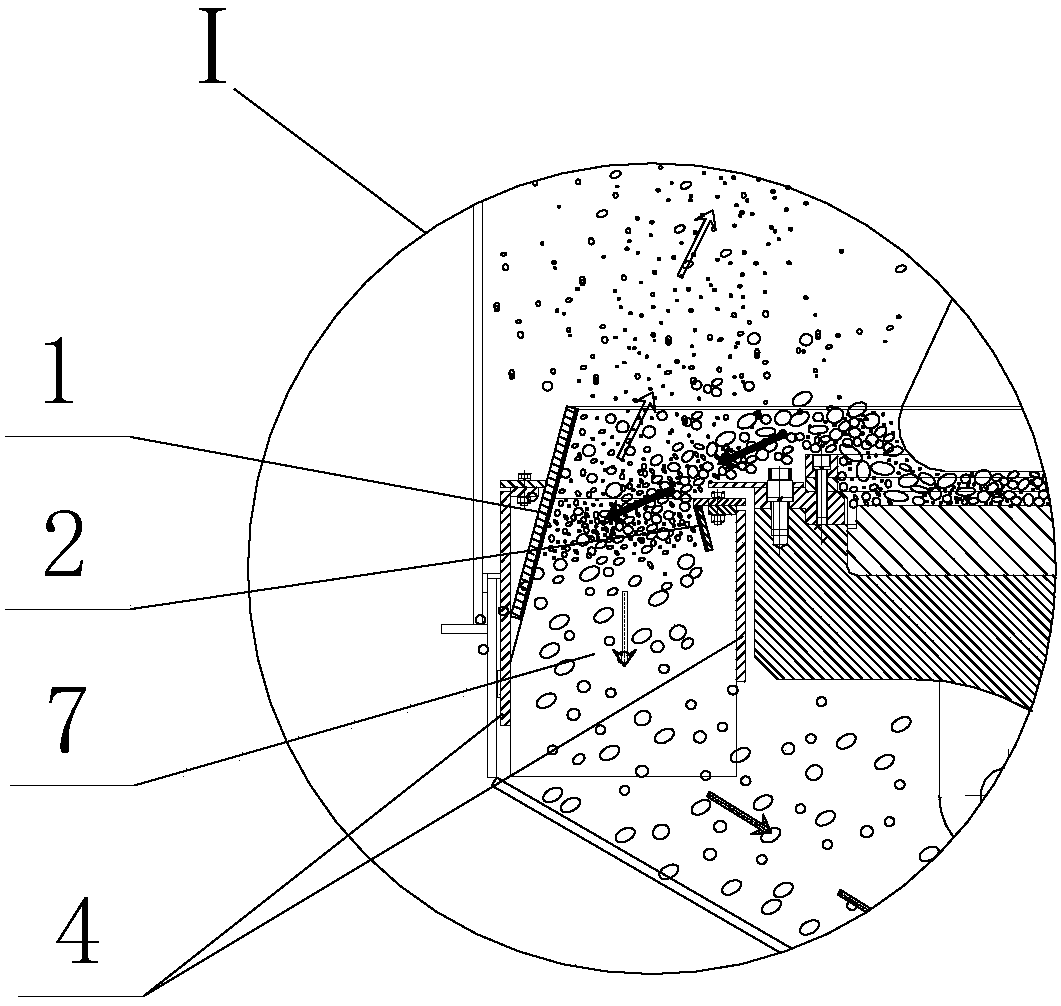

[0027] See Figure 5-Figure 7 . An air ring structure of a vertical roller mill includes an air ring outer ring 1, an air ring inner ring 2 and an air guide body 3. A plurality of the air guide bodies 3 are fixed between the air ring outer ring 1 and the air ring inner ring 2. The air guiding body 3 is composed of a horizontal cover 3-1, a first air guiding plate 3-2 and a second air guiding plate 3-3. The horizontal cover 3-1, the first wind deflector 3-2 and the second wind deflector 3-3 are connected end to end in turn to form the wind deflector 3 with a triangular cross section. In this embodiment, the horizontal cover 3-1, the first wind deflector 3-2 and the second wind deflector 3-3 are connected by welding. The horizontal cover plate 3-1 and the first ai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com