Method and equipment for automatic separation and oiling of blanks and method for manufacturing water cup liner

A technology of automatic separation and blanking, which is applied in the direction of manufacturing tools, metal processing equipment, forming tools, etc., can solve the problems of increasing product production costs, increasing labor costs, low production efficiency, etc., to improve production efficiency, reduce labor intensity, The effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

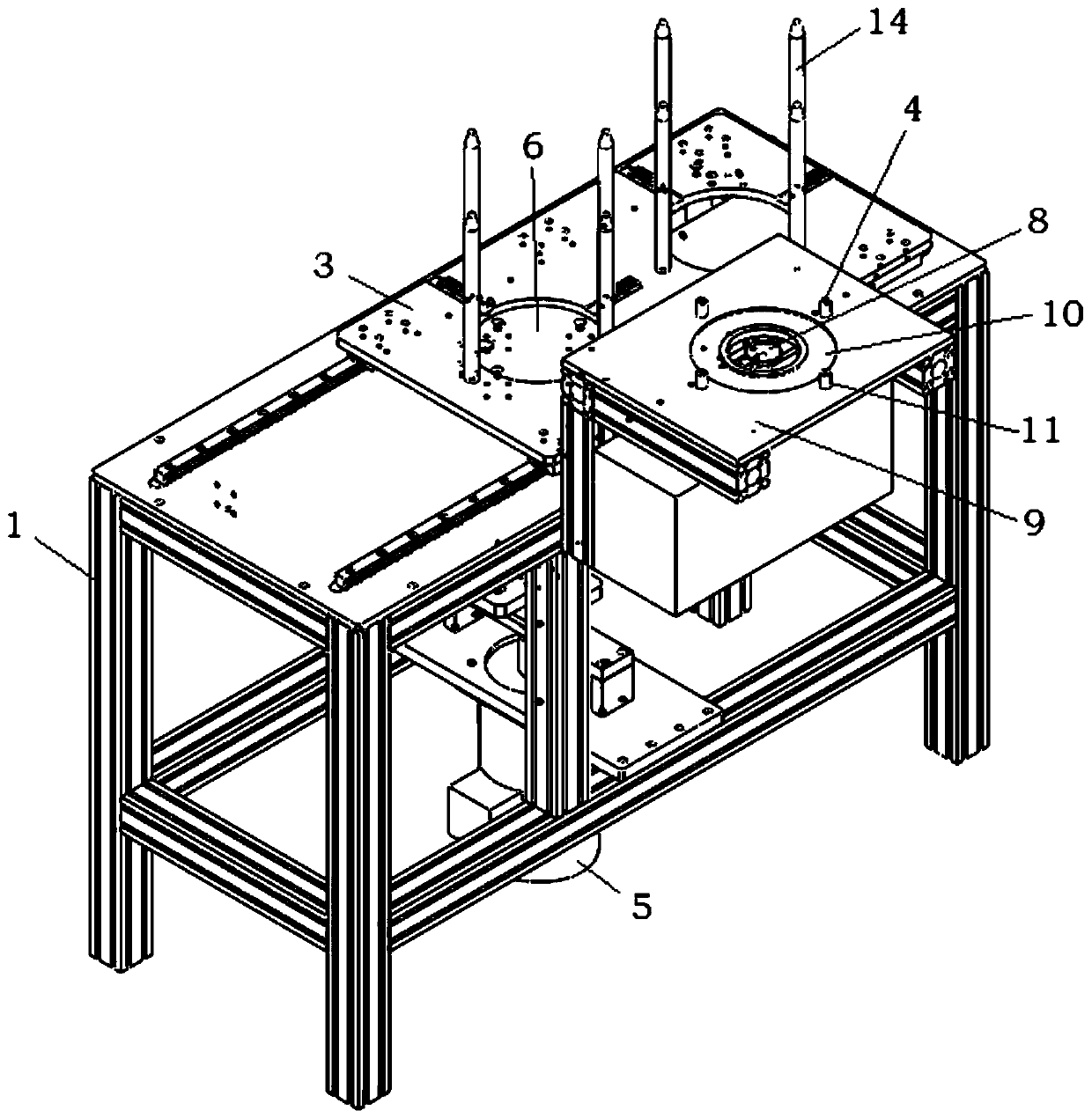

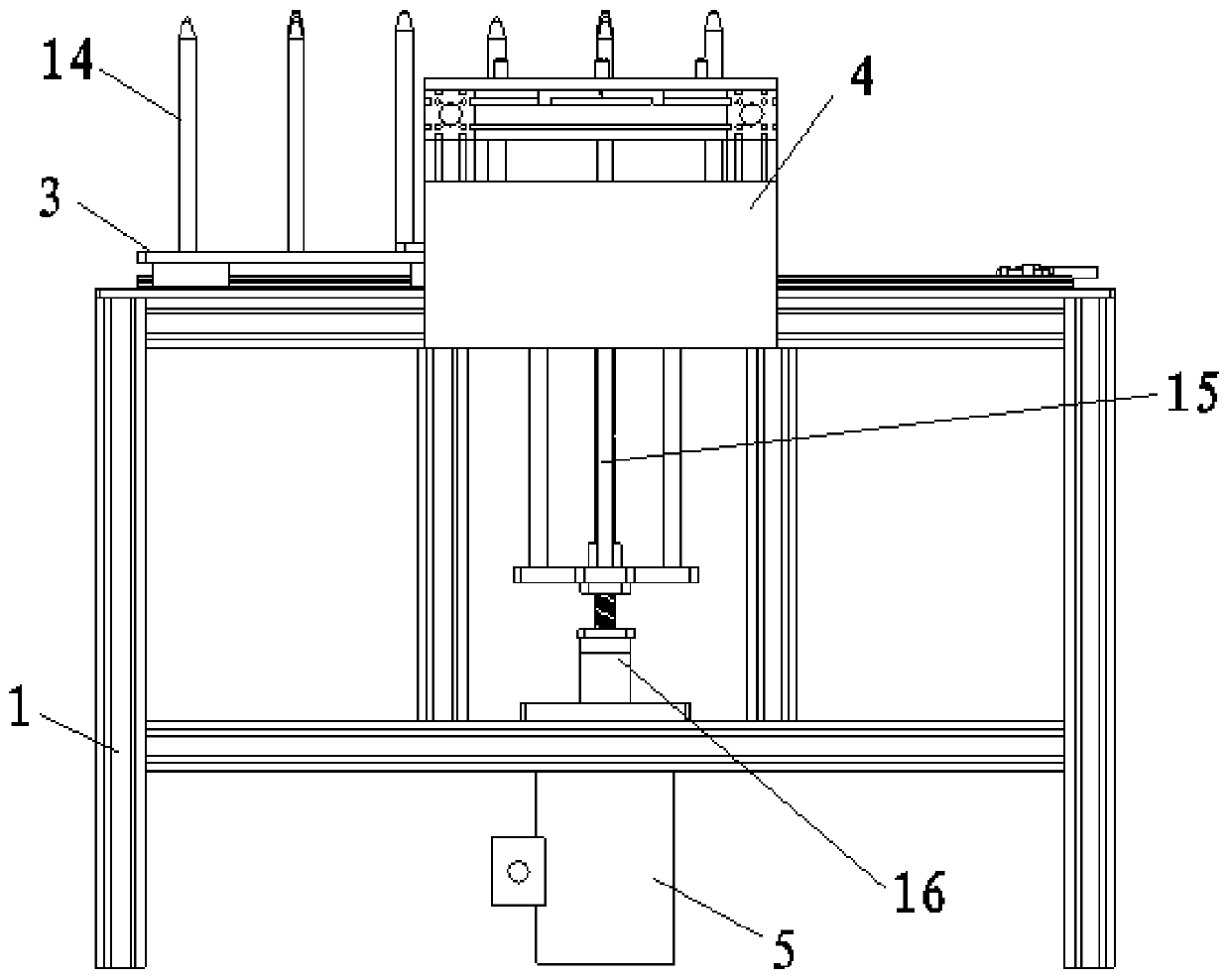

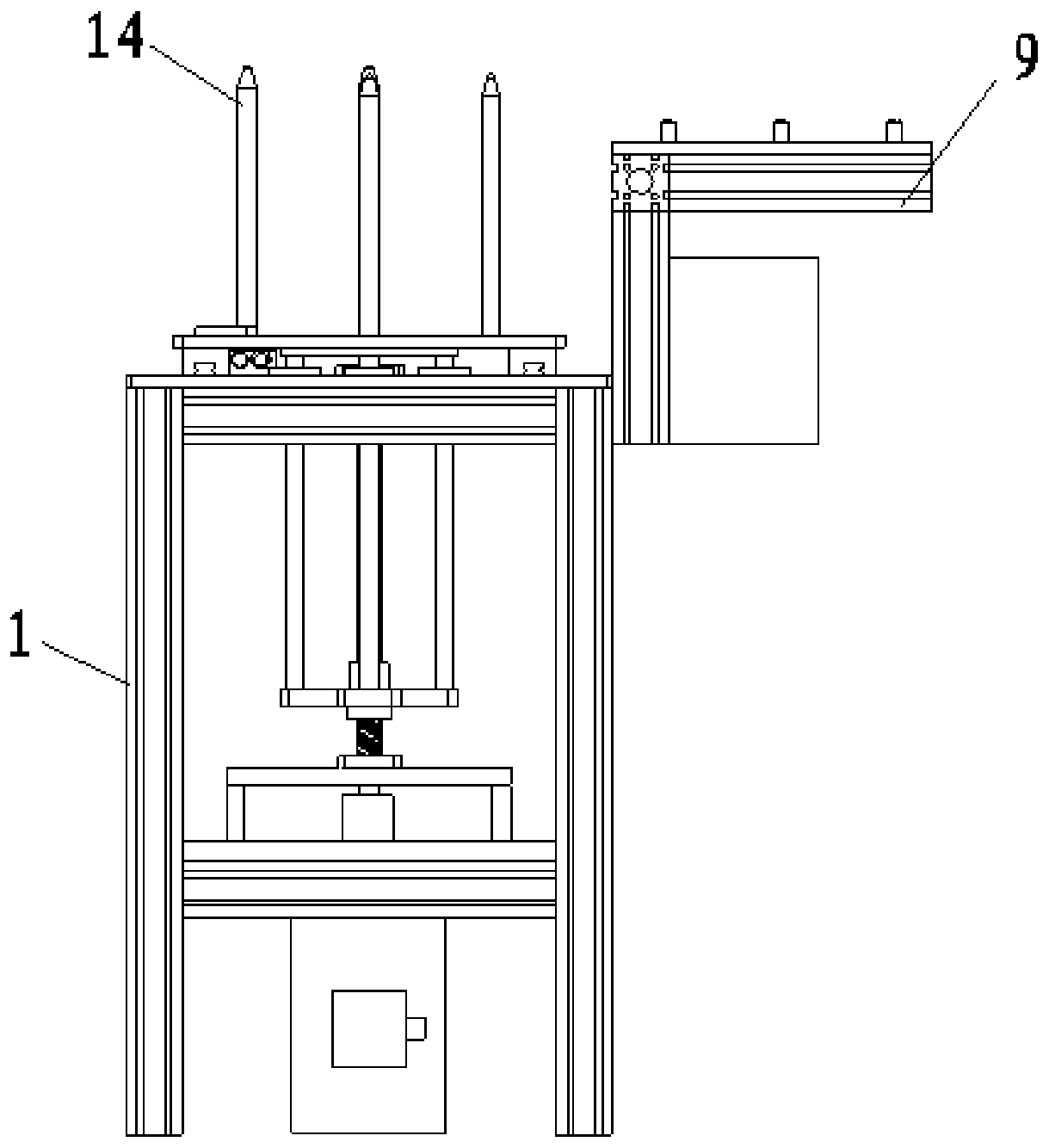

[0049] The invention provides a method for automatic separation and oiling of material sheets, which comprises the following steps:

[0050] The jacking station is set on the slide table slidingly connected with the frame;

[0051] Stack multiple blanks into a stack and place them above the ejecting station;

[0052] Lift up a stack of blanks located above the jacking station through the jacking device installed on the frame;

[0053] Whenever the top sheet in a stack of sheets is pushed to the grabbing station, move the current sheet at the top to the oiling station;

[0054] Carry out oiling treatment to the current sheet located on the oiling station through the oiling device;

[0055] Transfer the current sheet after oiling treatment to the next process;

[0056] Repeat the above steps of jacking up, grabbing, oiling, and transferring to the next process until a stack of blanks is transferred to the next process.

[0057] Below, the process of automatically separating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com