Filter cleaner base shell mould

A filter and shell technology is applied in the field of die-casting molds for filter base shells, which can solve the problems of low production efficiency and high cost, and achieve the effects of high production efficiency, low cost, and reduced holding force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

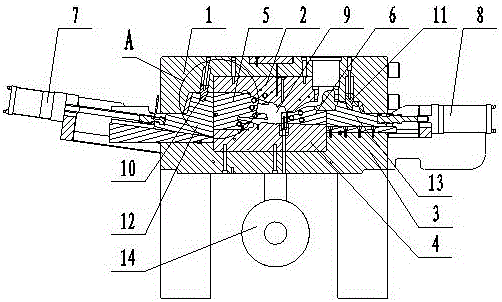

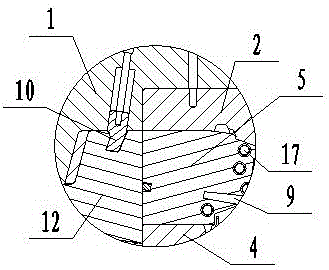

[0024] Embodiment one: combined with attached figure 1 and 2 , a filter base shell mold, comprising an upper mold frame 1, an upper mold core 2 arranged in the upper mold frame 1, a lower mold frame 3 and a lower mold core 4 arranged in the lower mold frame 3, the upper mold frame 1 is connected with the lower mold frame 3, on the left and right sides of the mould, between the upper mold core 2 and the lower mold core 4, there are respectively a left slider 5 and a right slider 6, and the ends of the left slider 5 and the right slider 6 The part is respectively provided with a left oil cylinder 7 and a right oil cylinder 8, and the combination of the upper mold core 2, the lower mold core 4, the left slider 5 and the right slider 6 forms the die-casting cavity 9 of the filter base shell, and the upper mold frame 1 is set There is a left side slanting block 10 suitable for the left slider 5 and a right side slanting block 11 suitable for the right slider 6. Near the die-castin...

Embodiment 2

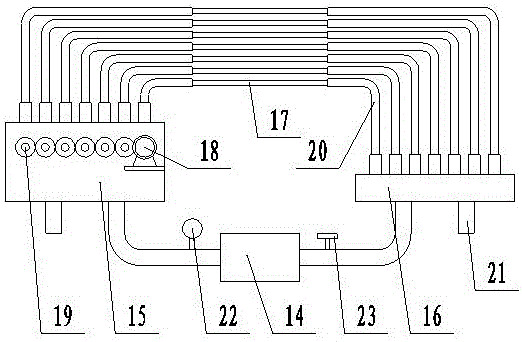

[0025] Embodiment two, combined with figure 1 , 2, 3, 4, 6, a filter base shell mold, including an upper mold frame 1, an upper mold core 2 arranged in the upper mold frame 1, a lower mold frame 3 and a lower mold arranged in the lower mold frame 3 Core 4, the upper mold frame 1 is connected with the lower mold frame 3, on the left and right sides of the mould, between the upper mold core 2 and the lower mold core 4, a left slider 5 and a right slider 6 are respectively provided, and the left slider 5 and the The end of the right slider 6 is respectively provided with a left oil cylinder 7 and a right oil cylinder 8, and the upper mold core 2, the lower mold core 4, the left slider 5 and the right slider 6 are combined to form the die-casting cavity 9 of the filter base shell , the upper mold frame 1 is provided with a left side slanting block 10 suitable for the left slider 5 and a right side slanting block 11 suitable for the right slider 6, near the die-casting cavity 9, t...

Embodiment 3

[0026] Embodiment three, combined with the attached figure 1 , 2 , 3, 5 and 6, a filter base housing mold, including an upper mold frame 1, an upper mold core 2 arranged in the upper mold frame 1, a lower mold frame 3 and a lower mold arranged in the lower mold frame 3 Core 4, the upper mold frame 1 is connected with the lower mold frame 3, on the left and right sides of the mould, between the upper mold core 2 and the lower mold core 4, a left slider 5 and a right slider 6 are respectively provided, and the left slider 5 and the The end of the right slider 6 is respectively provided with a left oil cylinder 7 and a right oil cylinder 8, and the upper mold core 2, the lower mold core 4, the left slider 5 and the right slider 6 are combined to form the die-casting cavity 9 of the filter base shell , the upper mold frame 1 is provided with a left side slanting block 10 suitable for the left slider 5 and a right side slanting block 11 suitable for the right slider 6, near the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com