Surface treatment methods of marine engineering materials

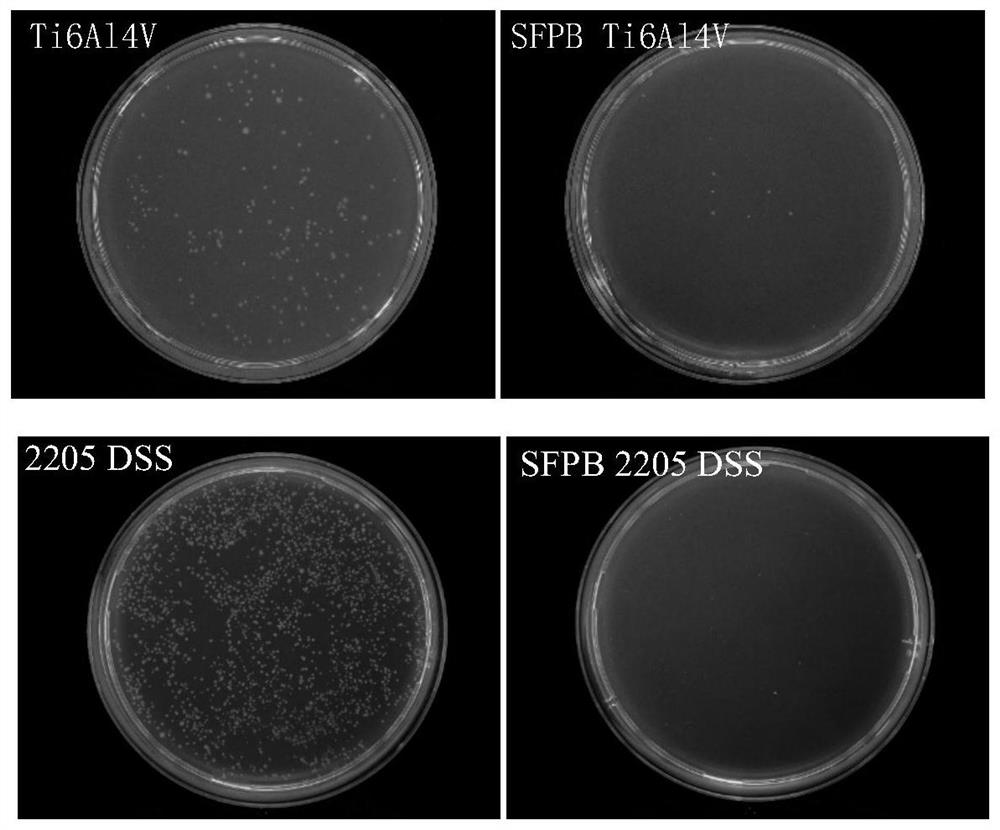

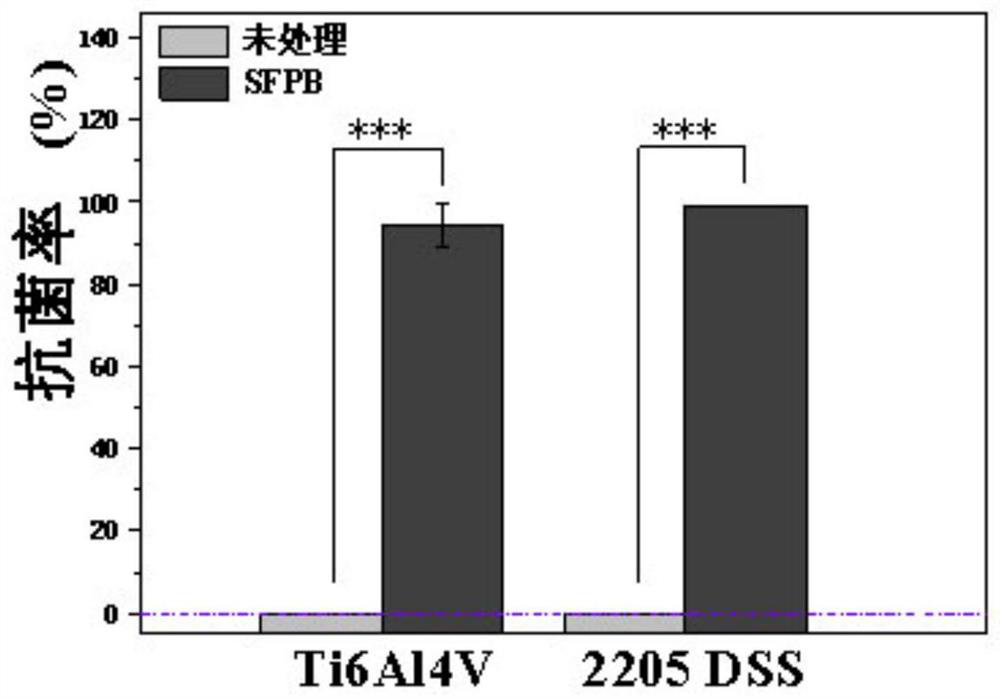

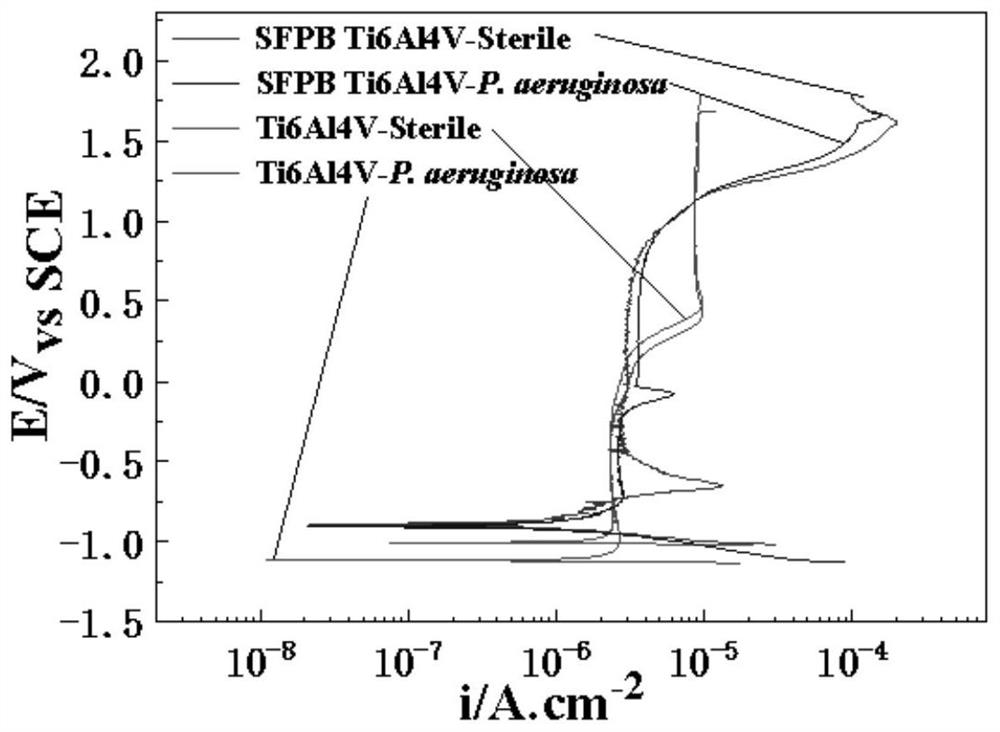

A technology for marine engineering and surface treatment, applied in the field of marine engineering materials, can solve the problems of destroying the marine ecological environment, short service life of anti-corrosion coatings, poor corrosion resistance, and poor weather resistance, so as to achieve enhanced microbial corrosion resistance and improved antimicrobial resistance. Corrosion performance, effect of improving antibacterial performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053]Surface treatment method of marine engineering materials, including the following steps:

[0054]Provides α phase -al particle size of 30 microns -60 micron2O3The ocean engineering metal workpiece to be treated, the alpha phase -al2O3It is dried in an oven at a temperature of 50 ° C; wherein the marine engineering metal workpiece is a workpiece with metal surface of marine engineering;

[0055]Surface bombardment of the marine engineering metal workpiece is used in ultraponic particle bombardment technology, and the surface bombardment process, regulation: the injection carrier gas pressure is 1 MPa-2.5MPa, the bombardment time is 2S-30S / cm2The injection angle is 90 ° (vertical nozzle and sample), the distance from the nozzle and the sample is controlled at 30 mm to 40 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com