Method and devcie for making heat-insulation fireproof calcium silicate board

A technology of fireproof board and calcium silicate, which is applied in the manufacture of tools, ceramic molding machines, etc., can solve the problems of low heat resistance temperature, high mechanical strength, high volume density, etc., to improve high temperature performance, high activity, and reduce reaction temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

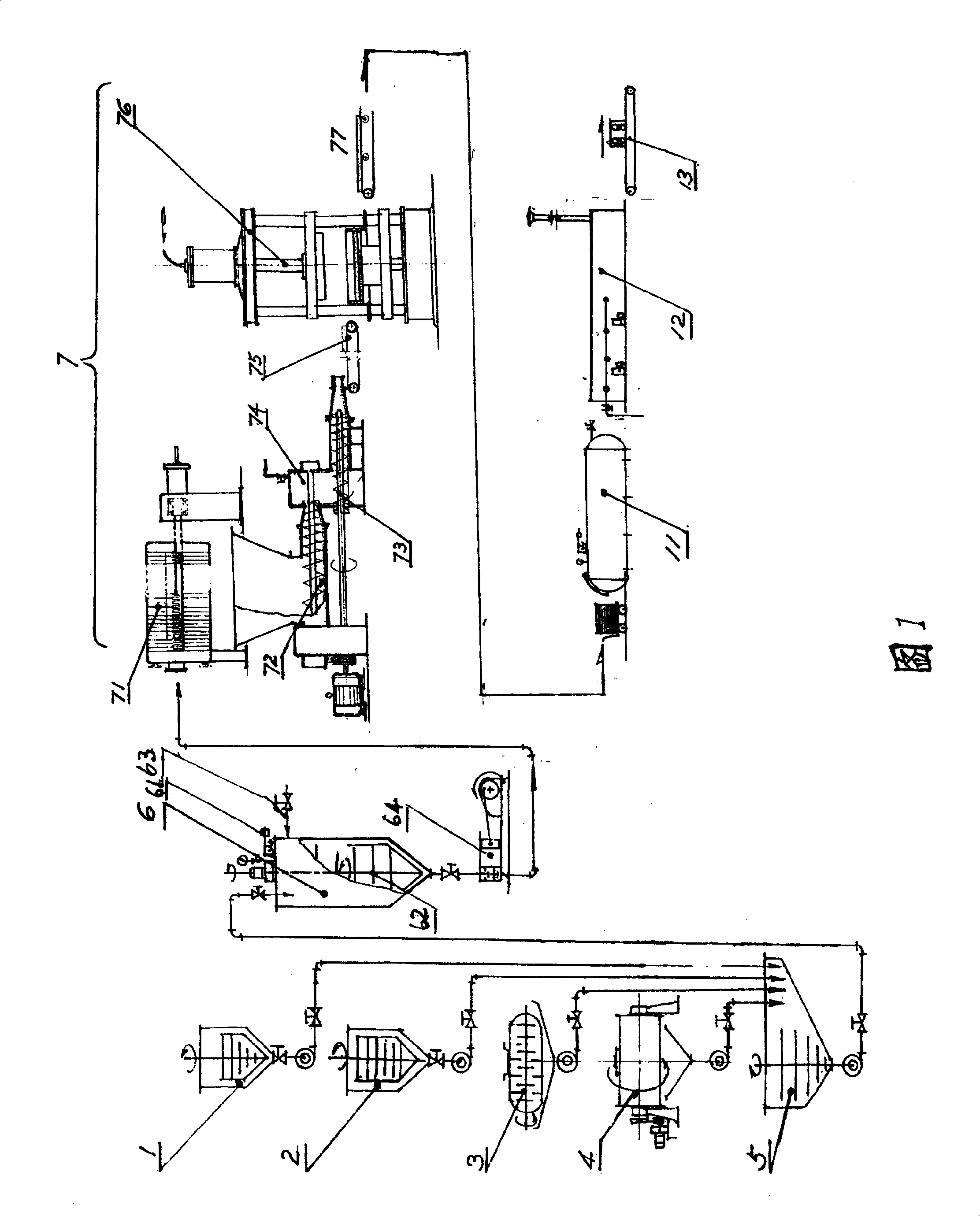

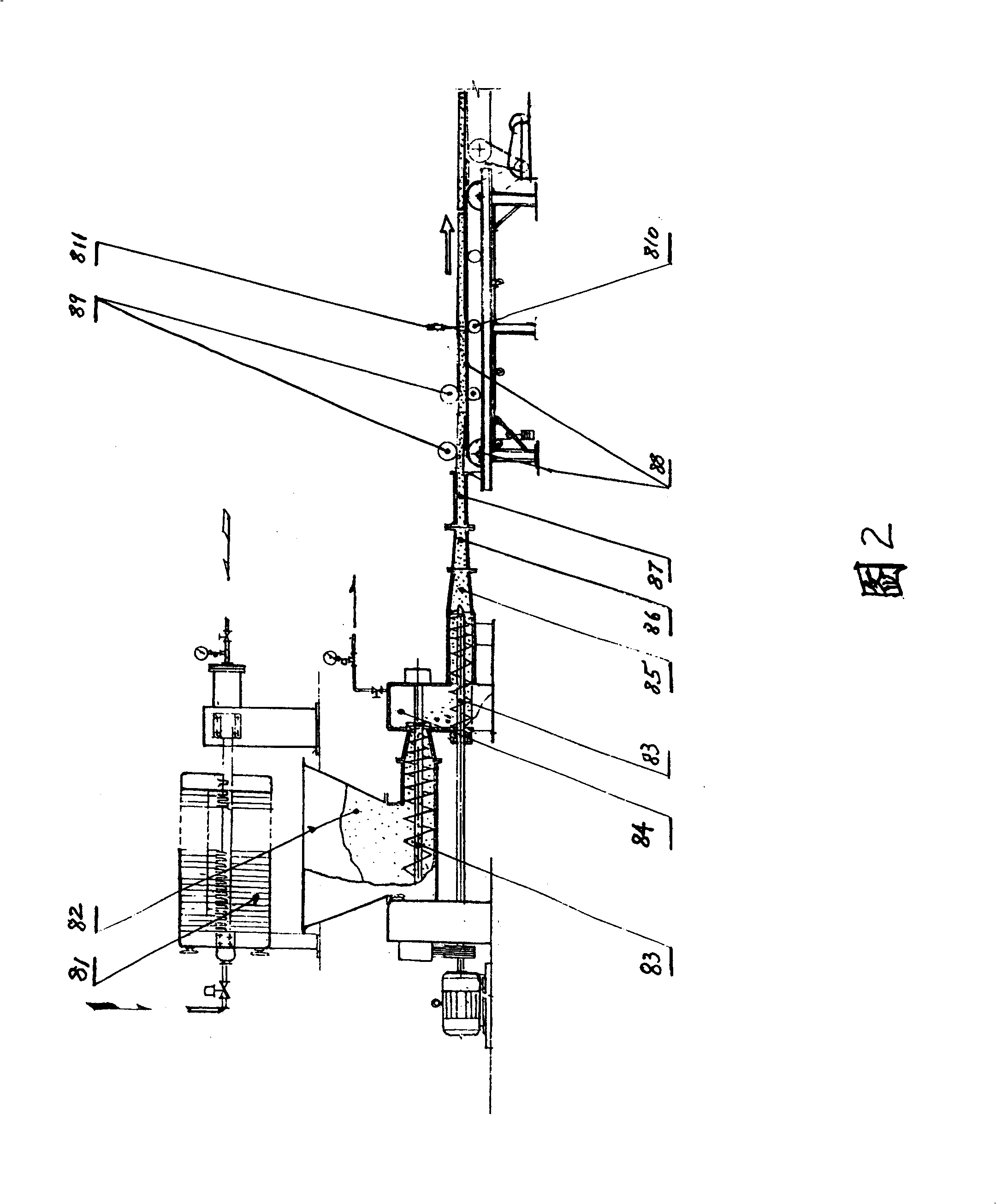

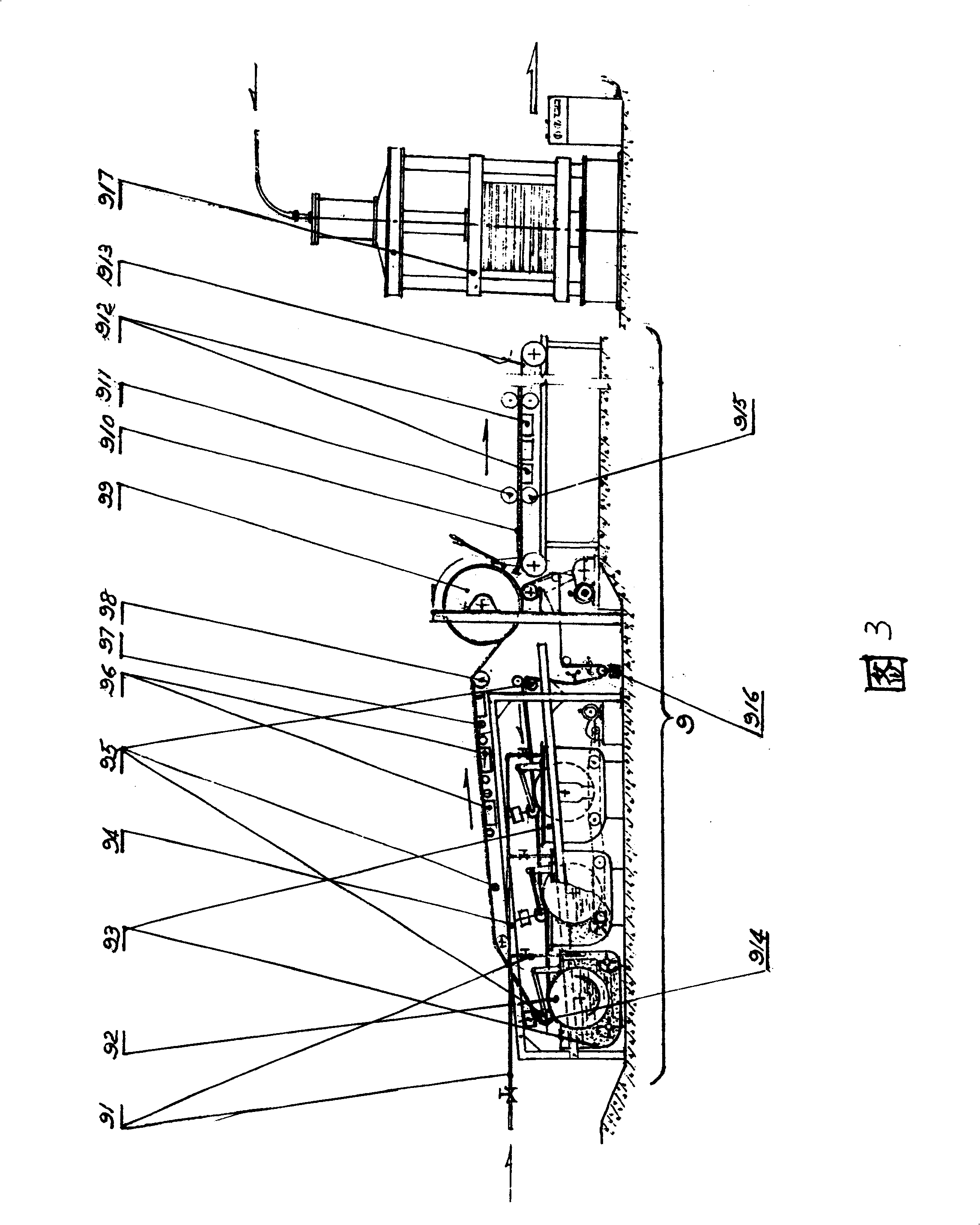

Method used

Image

Examples

Embodiment 1

[0066] Grind the quartz until it passes through a 60 μm sieve, and add 10% of the dispersed silica fume by weight of the siliceous raw material. Then add slaked lime powder with a CaO content of 72.2%, stir evenly, the Ca / Si=0.98 of the slurry, then add 2% of dry material weight dispersed hemp fiber and 5% wollastonite powder, and mix the uniform slurry Enter a sealed gelling tank with stirring, add water to water / material (weight ratio) = 3.1, stir at 120 rpm and heat with steam, at 120°C for 8 hours, then vent and cool down to normal pressure. Pump the material from the plunger pump to the plate and frame filter press to filter water until the water content is 52%, extrude the plate-shaped blank through the vacuum kneader, cut the appropriate blank and press it into a plate in the mold of the press. The size of the plate is 1004×504×27(mm), put the board on the car and send it into the steam curing kettle, ventilate and heat to 2.0MPa, and continue for 22 hours, then vent an...

Embodiment 2

[0068] Grind the quartz until all of it passes through a 30 μm sieve, add milk of lime with a CaO content of 69.4% (dry basis), stir well, and the Ca / Si=1.05 of the slurry. Add paper fiber with 5% weight of dry material, and add water to water / material (weight ratio) = 9.9, put it into the gelling tank, heat to 90°C with steam, and continue at 90°C to 96°C for 30 hours. The slurry is injected into a mold with a vacuum at the bottom, a large number of small holes are evenly distributed on the bottom plate of the mold, and felt cloth is spread on it. Turn on the vacuum to absorb water, until the material loses its fluidity, spread a felt on the material, use a round roller with a weight of about 100kg to roll on the felt until it is 22mm thick and the material is firm, remove the round roller and felt, and break the lower vacuum , use a suction cup to take out the plate and put it on the trolley. The size of the plate is 1020×520×22 (mm). The plate is steamed in the steam curing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com