Clamping and transporting manipulator

A technology of a manipulator and a clamping mechanism, applied in the field of manipulators, can solve the problem that the manipulator cannot meet the requirements of safe clamping, and achieve the effects of improving clamping and handling efficiency, ensuring aesthetics, and improving equipment safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

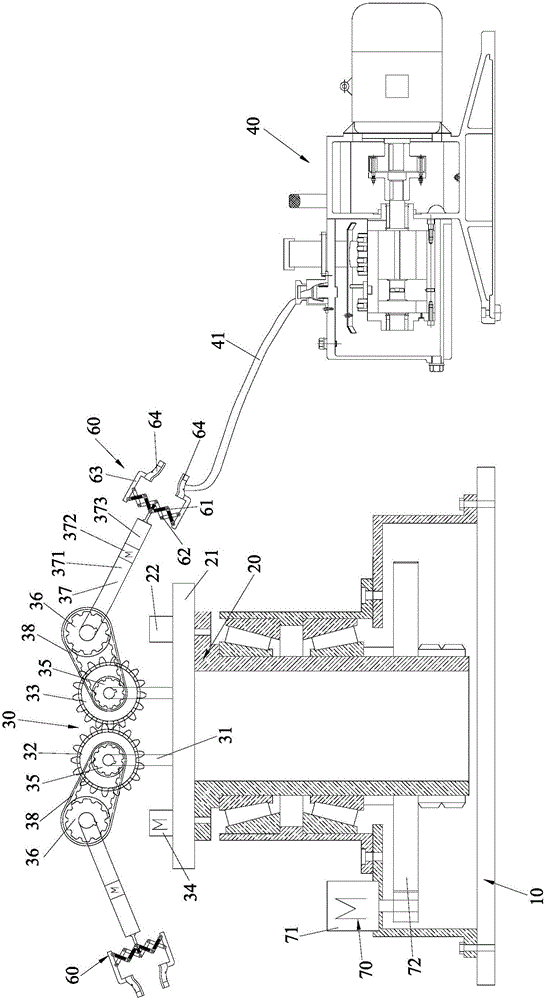

[0048] Please refer to Figure 1 to Figure 5 As shown, it has shown the specific structure of the preferred embodiment of the present invention, including base 10, swivel base 20, dual arm mechanism 30, vacuum pump 40, finger sending mechanism 50, basic arc finger storehouse (not shown in the figure) Shown) and two clamping mechanisms 60.

[0049] The swivel base 20 is rotatably mounted on the base 10, the base 10 is provided with a drive mechanism 70, the drive mechanism 70 drives the swivel base 20 to rotate back and forth, the top of the swivel base 20 is provided with a support plate 21, specifically In other words, the drive mechanism 70 includes a stepping motor 71 and a spur gear pair 72, the stepping motor 71 drives the swivel base 20 to rotate through the spur gear pair 72, and the stepping motor 71 is located on the base 10 , the spur gear pair 72 is located inside the base 10 , and the swivel base 20 is rotatably mounted on the base 10 through the bearing 11 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com