Seamless splicing method for conveying belt

A technology of seamless joints and conveyor belts, which is applied in the field of seamless joints of conveyor belts, can solve problems such as surface roughness of conveyor belts, reduced strength of conveyor belts, long operating time, etc., achieve good lateral stability, improve adaptability, reduce The effect of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The conveyor belt in this embodiment has a one-cloth-one-glue structure, wherein the glue layer is polyvinyl chloride, and when the conveyor belt is connected, the steps are as follows:

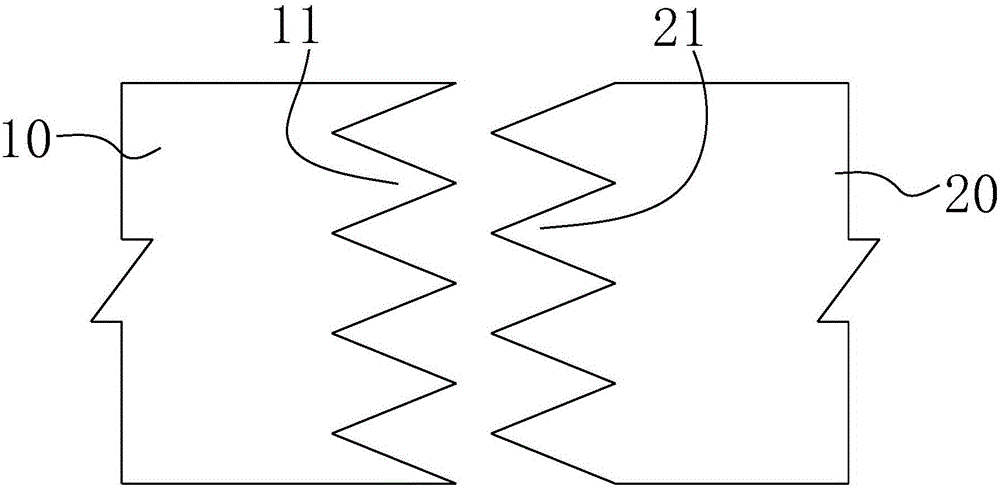

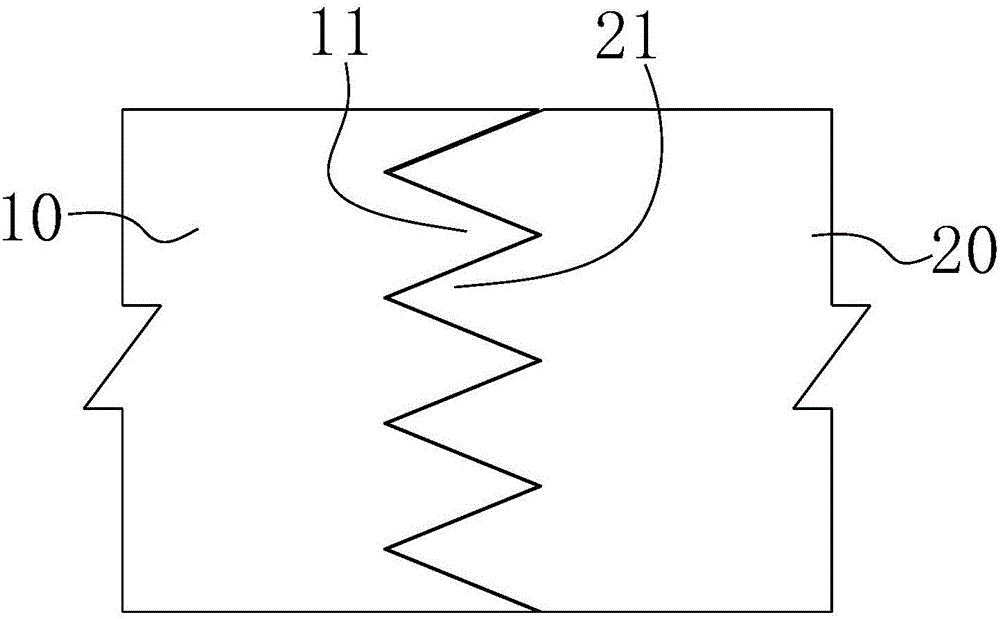

[0028] Punching, the first connecting end 10 of the conveyor belt is cut out a plurality of first convex teeth 11 arranged in a zigzag shape, and the second joint end 20 is cut out a plurality of second convex teeth 21 arranged in a zigzag shape. The tooth top of the tooth 11 corresponds to the tooth groove of the second convex tooth 21 , and the tooth groove of the first convex tooth 11 corresponds to the tooth top of the second convex tooth 21 .

[0029] In this embodiment, the first protruding teeth 11 and the second protruding teeth 21 are both triangular in shape.

[0030] Pre-connection, the first connection end and the second connection end are abutted, so that the first convex tooth and the second convex tooth are engaged with each other, and then the connection between the fir...

Embodiment 2

[0034] This embodiment is basically the same as Embodiment 1, the difference is that:

[0035] When the upper heating plate and the lower heating plate pressurize the junction of the first protruding tooth and the second protruding tooth, the pressure is 0.3 MPa.

[0036] When heating the upper heating plate and the lower heating plate, the temperature was 180° C., and the temperature was lowered after heating for 25 minutes.

Embodiment 3

[0038] The conveyor belt in this embodiment has a two-cloth-two-glue structure, and the glue layer is polyvinyl chloride. When the conveyor belt is jointed, proceed as follows:

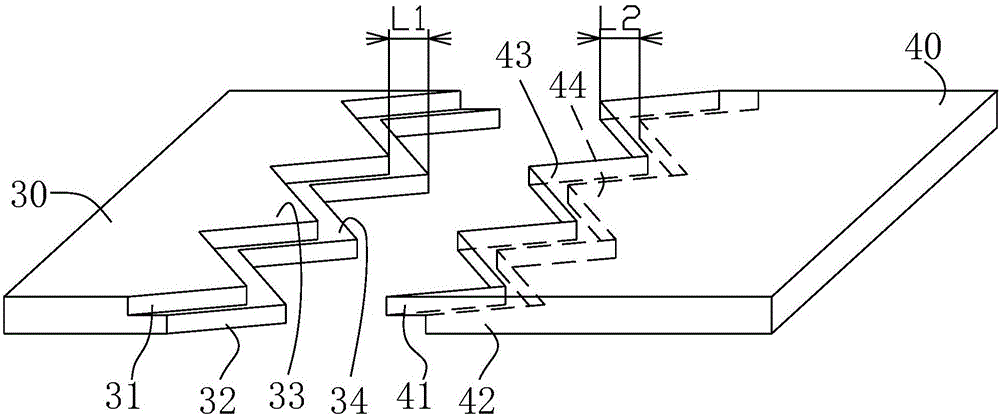

[0039] The first connection end 30 of the conveyor belt is stripped into two layers along the length direction of the conveyor belt, and each layer includes a cloth and a glue. For the convenience of description, the two layers of the first connection end 30 are respectively called For the first layer A31 and the second layer A32, the first layer A31 and the second layer A32 are respectively punched, the first protruding teeth 33 of the first layer A31 are arranged in a zigzag shape, and the second layer A31 The first protruding teeth 34 of A32 are arranged in a zigzag shape. There is a first distance L1 between the first protruding teeth 33 of the first layer A31 and the first protruding teeth 34 of the second layer A32 along the length direction of the conveyor belt.

[0040]Then the second connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com