Bogie of railway vehicle and axle-head power generation assembly of bogie

A technology for power generation devices and railway vehicles, which is applied to vehicle energy devices, bogies, railway car body components, etc., can solve problems such as adverse effects of vehicle design, occupying space above the bogie frame, and increasing height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

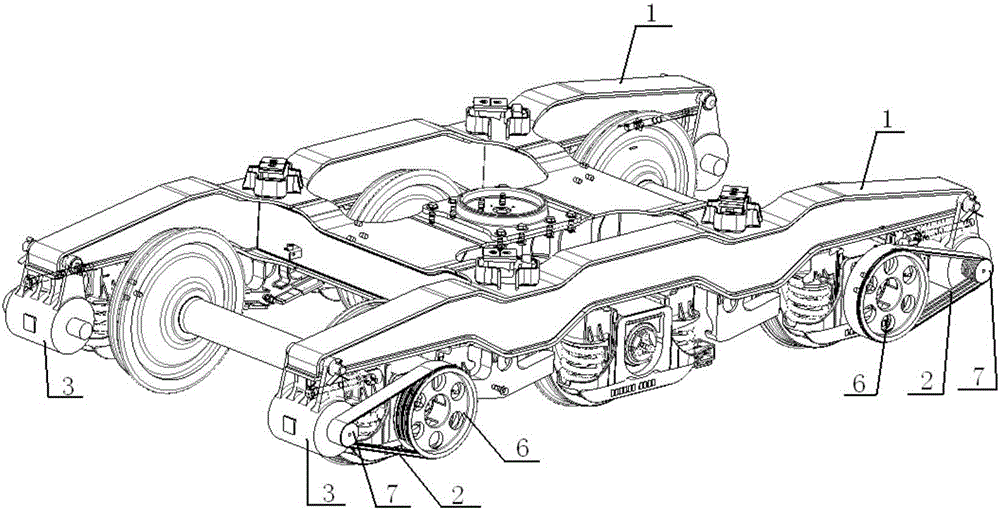

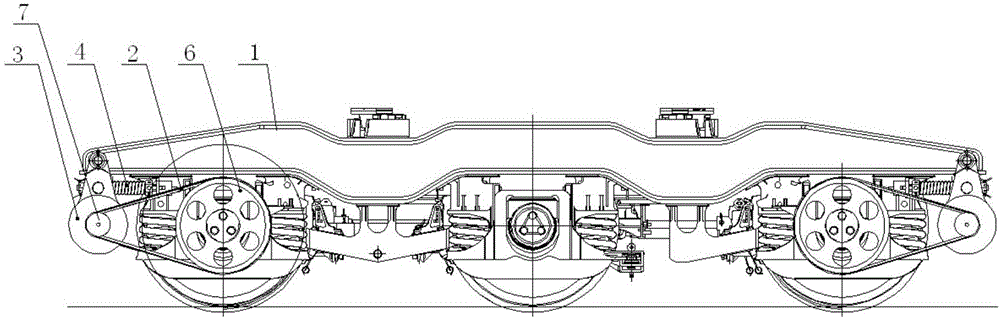

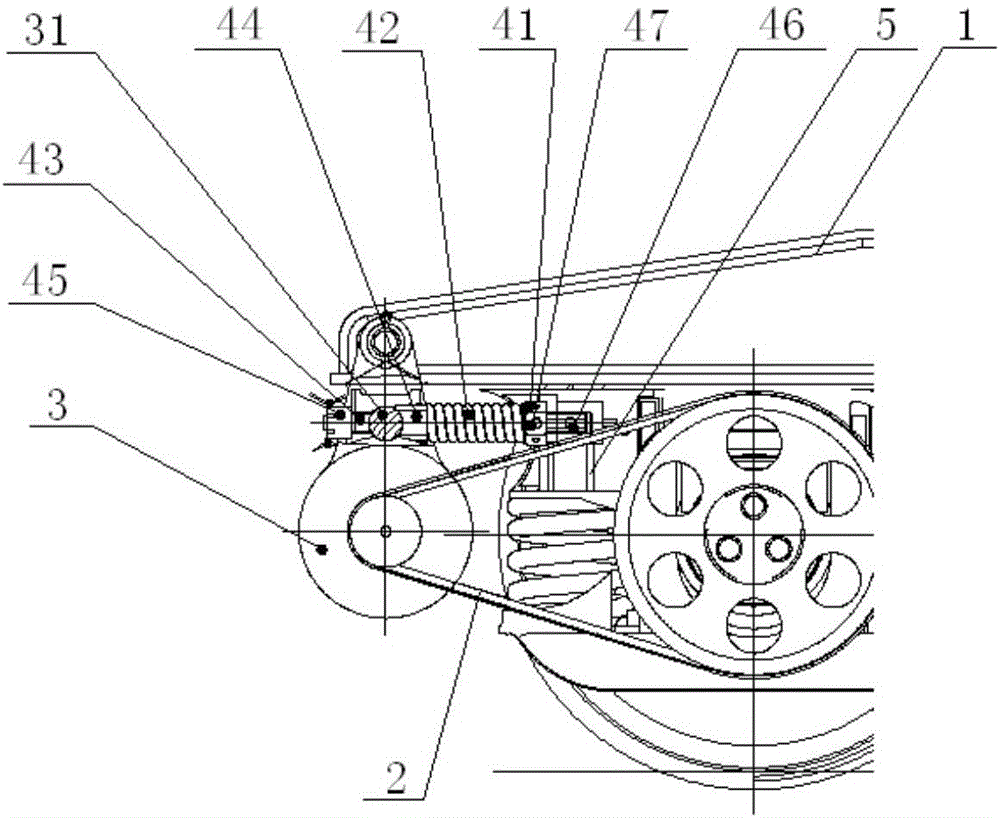

[0027] The present invention provides a bogie of a railway vehicle and a shaft end power generation device thereof. The shaft end power generation device is arranged under the bogie frame 1, which does not occupy the space above the frame 1. The structure is simple, and the space occupied is small. The structural influence of the frame 1 is small, and the optimization of vehicle design parameters can be realized.

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can accurately understand the technical solution of the present invention.

[0029] For the convenience of explanation, this article takes the running state of the railway vehicle as a reference to define the direction, and takes the direction parallel to the running direction as the longitudinal direction. In the longitudinal direction, the direction in front of the running direction is the front, and the direction opposite t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com