Coil conveying device of heat shrinkage film wrapping machine

A conveying device and coating machine technology, applied in the directions of packaging, wrapping paper, wrapping paper shrinkage, etc., can solve the problems that affect the appearance of products, increase the production cost of enterprises, decrease the yield rate of products, etc., achieve stable clamping, improve Productivity and avoidance of rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

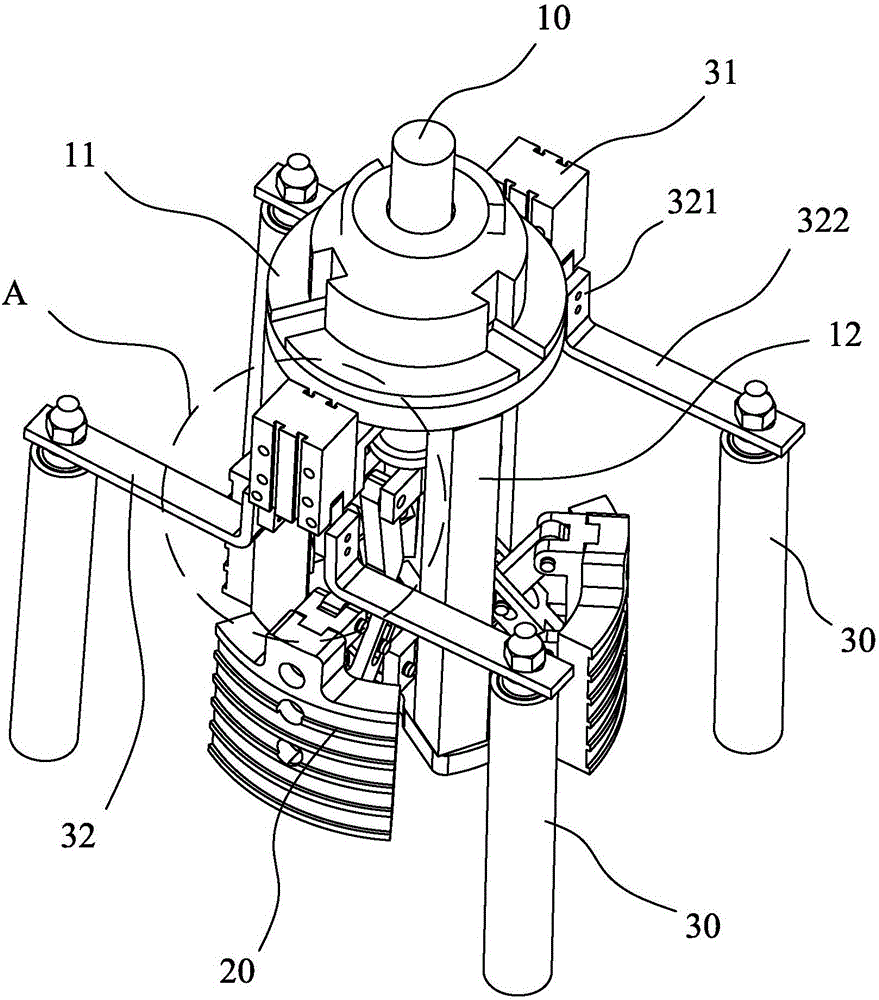

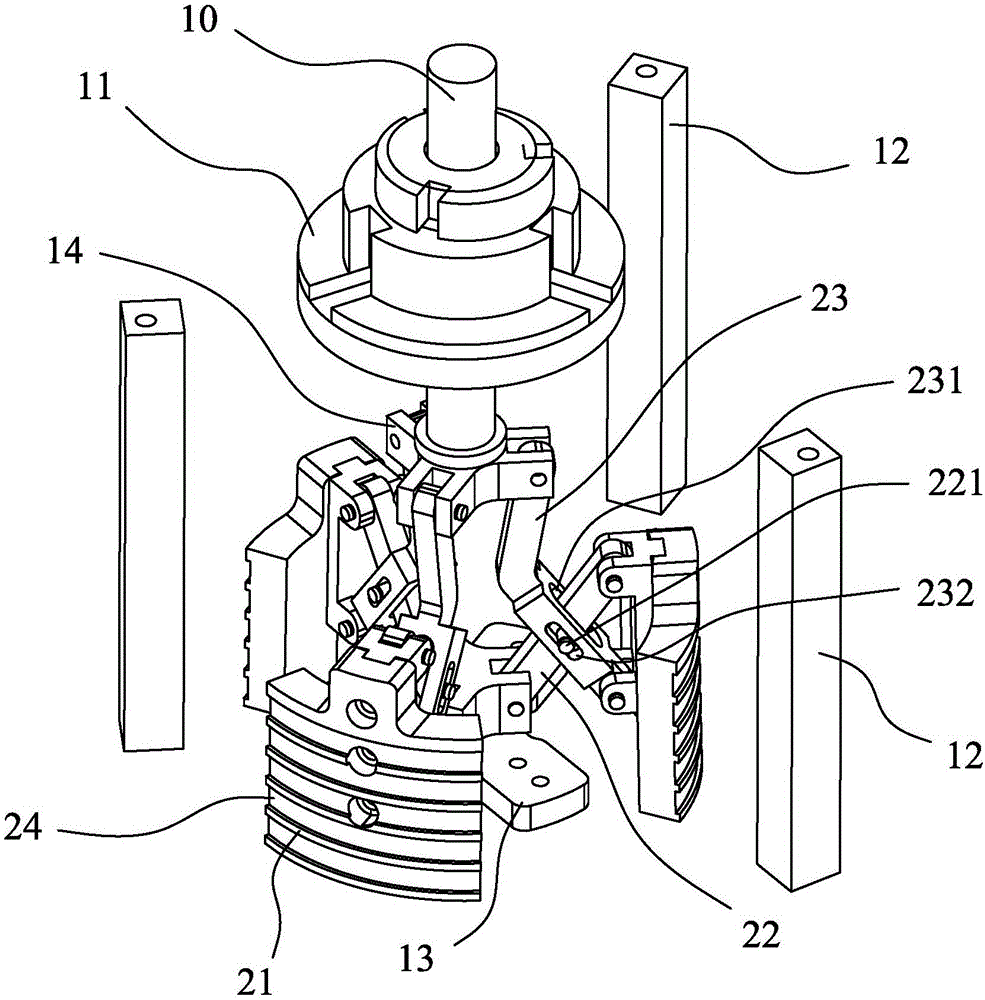

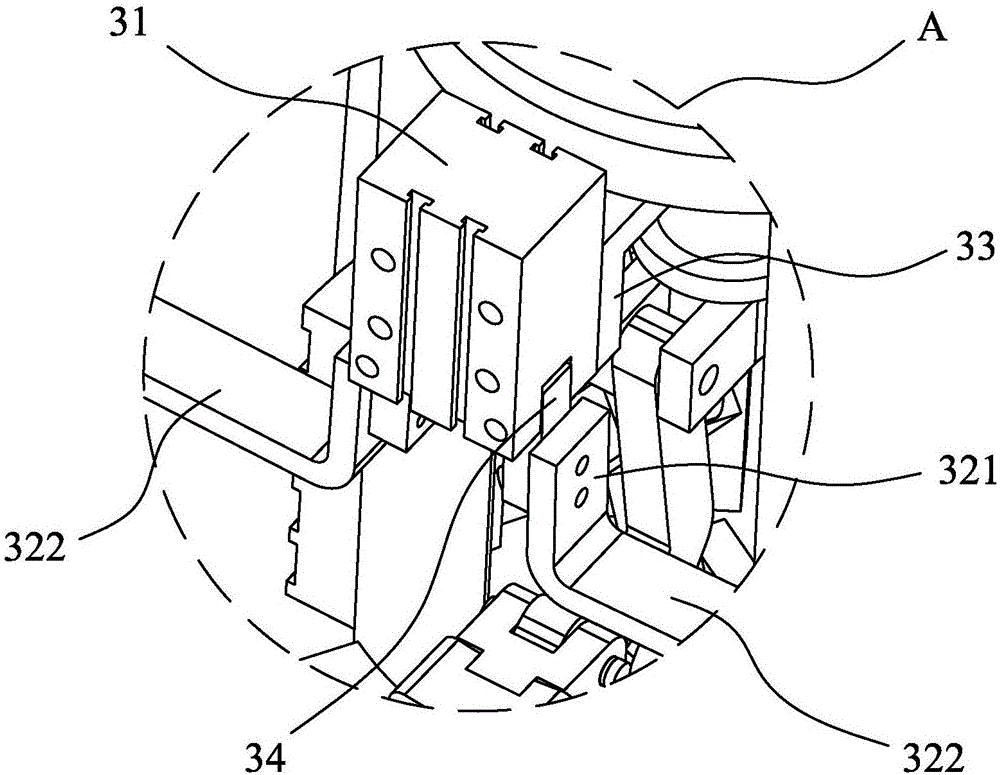

[0030] Please refer to Figure 1-3 As shown, a coil delivery device of a heat shrink wrapping machine includes a claw mechanism for clamping the inner circle of the coil and a clamping mechanism for clamping the outer circle of the coil. The claw mechanism includes a plurality of annular The distributed claws 20, the push rod 10 that drives each claw 20 to open and close in the radial direction, and the first drive element that drives the push rod 10 to move up and down, the clamping mechanism includes a plurality of rings distributed outside the claws 20 The clip bar 30 and the second driving element 31 that drives the clip bar 30 to flip open and close.

[0031] The claw mechanism also includes a push rod mounting seat 11, a claw connecting seat 14, a claw base 13 and a plurality of support rods 12 connected between the push rod mounting seat 11 and the claw base 13. The seat 11 is provided with a shaft hole that is compatible with the push rod 10, and the push rod 10 is mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com