Two-way shovel arm cavity assembled tray

An assembled and palletized technology, which is applied in the field of stacking and packaging, can solve the problems of unfavorable resource saving and unfavorable user cost, and achieve the effects of saving resources, increasing strength, and reducing use costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

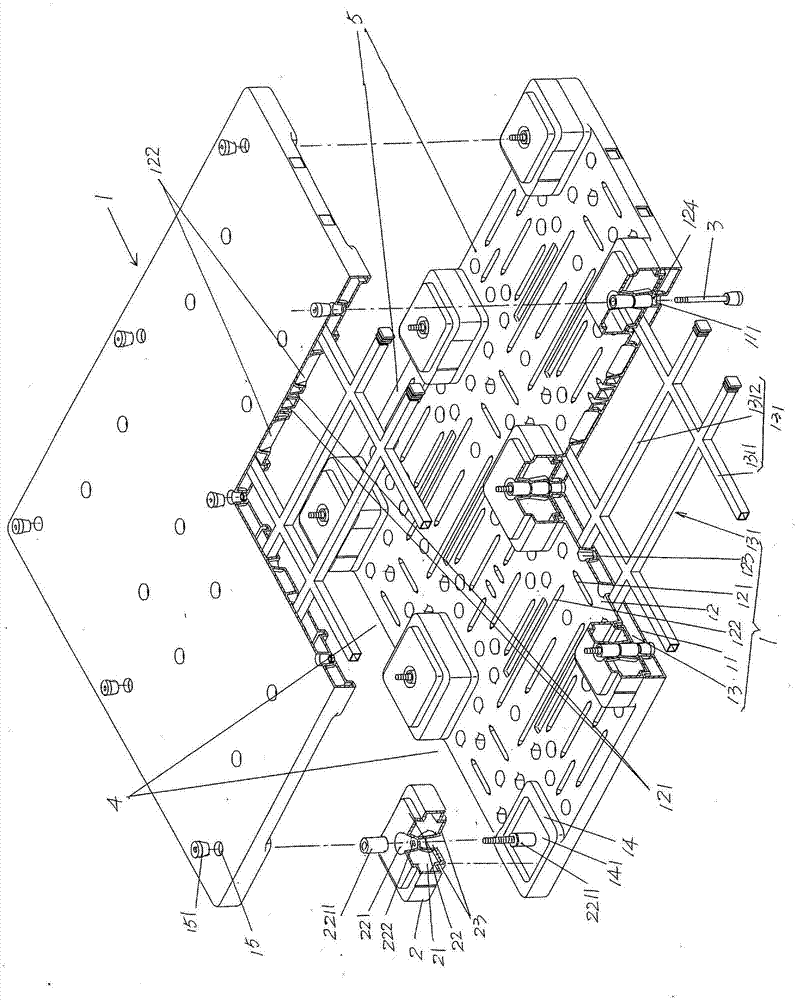

[0018] See figure 1 , showing a pair of blown and face-to-face trays each consisting of the upper panel 11 of the tray body and the lower panel 12 of the tray body and between the upper panel 11 of the tray body and the lower panel 12 of the tray body a tray with closed sides The tray body 1 of the body cavity 13, the blowing mentioned here refers to the blow molding by a blow molding machine through a mold. In this embodiment, the material of a pair of tray bodies 1 is high molecular weight and high strength polyoxyethylene ( The English abbreviation is: HMWHDPE).

[0019] As the technical gist of the technical solution provided by the present invention: a tray body metal reinforcing frame 131 is respectively embedded in the aforementioned tray body cavity 13 of the aforementioned pair of tray bodies 1, and a tray body lower panel 12 of the aforementioned pair of tray bodies 1 left, middle, and right ends of the opposite side of the figure 1 The position state shown is an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com