Method, device and system for processing glass cassettes

A processing method and cassette technology, which are applied in the directions of collaborative operation devices, storage devices, transportation and packaging, etc., can solve problems such as abnormal alarms, downtime of internal suspension equipment, and restricted storage directions, so as to improve work efficiency. Efficiency, the effect of reducing incentive labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] According to an embodiment of the present invention, a method embodiment of a glass cassette processing method is provided. It should be noted that the steps shown in the flow charts of the accompanying drawings can be executed in a computer system such as a set of computer-executable instructions , and, although a logical order is shown in the flowcharts, in some cases the steps shown or described may be performed in an order different from that shown or described herein.

[0044] Figure 5 It is a flowchart of a processing method for a glass cassette according to an embodiment of the present invention, such as Figure 5 As shown, the method includes the following steps:

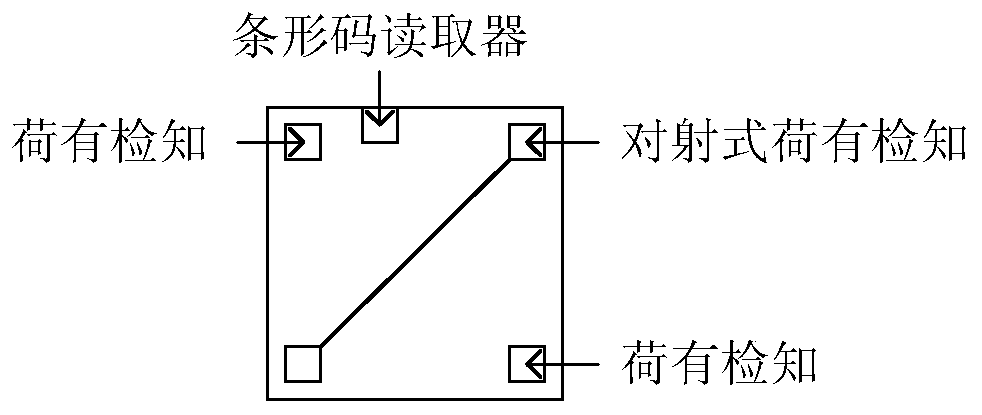

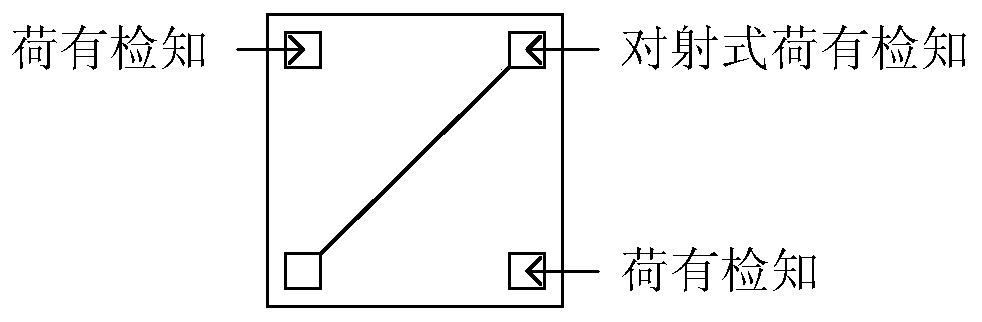

[0045] Step S502, when the glass cassette is detected in the first area of the inner suspension device, identify the placement direction of the glass cassette, where the placement direction includes: forward placement and reverse placement.

[0046] Specifically, the above-mentioned first area ma...

Embodiment 2

[0119] According to an embodiment of the present invention, an apparatus embodiment of an apparatus for processing a glass cassette is provided.

[0120] Figure 10 is a schematic diagram of a processing device for a glass cassette according to an embodiment of the present invention, such as Figure 10 As shown, the device includes:

[0121] The determining module 101 is configured to identify the placement direction of the glass cassette when the glass cassette is detected in the first area of the inner suspension device, wherein the placement direction includes: forward placement and reverse placement.

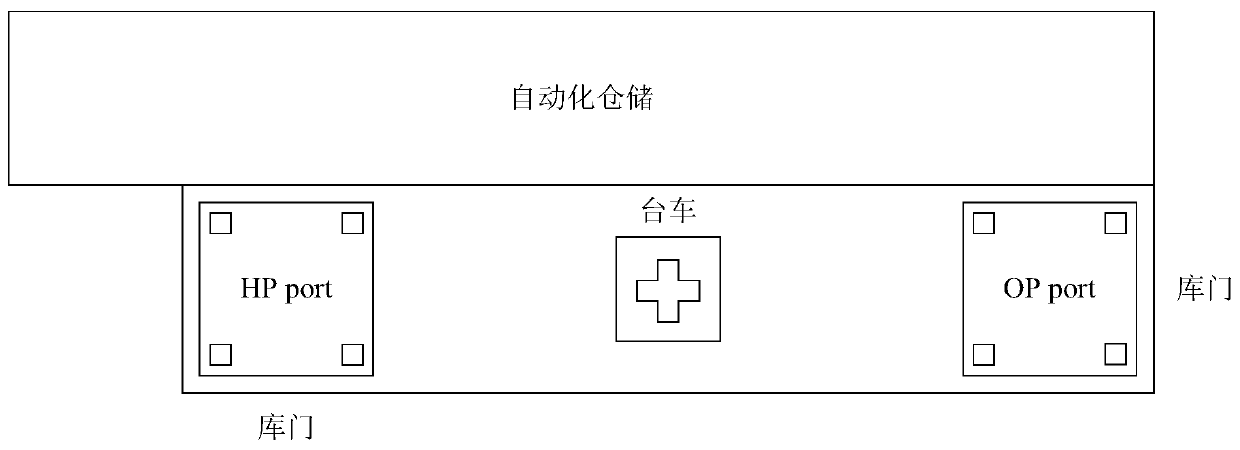

[0122] Specifically, the above-mentioned first area may be an area for identifying the glass cassette when the glass cassette is put into storage, such as figure 1 As shown, the opening direction of the warehouse door can be in the running direction or the running side of the pick-and-place machine Crane. When the opening direction of the warehouse door is in the running...

Embodiment 3

[0134] According to an embodiment of the present invention, a system embodiment of a glass cassette processing system is provided.

[0135] Figure 11 is a schematic diagram of a processing system for a glass cassette according to an embodiment of the present invention, such as Figure 11 As shown, the system includes:

[0136] The photoelectric sensor 111 is arranged in the first area of the inner suspension device, and is used to identify the placement direction of the glass cassette when the glass cassette is detected in the first area, wherein the placement direction Including: forward placement and reverse placement.

[0137] Specifically, the above-mentioned first area may be an area for identifying the glass cassette when the glass cassette is put into storage, such as figure 1 As shown, the opening direction of the warehouse door can be in the running direction or the running side of the pick-and-place machine Crane. When the opening direction of the warehouse doo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com