Stereoscopic warehouse intelligent access method and device for industrial robot practical training

A technology of industrial robots and three-dimensional warehouses, which is applied in the field of intelligent storage and retrieval of three-dimensional warehouses for industrial robot training, which can solve the problems of mechanical rigidity, inability to realize continuous operation of multiple storage locations, and inability to meet the needs of personnel training, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In the prior art robot storage and retrieval practice training, the trajectory of the robot is designed in advance, which cannot realize the access of any storage location, and cannot realize intelligent access. In order to realize the warehouse-in of any designated warehouse location number, it is necessary to improve the existing access method of the three-dimensional warehouse. The technical scheme of the present invention can realize the storage of materials in any vacancy, and the execution program of the robot has only one program, realizing intelligent access; it can realize the automatic storage or delivery of materials with multiple storage location numbers, and the storage of materials can be set arbitrarily Or the total number of warehouses, the robot continuously executes the warehouse-in action to form a continuous production process and realize intelligent access.

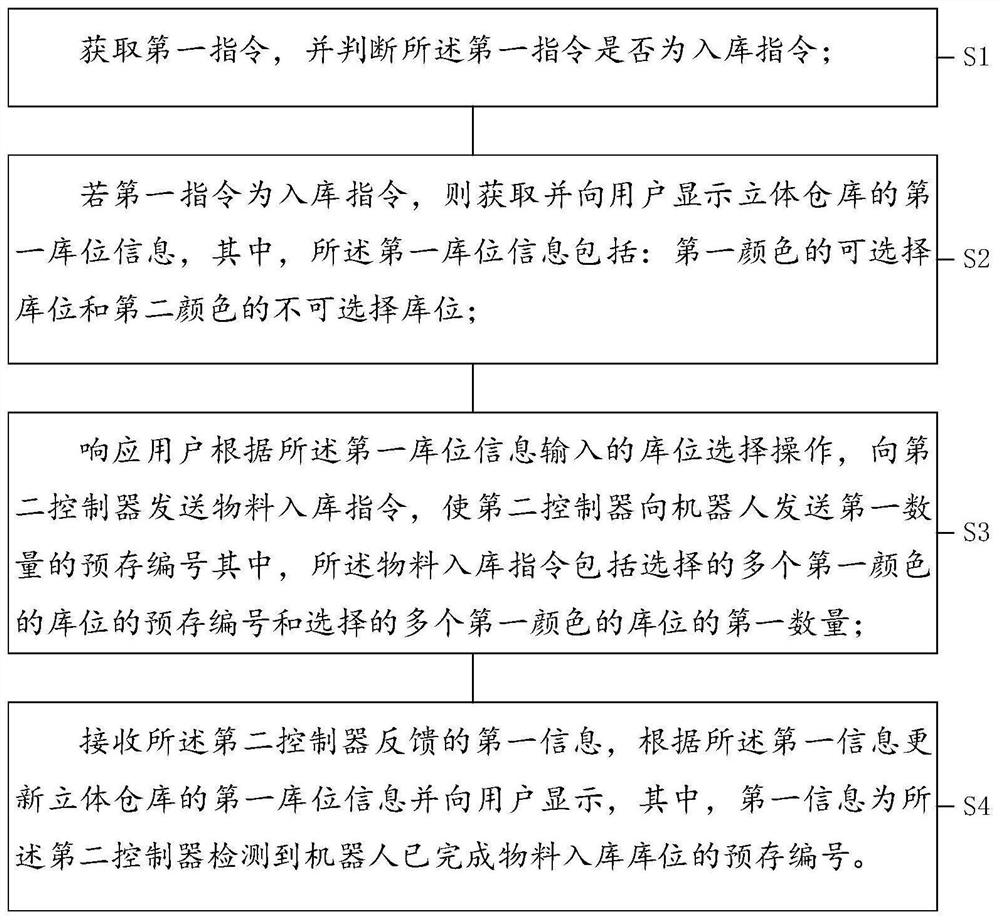

[0052] Such as figure 1 As shown, the present invention discloses a three-dimensional ware...

Embodiment 2

[0104] The invention also discloses a three-dimensional warehouse intelligent access method for industrial robot training, including:

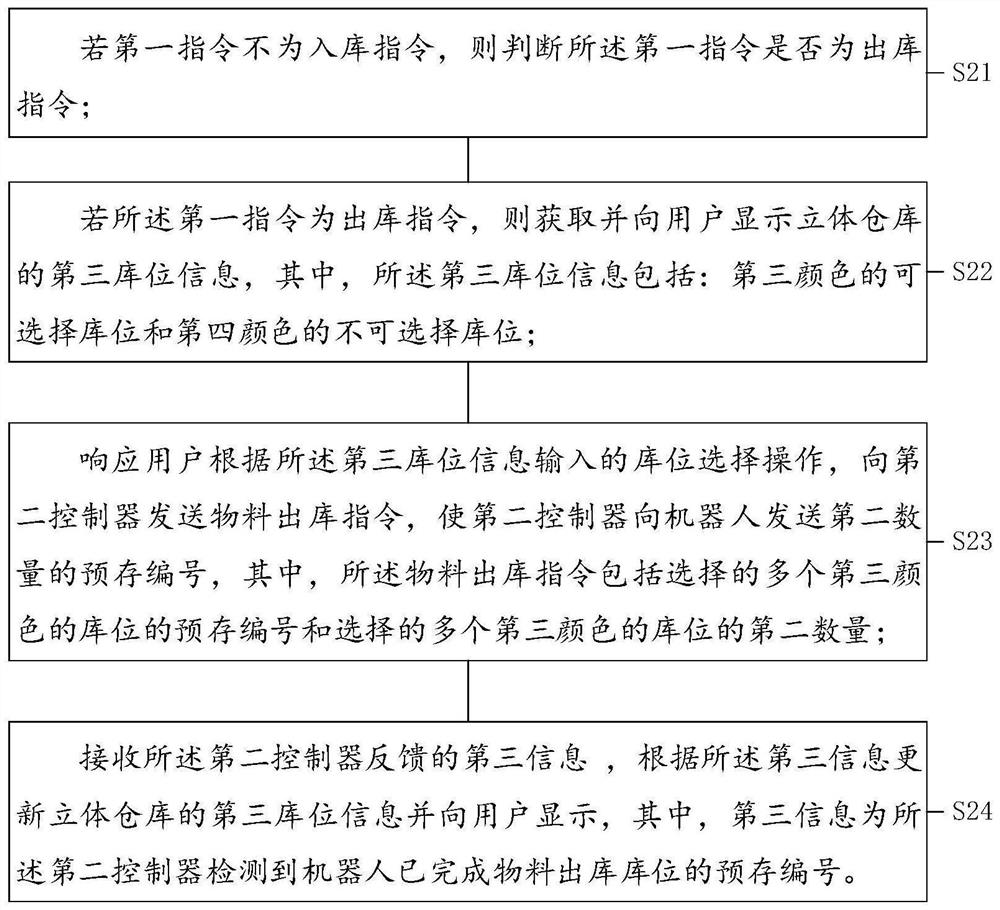

[0105] receiving a material warehousing instruction sent by the first controller, and sending a first quantity of pre-stored numbers to the robot, wherein the material warehousing instruction is a library input by the first controller in response to the user according to the first location information Generated by a location selection operation, the material entry instruction includes the pre-stored numbers of the selected storage locations of the first color and the first quantity of the selected storage locations of the first color; the first storage location information includes : selectable storage locations of the first color and non-selectable storage locations of the second color; the first storage location information is obtained from the three-dimensional warehouse when the first controller judges that the first order is a storage orde...

Embodiment 3

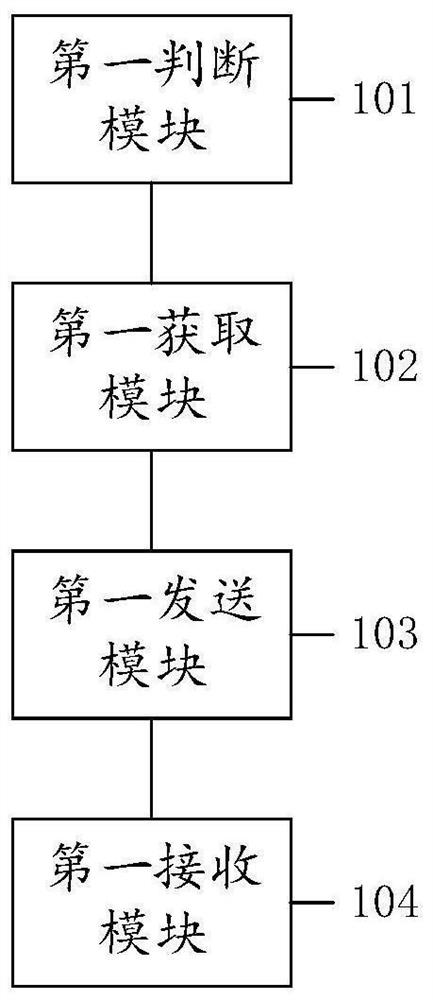

[0111] The present invention also discloses a three-dimensional warehouse intelligent access device for industrial robot training, including: a first judgment module 101 , a first acquisition module 102 , a first sending module 103 and a first receiving module 104 .

[0112] The first judging module 101 is configured to acquire a first instruction, and judge whether the first instruction is a storage instruction;

[0113] The first acquiring module 102 is configured to acquire and display to the user the first warehouse location information of the three-dimensional warehouse if the first instruction is a warehouse-in instruction, wherein the first warehouse location information includes: Non-selectable locations for selected locations and secondary colors;

[0114] The first sending module 103 is configured to send a material storage instruction to the second controller in response to the location selection operation input by the user according to the first location informatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com