Coil-discharging mating device of dividing and cutting machine

A slitter and reel technology, which is applied in the direction of winding strips, transportation and packaging, thin material handling, etc., can solve the problems of unable to keep up with the progress of production, unable to work continuously, and labor consumption, etc., to achieve a stable structure , Improve processing efficiency, not easy to damage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

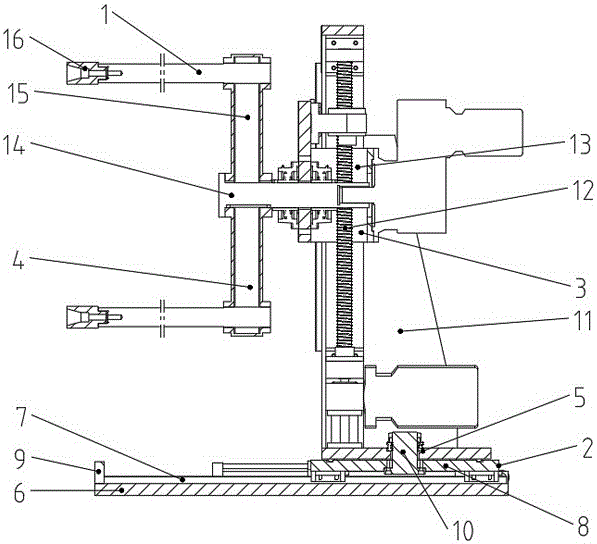

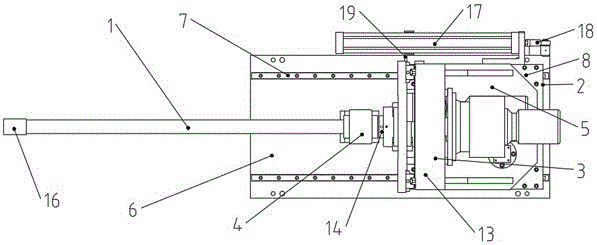

[0013] according to figure 1 , 2 Describe the specific embodiment of the present invention, including the roll hanging rod of the slitter, and the unloading device arranged on one side of the slitting machine, the unloading device includes a connection rod 1, a disengagement displacement structure 2, a lifting structure 3. The overturning structure 4 and the rotating structure 5, the detachment displacement structure 2 includes a bottom plate 6 fixed on the bottom surface, the bottom plate 6 is connected with a track 7 parallel to the axial direction of the reel hanging rod, and the sliding frame on the track 7 is provided with Unloading rack bottom plate 8, limit block 9 is fixed on the track 7, the rotating structure 5 includes a rotating shaft 10 fixed on the unloading rack base plate 8, and an unloading main shaft coaxially installed on the rotating shaft 10. Support 11, the lifting structure 3 includes a screw rod 12 installed on the unloading main bracket 11 and an up a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com