Highly-efficient oil-water separating device

An oil-water separation device and oil-water separation technology, which are applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of complicated wastewater treatment process, long treatment time and long time. , to achieve the effect of saving processing time, fast processing speed and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

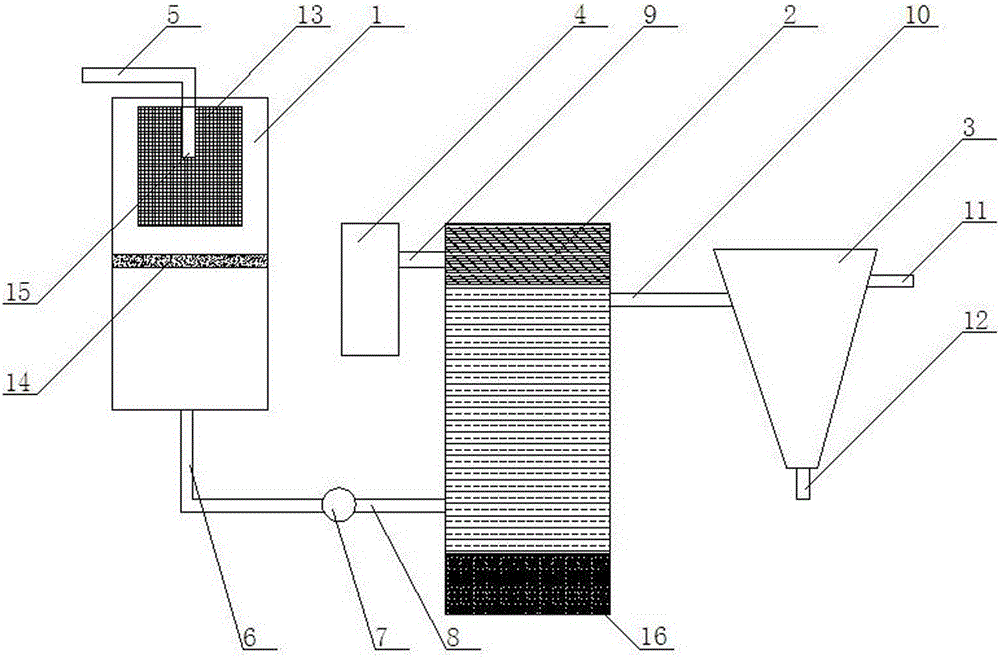

[0014] A high-efficiency oil-water separation device, including a pretreatment chamber 1, an oil-water separation chamber 2, a conical cyclone separator 3, and an oil collection chamber 4, the upper end of the pretreatment chamber 1 is equipped with a water inlet pipe 5, and the pretreatment chamber 1 is connected to the water pump 7 through the first pipeline 6 at the bottom, the water pump 7 is connected to the lower left end of the oil-water separation chamber 2 through the second pipeline 8, and the upper left end of the oil-water separation chamber 2 is connected to the oil collection chamber 4 through the third pipeline 9, The upper right end of the oil-water separation chamber 2 is connected to the upper left end of the conical cyclone separator 3 through the fourth pipeline 10, the upper right end of the conical cyclone separator 3 is equipped with an oil discharge pipe 11, and the conical cyclone separator Drain pipe 12 is installed at the bottom of device 3 .

Embodiment 2

[0016] The upper end of the pretreatment chamber 1 is equipped with an impurity isolation basket 13 and a porous medium filter material layer 14 , and one end nozzle 15 of the five inlet pipes is inserted into the impurity isolation basket 13 .

Embodiment 3

[0018] The bottom end of the oil-water separation chamber 2 is equipped with a bubble generator 16 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com