A recycled concrete produced from recycled aggregate

A technology of recycled concrete and recycled aggregate, applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem of insufficient utilization of recycled aggregate, low proportion of recycled aggregate, and the use of recycled aggregate Unscientific and other issues, to achieve good performance, improve utilization, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

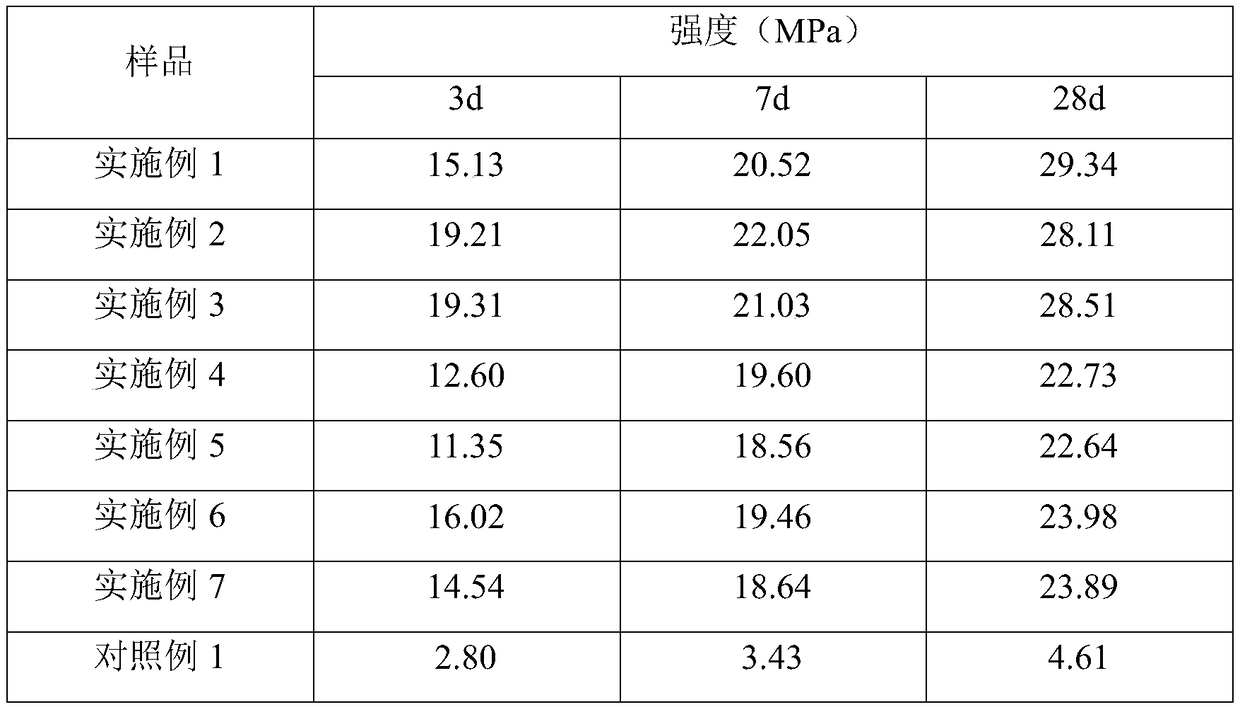

Examples

preparation example Construction

[0024] The preparation method of the regenerated coarse and fine aggregate of the present invention is as follows: sorting construction waste, collecting concrete waste and brick waste in the construction waste respectively, then crushing and screening the concrete waste and brick waste respectively, and then Concrete waste and brick waste in the same particle size range are mixed (recycled coarse aggregates continue to mix coarse aggregates in different particle size ranges), the mass percentage of concrete waste is not more than 30%, and the obtained recycled coarse and fine aggregates are mainly Raw material technical indicators are as follows:

[0025] 1. Moisture content:

[0026] Recycled Coarse and Fine Aggregate

moisture content

Recycled fine aggregate (0-5mm)

10%-12%

Regenerated Coarse Aggregate (5-20mm)

6%-8%

Regenerated coarse aggregate (20-31.5mm)

4.5%-5.5%

[0027] 2. Particle Grading

[0028] Particle gradation: T...

Embodiment 1

[0037] A kind of recycled concrete produced by using recycled aggregate, which is composed of the following raw materials in mass percentage: 53.18% recycled coarse aggregate, 17.72% recycled fine aggregate, 18.77% P.O.42.5 cement and 10.33% water; wherein, the recycled coarse aggregate is composed of The mass percentage is 40.05% of the recycled coarse aggregate with a particle diameter of 5-20mm and the mass percentage is 59.95% of the recycled coarse aggregate with a particle diameter of 20-31.5mm.

Embodiment 2

[0039] A kind of recycled concrete produced by using recycled aggregate, which is composed of the following raw materials in mass percentage: recycled coarse aggregate 51.93%, recycled fine aggregate 19.88%, P.O.42.5 cement 18.18% and water 10.01%; wherein, recycled coarse aggregate is composed of The mass percentage is 35.75% of the recycled coarse aggregate with a particle diameter of 5-20mm and the mass percentage is 64.25% of the recycled coarse aggregate with a particle diameter of 20-31.5mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com