A kind of environment-friendly automobile shock absorber oil and preparation method thereof

A shock absorber oil, environmentally friendly technology, applied in the petroleum industry, lubricating compositions, etc., can solve the problems of harming human health, fast attenuation, polluting the environment, etc., and achieves good oxidation resistance, reduced corrosion, and low odor. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

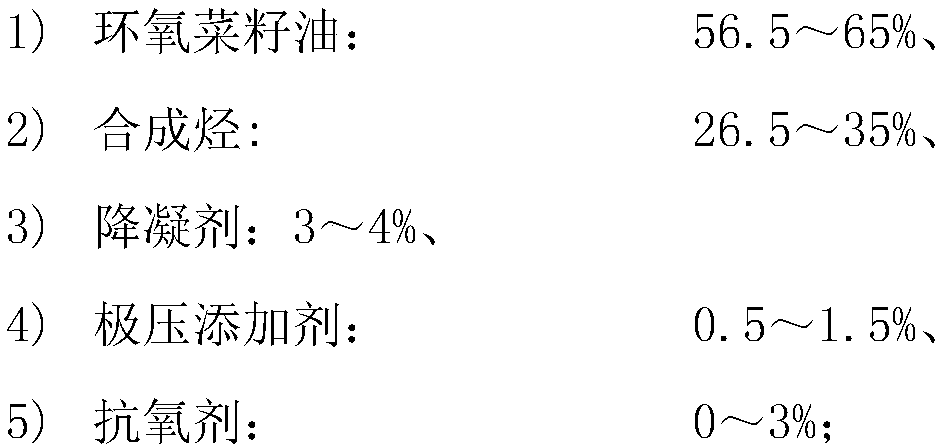

[0050] A kind of environment-friendly automobile shock absorber oil, it is made up of the component of following percentage by weight:

[0051] PAO: 30.0%;

[0052] 4,4'-methylenebis(2,6-di-tert-butylphenol): 1%;

[0053] Zinc dialkyldithiocarbamate: 1%;

[0054] Tricresyl phosphate: 0.5%;

[0055] P-120 organophosphorus nitrogen compound: 0.5%;

[0056] Polymethacrylate: 4%;

[0057] T901: 20ug / g;

[0058] T912: 30ug / g;

[0059] The rest is 63.0% of epoxy rapeseed oil.

[0060] Further, the synthetic hydrocarbon is a low-viscosity PAO whose kinematic viscosity at 100°C is 2±0.2mm 2 / s.

[0061] The present invention also provides the preparation method of above-mentioned a kind of environment-friendly automobile shock absorber oil, comprises the following steps:

[0062] 1) Pour epoxy rapeseed oil and synthetic hydrocarbon into a blending kettle with a stirrer, stir for 8-12 minutes to make synthetic base oil;

[0063] 2) adding antioxidant and extreme pressure agen...

Embodiment 2

[0078] This embodiment is basically the same as Embodiment 1, the difference is that:

[0079] An environment-friendly automobile shock absorber oil, which is composed of the following components in percentage by weight: PAO: 30%;

[0080] 2,2'-methine bis(4-methyl tert-butylphenol): 2%;

[0081] Triaryl phosphate: 1%;

[0082] Polyacrylate: 4%;

[0083] T901: 20ug / g;

[0084] T912: 30ug / g;

[0085] The rest is 63% of epoxy rapeseed oil.

[0086] Further, the synthetic hydrocarbon is a low-viscosity PAO whose kinematic viscosity at 100°C is 2±0.2mm 2 / s.

[0087] Further, the epoxy rapeseed is composed of the following components in weight percent: rapeseed oil: 49%, glacial acetic acid: 14%, sulfuric acid: 2%, hydrogen peroxide: 30%, sodium hydroxide aqueous solution: 5% %.

[0088] Further, the rapeseed oil has an acid value below 0.2 mgKOH / g and a saponification value of 168-179 mgKOH / g.

[0089] Further, the content of the glacial acetic acid is not less than 99.5...

Embodiment 3

[0095] This embodiment is basically the same as Embodiment 1, the difference is that:

[0096] An environment-friendly automobile shock absorber oil, which is composed of the following components in percentage by weight: PAO: 34.2%;

[0097]N, N'-di-sec-butyl-p-phenylenediamine: 0.8%;

[0098] Dialkyldithiocarbamate: 1.2%;

[0099] Dialkyl phosphite: 1.5%;

[0100] Polymethacrylate: 4%;

[0101] T901: 40ug / g;

[0102] T912: 20ug / g;

[0103] The rest is 58.3% of epoxy rapeseed oil.

[0104] Further, the synthetic hydrocarbon is a low-viscosity PAO whose kinematic viscosity at 100°C is 4±0.2mm 2 / s.

[0105] Further, the epoxidized rapeseed oil and its preparation method are composed of the following components in percentage by weight: rapeseed oil: 49%, glacial acetic acid: 14%, sulfuric acid: 2%, hydrogen peroxide: 30%, Sodium hydroxide aqueous solution: 5%.

[0106] Further, the rapeseed oil has an acid value below 0.2 mgKOH / g and a saponification value of 168-179 mg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| cloud point | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com